As lock downs are lifting, I wanted to stop and reflect on some new hobbies I’ve been keeping busy with. The activities are overland-related and should improve your overall experience on your next trip.

Build a Tiny Truck R/C Crawler

This is not your childhood RadioShack R/C car. The kits today made by Traxxas, RC4WD, and Axial Racing will have you doing a double take. Don’t believe me? Check out @scalebuildersguild on Instagram. These are 1/10th scale 4wd vehicles complete with differentials, solid axles, and even lockers. Not unlike our overland vehicles, each platform offers different advantages and challenges.

The biggest factor in choosing a platform is which body style you find most appealing. Everything is available from classic Land Rovers, Blazers and Broncos to modern Jeeps with lots in between. Can’t find your exact rig? 3D printing has created a niche market for builders to create 5th Gen 4Runners, 3rd Gen Tacomas, and many others.

R/Cs come ready-to-run (“RTR”) or as kits, which are little more than a bag of parts. Limitless upgrades include metal bumpers and sliders, waterproof electronics, and scale accessories like Hi-Lift jacks, roof racks, and even remote controlled electric winches. The downside is these R/Cs aren’t cheap. Expect to shell out $500+ to get something special.

The manufacturers provide surprising customer support and there are loads of dedicated forums and YouTube channels to get you inspired. Wondering what kit I’m running? I went with the RC4WD Gelandre II, which is a solid body design.

What do you do after you build your R/C? Show it off, of course! There are driving skill and build competitions all over the US, including the RC4WD Tiny Truck Challenge Uwharrie hosted by BowHouse RC (bowhouserc.com) at the Big Creek trail system in North Carolina. Windrock Park in Tennessee (windrockpark.com) has a beautiful and technically challenging obstacle course that will inspire you to build one of your own in your backyard. A wheelbarrow of stones, sand, and firewood can build a great backyard course. Don’t forget to air down!

Learn to Play the Guitar

Besides sipping on your favorite bourbon, nothing beats a good campfire guitar session to relax into the evening. I’ve always wanted to play and have at least a couple of half-baked failed attempts under my belt as a teenager.

Like all of my endeavors, I went in with both feet buying an electric followed by an acoustic guitar within a couple of months. While one isn’t a substitute for the other, the acoustic is best suited for life on the road. Look for a travel guitar that is 3/4 size for the best balance of compactness and tone. The Taylor GS Mini (taylorguitars.com) is the gold standard for travel guitars and is designed to fit in the overhead bin of an airplane, not that you’ll need to do that in our lifestyle.

These guitars aren’t toys, they range from about $500 to just under $1,000 depending on the tonewood. You can always buy a less expensive or used guitar if you’re not ready to drop that amount of cash. I went with a highly recommended teacher, Chris Holly (chrishollymusic.com), who was able to adapt his business to an online format as pandemic restrictions tightened.

Really want to impress people? Start out learning the blues; a simple shuffle, turn around, then a few pentatonic scales will go a long way to sounding like something your friends will tap their feet to. Trust me, I’ve learned a dozen sounds since January and unless you’re ready to sing (read: pat your head and rub your belly), few people are going to recognize the rhythm guitar sections from ‘You Can’t Always Get What You Want’ and ‘Every Rose has its Thorns’. But if you can belt out ‘Sweet Home Alabama’, ‘Come as You Are’, and ‘Mary Jane’s Last Dance’ it will take you a little further, but nothing (at least to me) will beat Eric Clapton’s ‘Before You Accuse Me’. Likely the least famous song I listed, but it will work the best when passing the guitar around the fire. Don’t forget to bring your picks, capo, and tuner!

Take up Bushcraft

I love to spend my couch time watching YouTube bushcraft videos. We load our overland rigs with everything minus the kitchen sink. Wait… Actually, some of us have a kitchen sink, ha! But, how much do we really need? Beefing up your bushcraft skills will teach you to do more with a whole lot less.

My kit is down to about ten essentials not including a great bucket style pack complete with axe sleeve. My pack acts as my bugout bag and I keep it in my truck at all times. Everything goes in the bag, minus your bush knife, which should always be on your belt.

Bushcraft doesn’t mean using a bow drill or flint and steel to start every fire, but it doesn’t hurt to learn. Personally, I keep a film canister with 3-4 cotton balls dipped in Vaseline along with a ferro rod to get my fires going quickly. You’ll need a fix blade bush knife with a square spine (90 degree edge) to create the best spark with your ferro rod. Bushcraft Outfitters (bushcraftoutfitters.com) sells everything you need.

My pack is from the Hidden Woodsman (thehiddenwoodsmen.com). Out of the three hobbies I’ve discussed so far, this has the lowest cost of entry and will immediately improve your outdoor experience. You’ll be making your own chairs and sleeping with just a wool blanket in no time.

Get your Ham Radio License

I got my technicians license a few years back, but it’s a great time for you to study up. Yes, there is an exam, but trust me, it’s not impossible. It’s just challenging enough to provide you with a nice sense of accomplishment. The exam is administered by volunteers who want you to pass and it’s a very low pressure multiple choice exam.

Studying the answers may get you across the line, but won’t necessarily make you a good Ham. I had success with Michael Burnette’s audios books (fasttrackham.com) which are perfect for long hours on the hardpack. Michael teaches in a way that will help you understand the theory, practice, and nuanced etiquette to make you a great ham radio operator.

Amateur radio has every advantage over CB, FRS, and GMRS. The radios are much more powerful (read: you talk further) and the reception is crystal clear with a much smaller antenna. I realize this isn’t the first choice for every trail ride, but as you start to take longer and more remote (even international) expeditions, you’ll find ham radio is your best (if not only) option.

Ham radio isn’t limited to trail comms. Portable low power HF rigs have jaw dropping international range with the right antenna. Are you an extreme adventurer? Check out Summit on the Air (sota.org.uk). It would be unforgettable to transmit from on top of the San Juan Mountains.

Close

I want to hear how you’ve been spending your time in 2020 when not out on the trails. Comment with what you’ve been focused on. I’m always looking for another hobby!

Thankfully, a friend of mine in Colorado was a couple weeks ahead of me in his own effort to make face shields – and picking his brain on how to make it happen was invaluable in getting my project off the ground quickly. Normally, my buddy’s company,

Thankfully, a friend of mine in Colorado was a couple weeks ahead of me in his own effort to make face shields – and picking his brain on how to make it happen was invaluable in getting my project off the ground quickly. Normally, my buddy’s company,

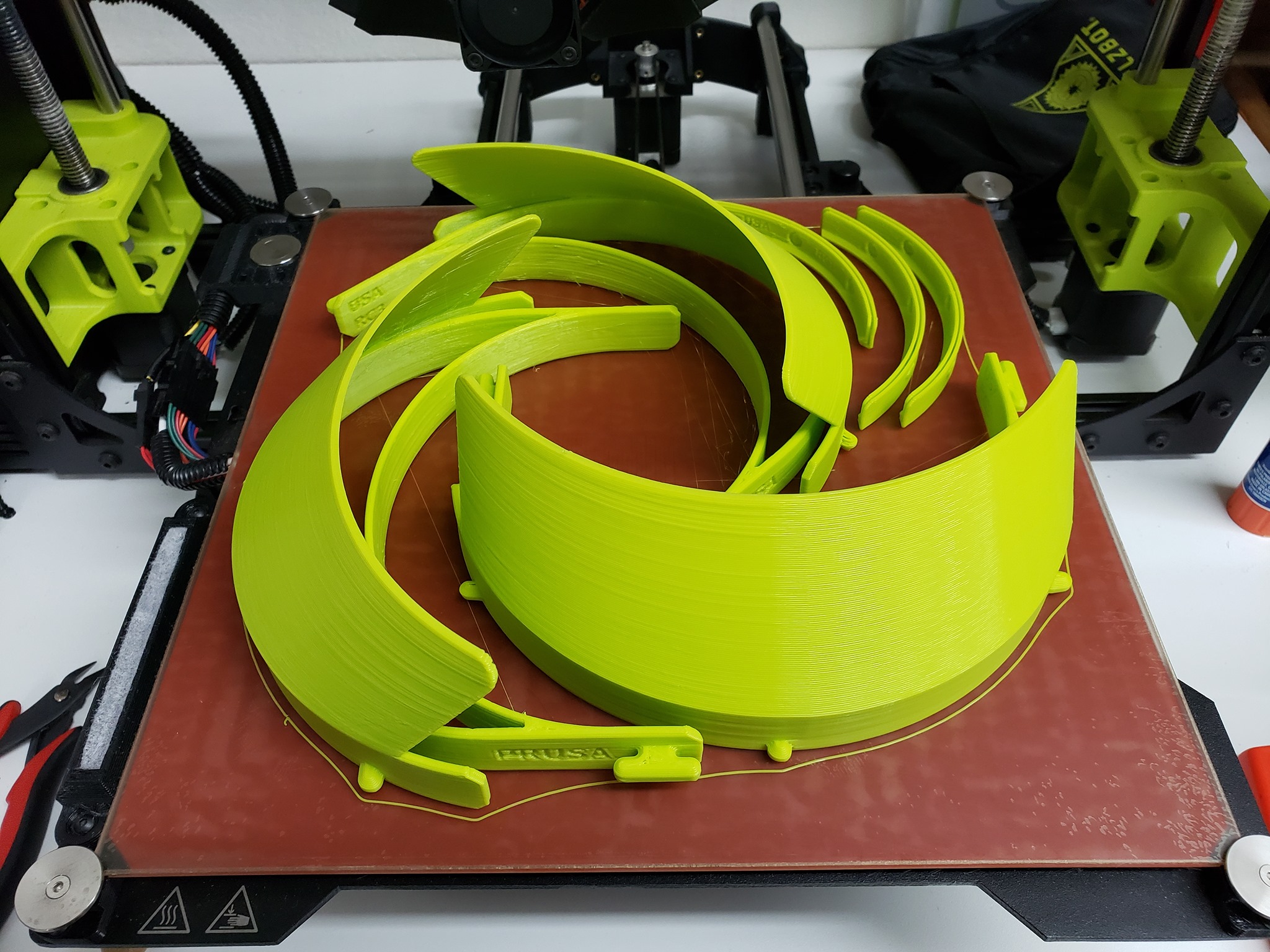

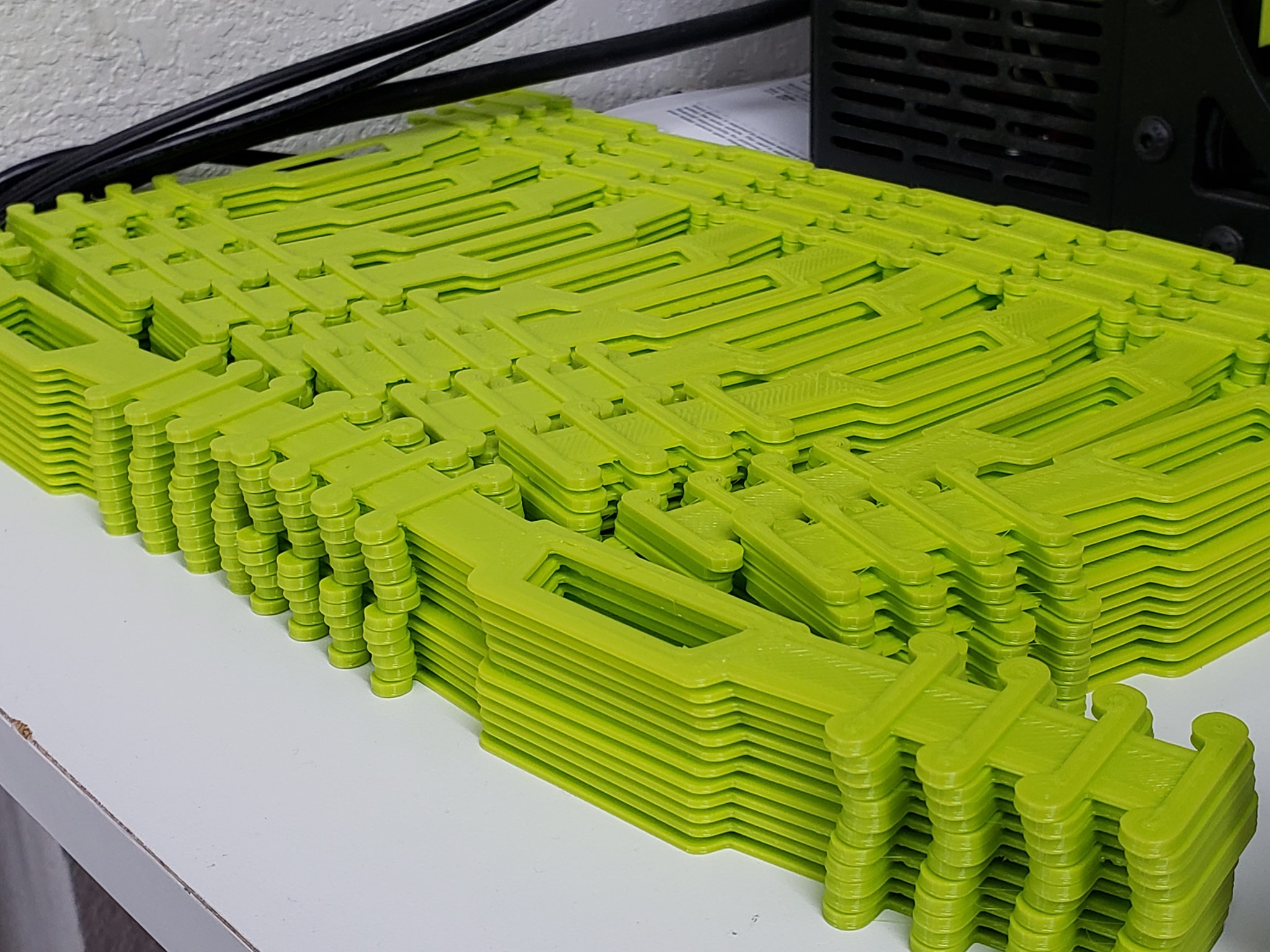

To make quality PPE, you need to print with certain filaments, like PETG, that can withstand the steam autoclave sterilization method that hospitals use. Likewise, all of the other components of the face shield have to be able to withstand sterilization so that the item can be re-used. Thankfully, there are a bunch of folks out there who have already conducted this research and they’re happy to share their knowledge. Thanks internet. The global maker community has come together to crowdsource designs, get them validated by healthcare professionals, and then get tons of these supplies in the hands of the folks who need them.

To make quality PPE, you need to print with certain filaments, like PETG, that can withstand the steam autoclave sterilization method that hospitals use. Likewise, all of the other components of the face shield have to be able to withstand sterilization so that the item can be re-used. Thankfully, there are a bunch of folks out there who have already conducted this research and they’re happy to share their knowledge. Thanks internet. The global maker community has come together to crowdsource designs, get them validated by healthcare professionals, and then get tons of these supplies in the hands of the folks who need them.

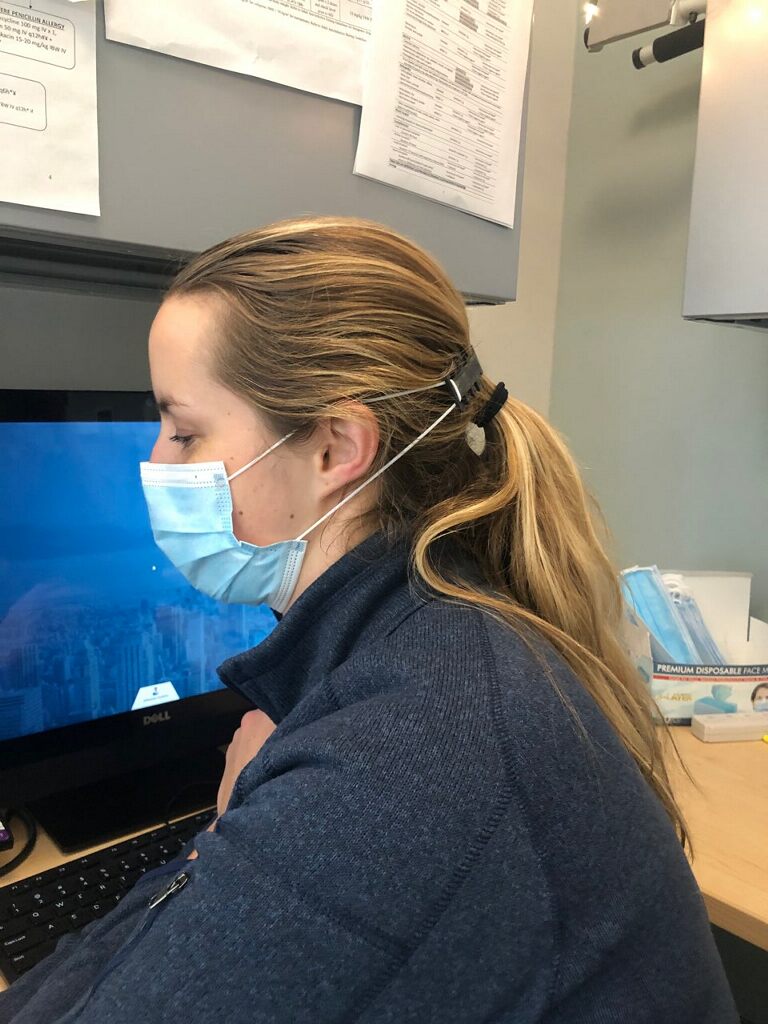

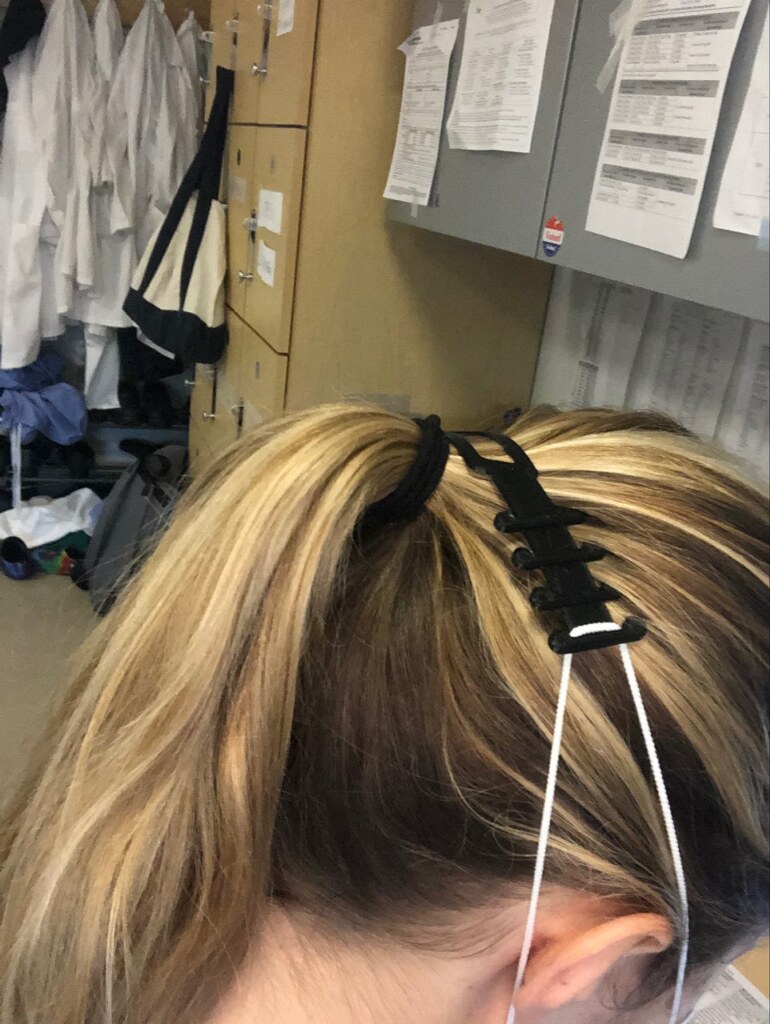

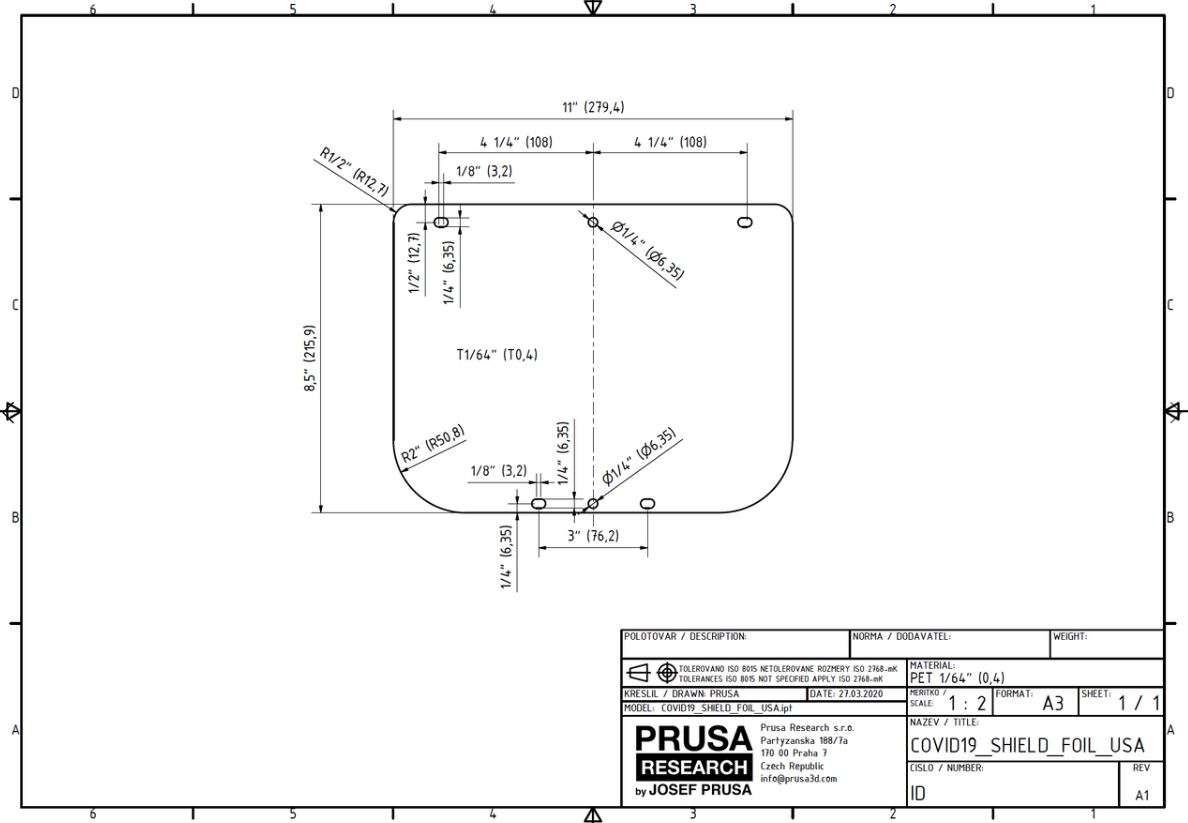

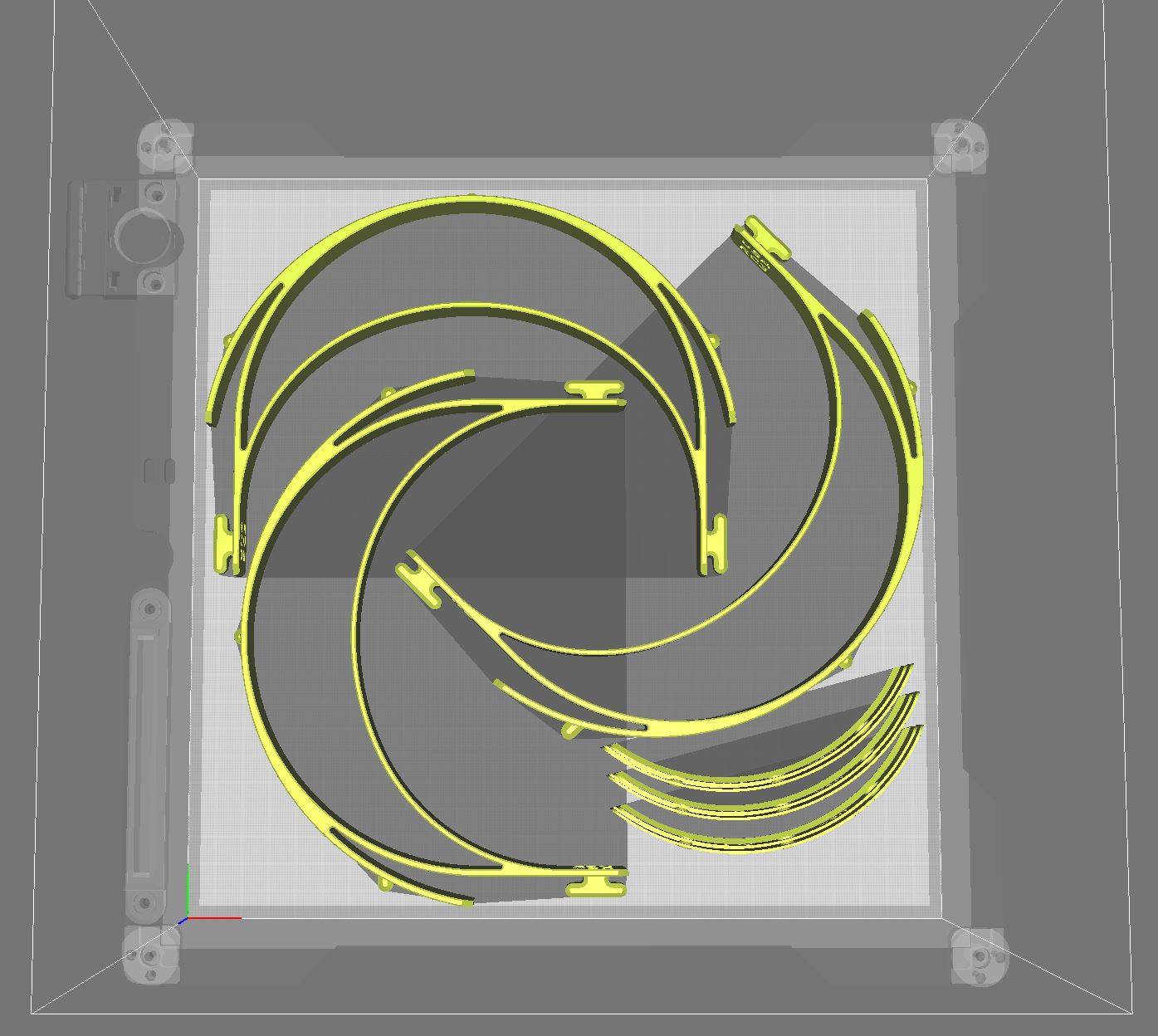

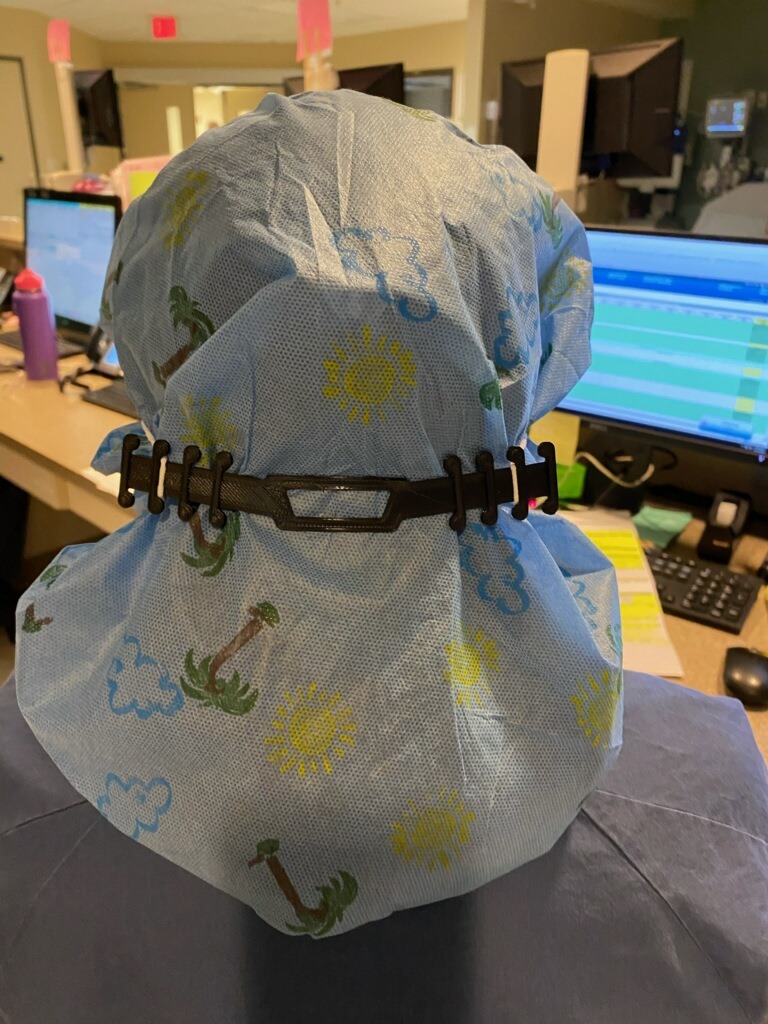

One of the more popular crowdsourced 3D Printed face shield designs is Prusa Research RC3 USA face shield. This design prints relatively quickly and has been optimized using USA standards for things 3-hole punches to make a face shield that’s easily manufactured without special tools. Thanks to MotoMinded, I was able to track down the clear plastic that I needed for the actual shield. The last item I needed to source to make a complete face shield was a headstrap, and I ended up using a couple of pieces of nylon 550 cord, tied to make a strap that functions just like the waist strap on your backpack. I made a few samples and got them in the hands of some friends who are nurses, and the local hospital’s supply chain manager for a final validation and assessment of fitness for use.

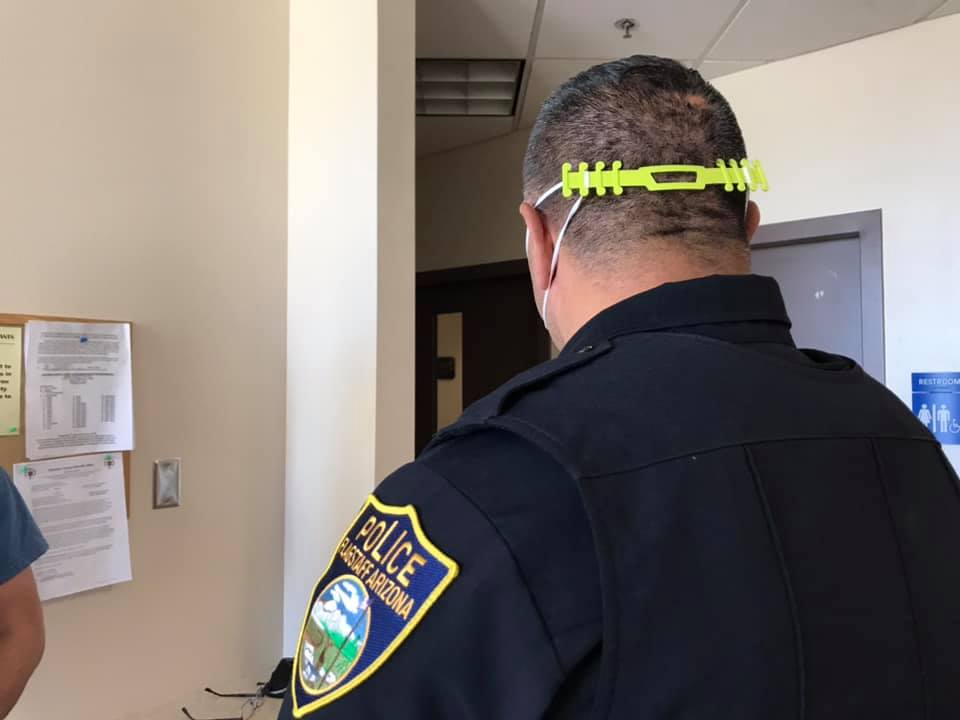

One of the more popular crowdsourced 3D Printed face shield designs is Prusa Research RC3 USA face shield. This design prints relatively quickly and has been optimized using USA standards for things 3-hole punches to make a face shield that’s easily manufactured without special tools. Thanks to MotoMinded, I was able to track down the clear plastic that I needed for the actual shield. The last item I needed to source to make a complete face shield was a headstrap, and I ended up using a couple of pieces of nylon 550 cord, tied to make a strap that functions just like the waist strap on your backpack. I made a few samples and got them in the hands of some friends who are nurses, and the local hospital’s supply chain manager for a final validation and assessment of fitness for use. Other organizations I provided samples to requested different features. The Prusa RC3 face shield design in open at the top, and so some organizations have requested a closed top or a visor – something that crowdsourcing has once again addressed and validated. On the NIH exchange, I found remixes of the RC3 face shield with a visor and with a closed top – exactly what these organizations were looking for. This is what it’s all about – getting the folks who are on the front lines of this fight the tools that they need NOW. Healthcare workers aren’t the only folks who can use additional PPE during this time either.

Other organizations I provided samples to requested different features. The Prusa RC3 face shield design in open at the top, and so some organizations have requested a closed top or a visor – something that crowdsourcing has once again addressed and validated. On the NIH exchange, I found remixes of the RC3 face shield with a visor and with a closed top – exactly what these organizations were looking for. This is what it’s all about – getting the folks who are on the front lines of this fight the tools that they need NOW. Healthcare workers aren’t the only folks who can use additional PPE during this time either.

If making PPE sounds like a something that you want to get involved with, there are a number of ways that you can help out. You don’t have to have a printer to make an impact, as there is so much more to this whole process than just printing parts. Here are a few good things to know:

If making PPE sounds like a something that you want to get involved with, there are a number of ways that you can help out. You don’t have to have a printer to make an impact, as there is so much more to this whole process than just printing parts. Here are a few good things to know: