The affordability of 3D printing has changed the way I modify my vehicle. Not long ago if some part didn’t exist that fit my need I had to do without. A lot has changed over the years but how did all this lead me to making my own parts? How did I end up making this?

Before 2010 manufacturing my own parts wasn’t a reasonable option.

Charles W. Hull invented the stereolithography printer in 1986. In 1987 you could purchase the SLA-1 Original 3D Printer for about $300,000 UDS. The equivalent in 2023 value is just over a million dollars. For the next 20 years 3D printing and rapid prototyping was was out of reach for most people leaving just the traditional manufacturing process.

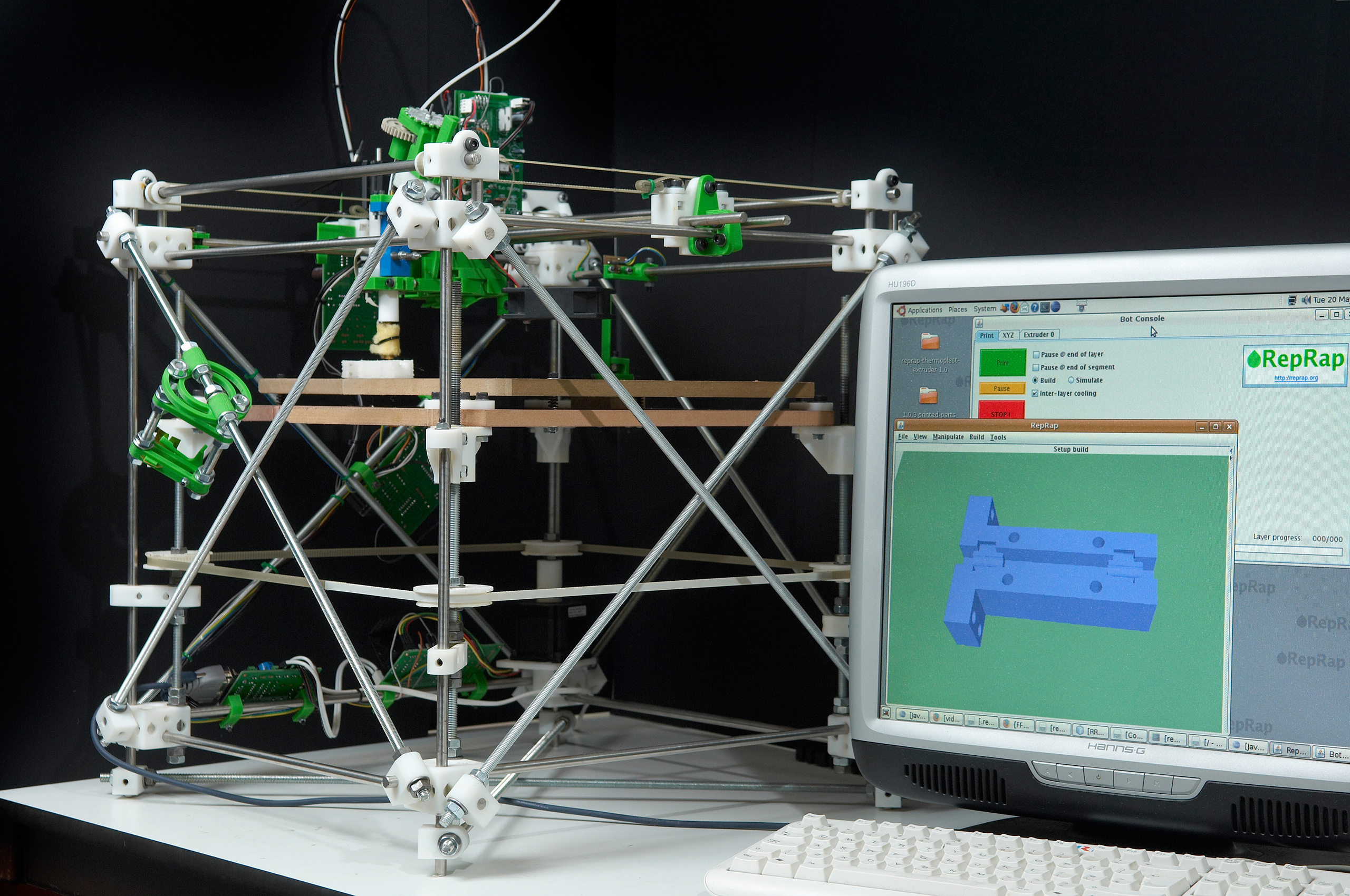

Between 2004 and 2005 the interest in low cost 3D printers skyrocketed when Dr. Adrian Bowyer, a Senior Lecturer in mechanical engineering at the University of Bath in England, introduced the idea of 3D printers that could self-replicate. The project named RepRap (‘REPlicating RAPid prototyper’) was open source and interest in low cost 3D printing spread worldwide.

Source: https://reprap.org/wiki/Darwin

Then the 3D Printing landscape changed in 2009. Charles W. Hull’s patent of stereolithography (SLA) and Stratasys’ patent for fused deposition modeling (FDM) technology expired. New DIY kits became available and competition for the new non-commercial user market drove prices for DIY 3D Printer kits even lower.

2010 and Maker Culture

During the early 2010’s, around the time Formlabs Kickstarter campaign for the FORM 1 began, online 3D printing service companies like Shapeways, Sculpteo, i.materialise, 3D Hubs, etc. moved to capitalize on the growing interest of 3D printing and the emerging market of low production number 3D printing. Offering multiple printing materials and the ability to print larger then a typical DIY 3D Printer. For individuals and small companies who didn’t want to or couldn’t afford to invest in a commercial 3D Printer it offers the capability of rapid prototyping without the upfront cost. By 2018 the 3D printing industry was generating more than $7 billion in revenue.

So here I am

It’s in this environment that I found myself looking for a part that didn’t exist. A Quick Fist mount for a Frontrunner roof rack. Having some CAD experience I was fascinated by the prospect of being able to manufacture my own parts so I dived in.

Not without mistakes of course. There’s an expression “fail fast, fail often” and by that measure my first attempts were an astounding success. If you plan on taking the same dive my advice is to literally start small when using online 3D printing services. You pay as much, if not more, for the volume of the object you wish to print than for the materials. Also invest in a precision measuring tools. Just eyeballing it will get expensive fast.

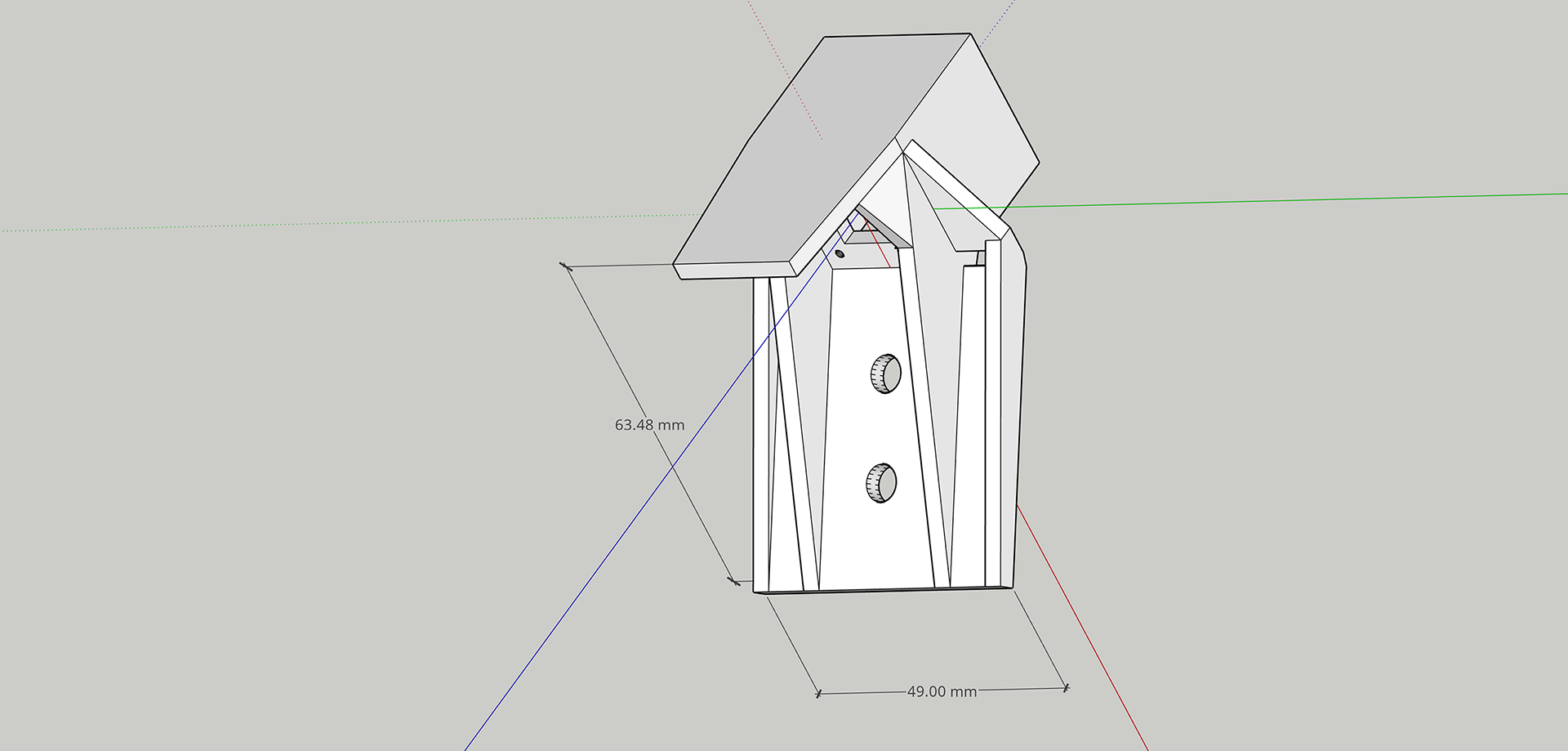

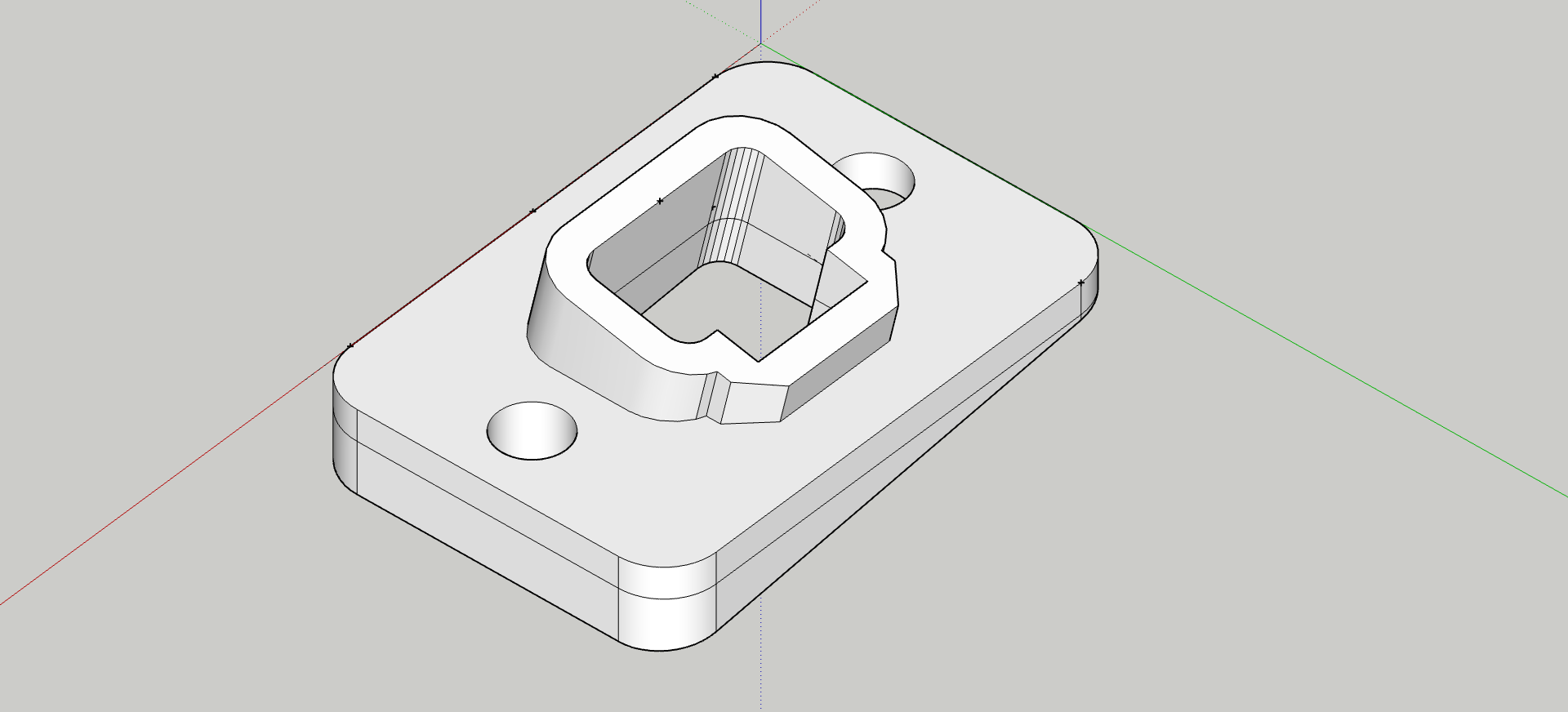

Eventually the incline of the learning curve began to level out. I also found myself in need of another impossible to find part. A relocation kit that worked with the OEM Tacoma backup camera and a custom rear bumper. It took several reprints to get the pitch of the camera correct as well as understanding the tolerances of the materials. Being a relatively small part the experience was worth the cost of the do-overs.

From There to Here by Just Making Stuff

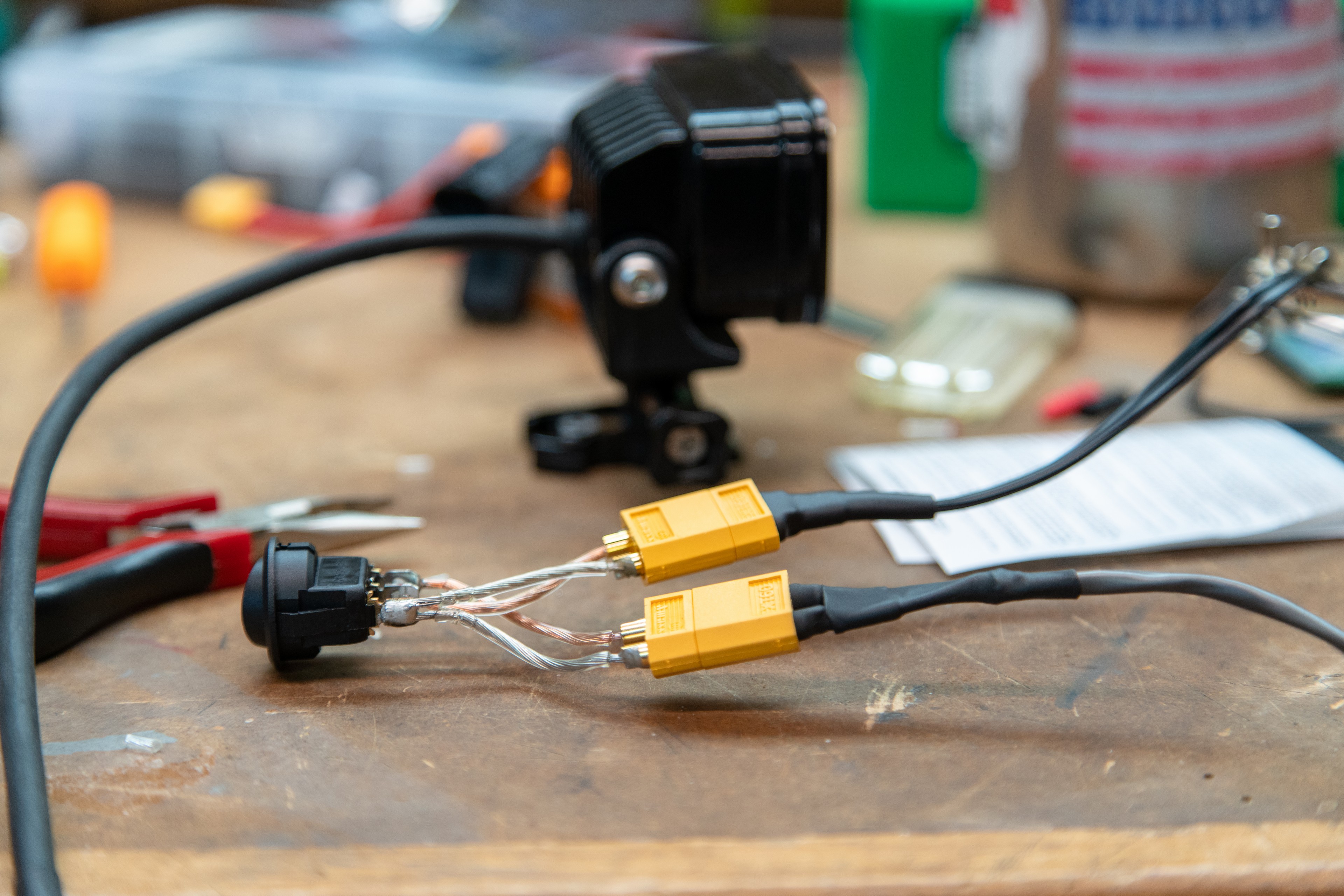

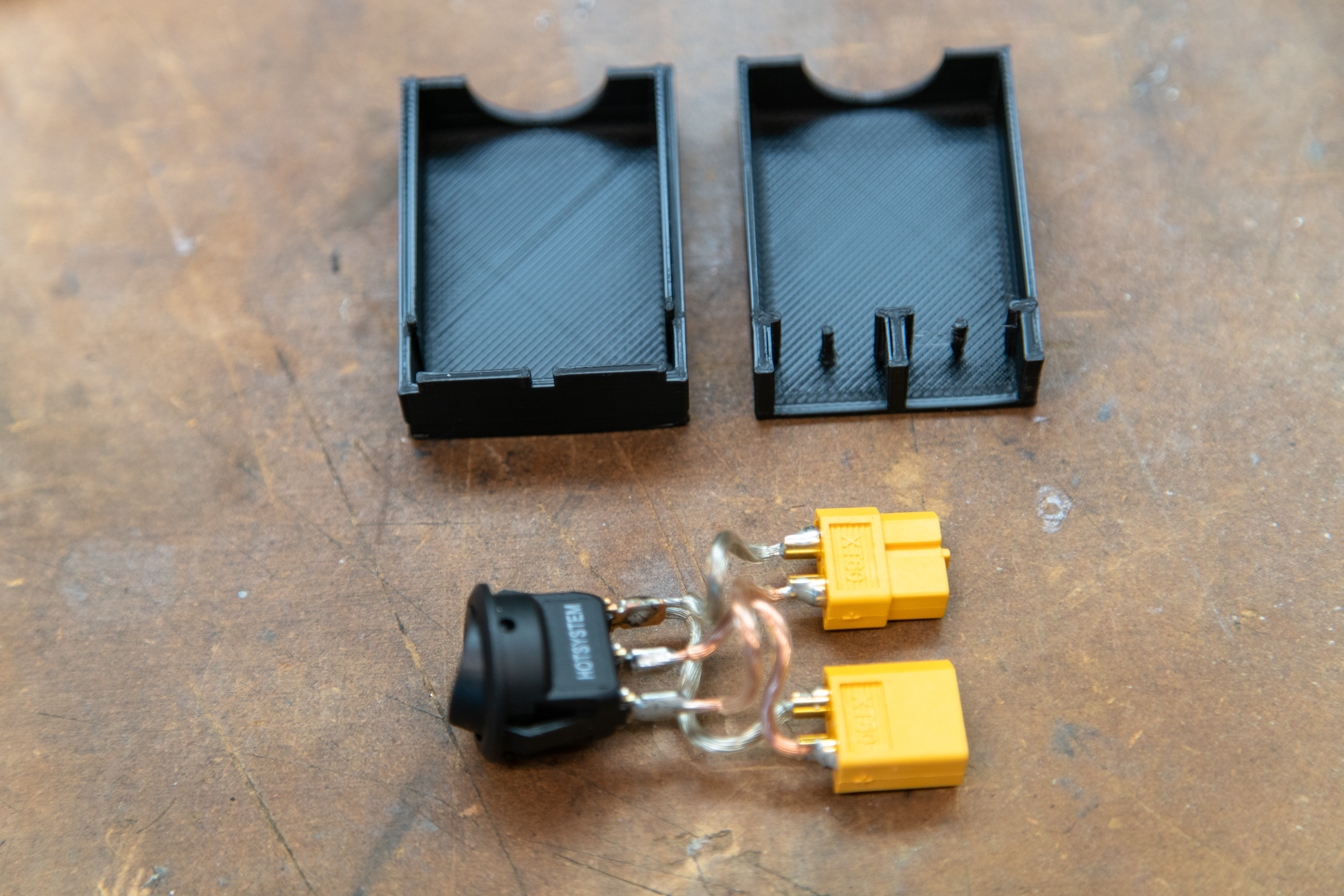

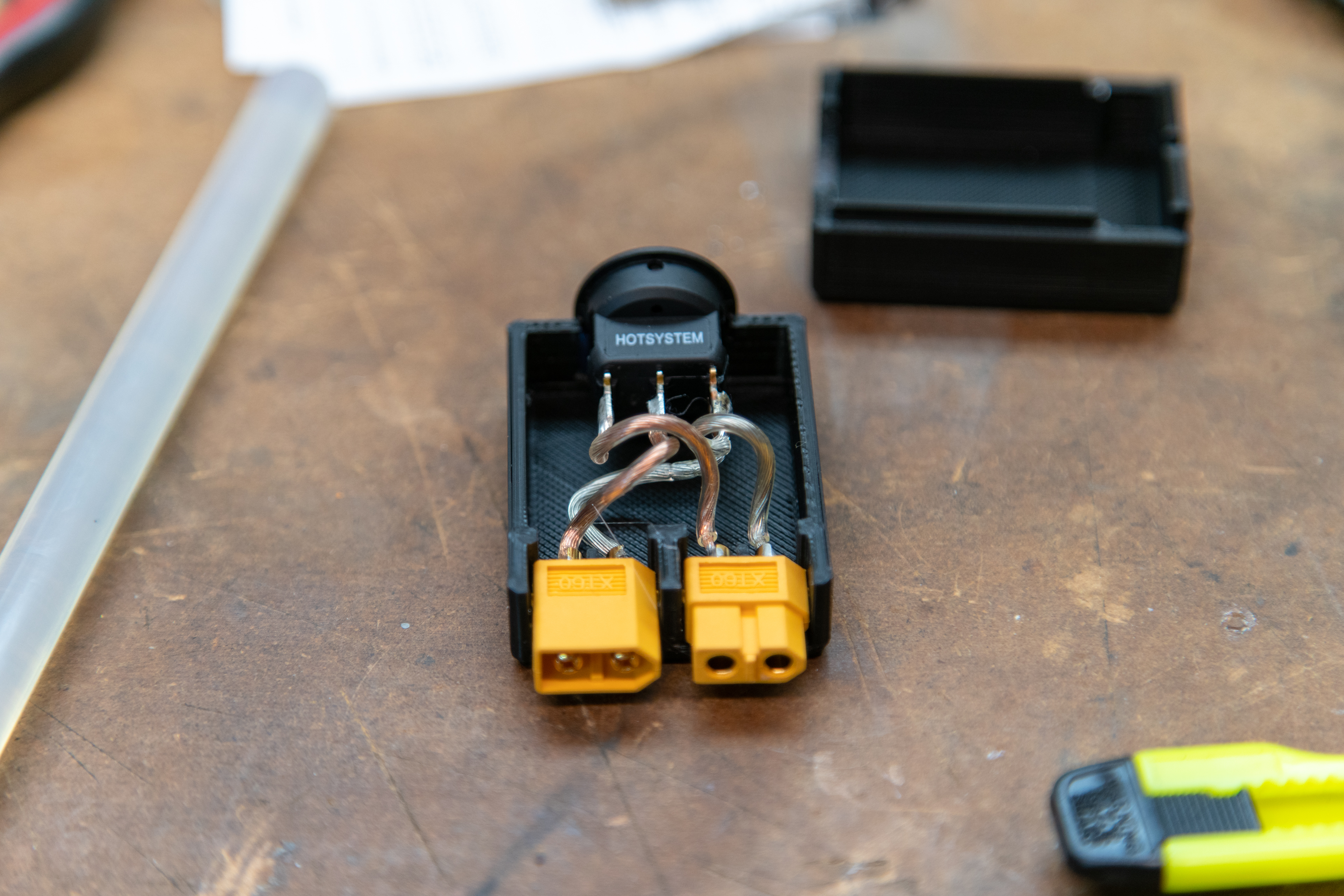

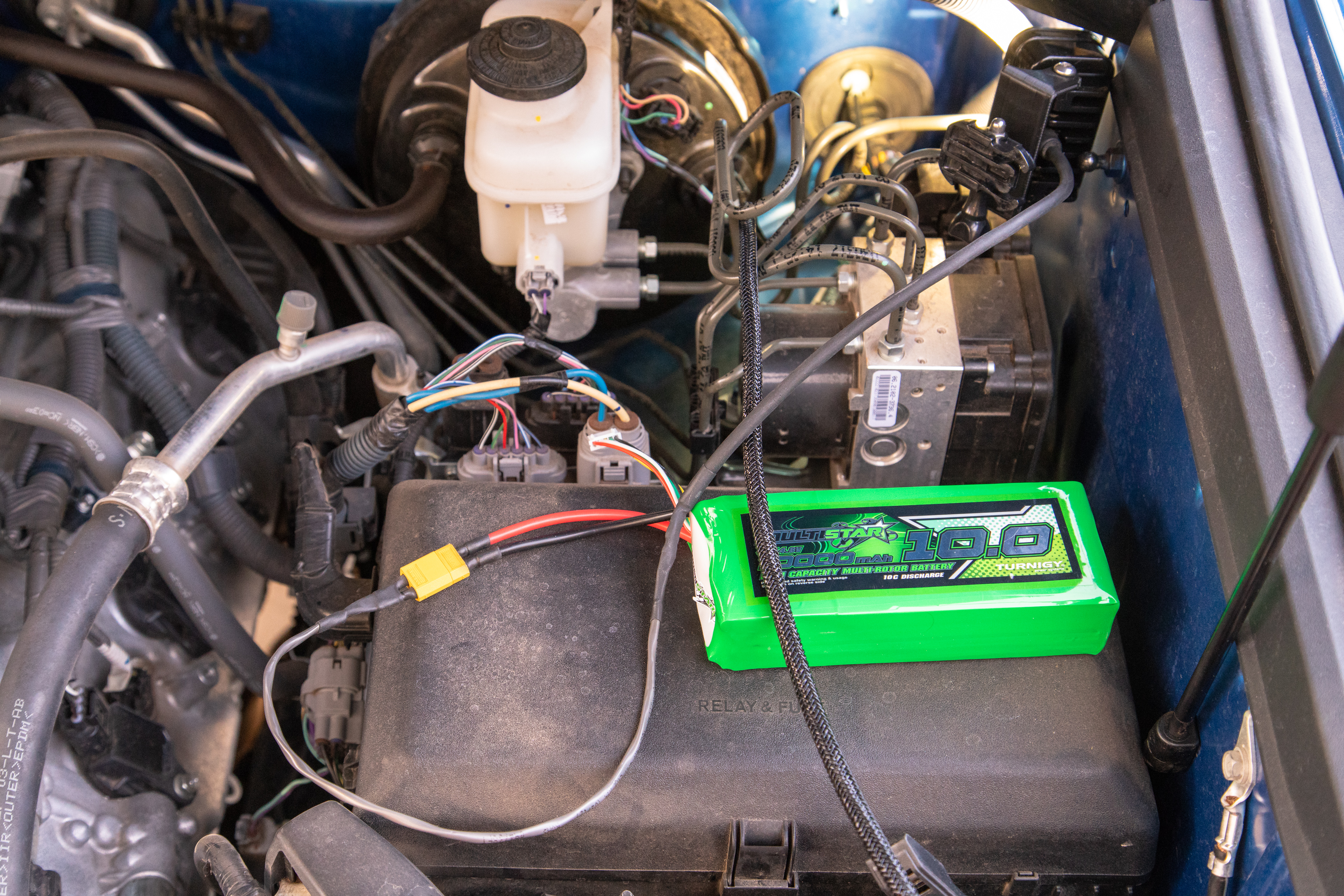

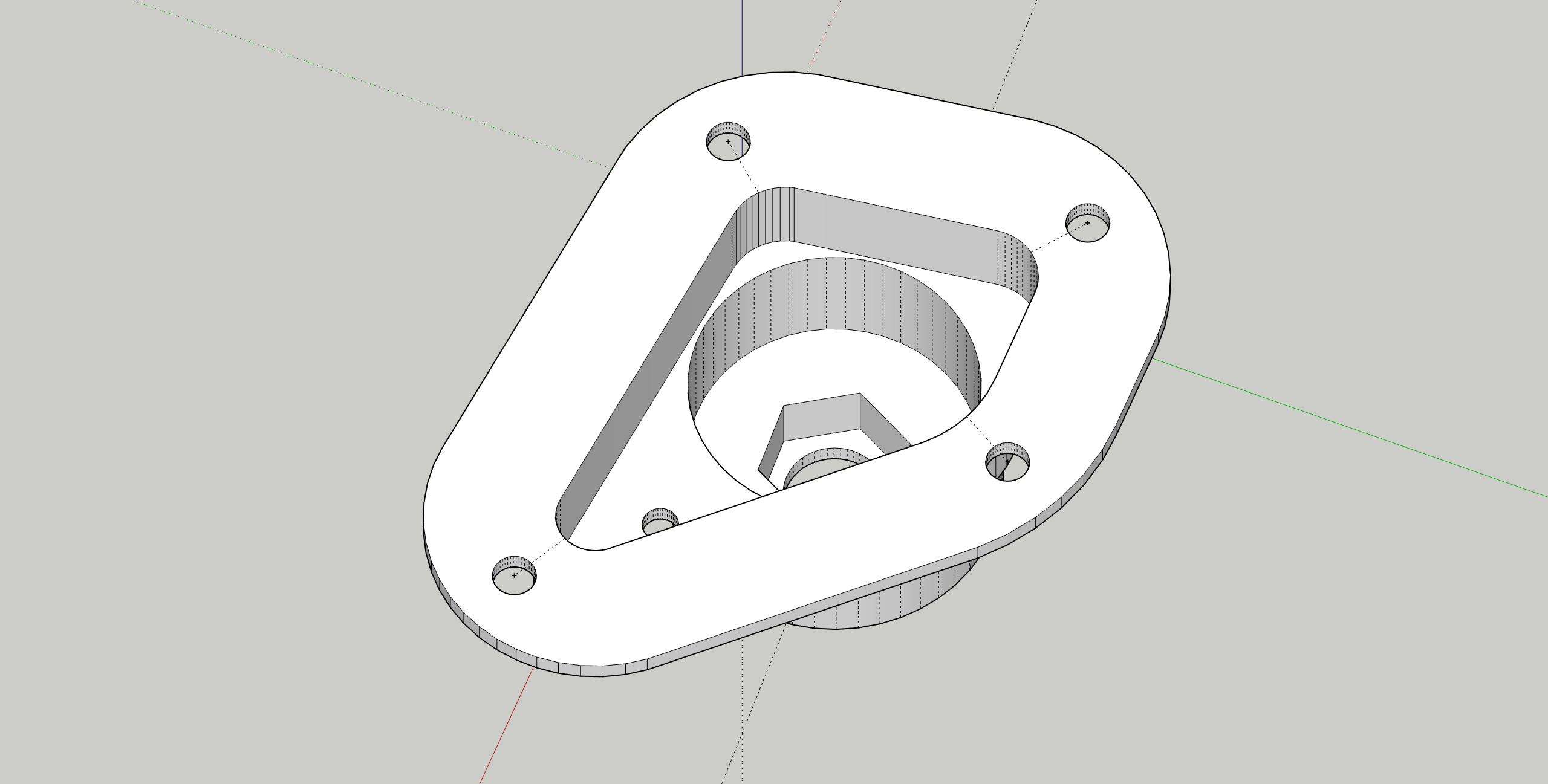

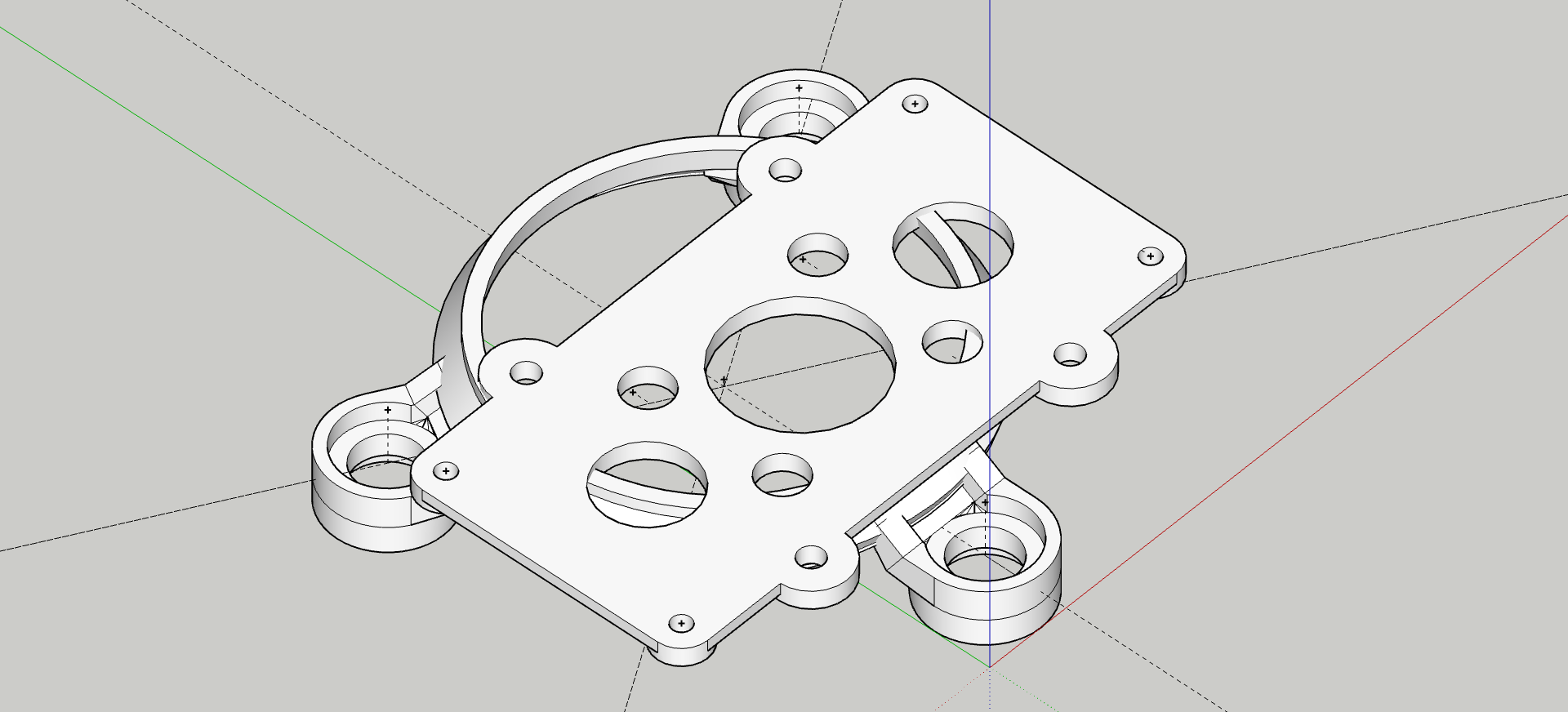

Following is a sampling of the progression of the complexity of the parts I had manufactured. It also highlights a transition into creating parts to address an afterthought to that of being part of the modification from the very start. From filling in a need with a camera relocation mount on a bumper that didn’t have one. To making improvements on something that was satisfactory by cleaning up a solar panel cable pass through for a project that was in progress. To planning the location of a compressor switch and quick disconnect and working the other components in to fit within that design plan.

You need only time to start manufacturing your own parts

3D printing services will vary in costs, materials available, and limitations of the size of the printed object. Online CAD services will vary in the design of the user interface as well as the file formats available for download. Each have their own advantages and disadvantages. Including their location to take advantage of shipping time and/or currency exchange rates.

My current project is a sPOD SourceLT / universal mount for the engine bay of a Subaru Crosstrek. I don’t own a 3D Printer or CAD software. It, and everything I’ve designed and had manufactured, exists through using some of the services I’ve listed below. The lists are by far not exhaustive but they will help you get started.

3D Printing Services

- 3DPRINTUK – UK

- i.materialise – Belgium

- MakeXYZ – USA

- Protolabs – USA

- Sculpteo – France

- Shapways – Holland / USA

- Stratasys Direct – USA

- Xometry – USA

I’ve used Sculpteo and Shapeways printing services. Both are similar in printing materials available and in price with Sculpteo being less expensive than Shapeways with some materials. Of the browser-based CAD programs I’ve only used Sketchup. Mostly because I’ve used it since Google acquired (and later sold) the original creator @Last Software and all its quirks are familiar to me.

Further Reading

- Meet the Maker – Covers the TAZ 6 3D Printing machine and some of the parts created at home to improve and/or repair gear.

- Meet the Maker Part II – Continues with creating a GoPro magnetic mount.

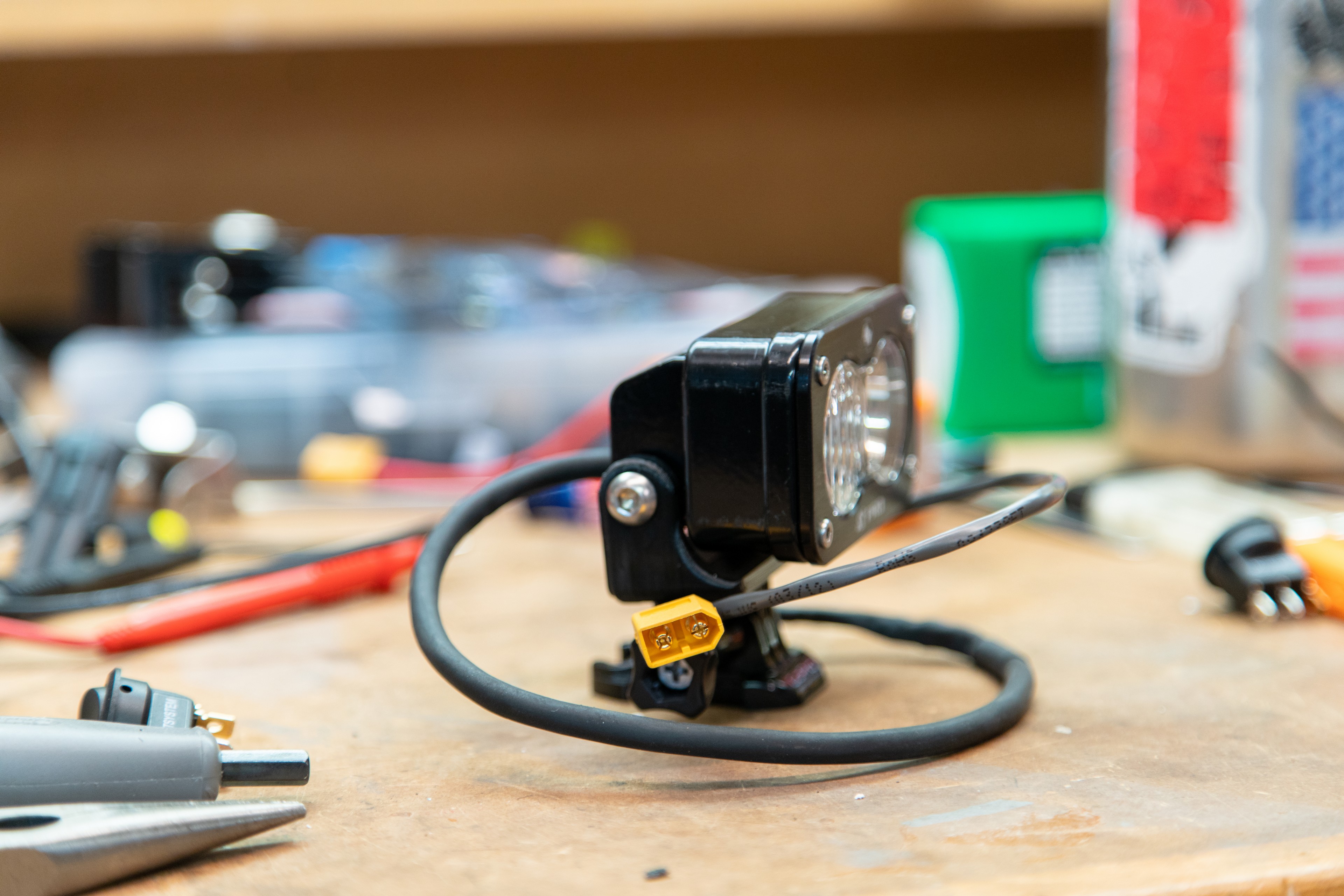

- DIY: The Ultimate Headlamp (Or Practically Anywhere Lamp) – Using a Baja Designs S2 Pro. 3D printer files are available in the article.

- Hack The Pandemic – Supporting Healthcare and Law Enforcement professionals by manufacturing PPE equipment in your home via 3D printing.

We want your input

We invite you to participate and constructively contribute. Are you using a different online service that’s not listed here that you want to recommend? Let us and the readers know by joining our community.

FULL DISCLOSURE: The products and services mentioned in this article were paid for by the author.