Lately, supply chain shortages became a part of daily life. For many folks, it started with toilet paper and disinfecting products like Clorox wipes and hand sanitizer. Now, in some areas meat is the unobtanium-du-jour. Who knows what’s next. Yet for healthcare workers and other folks who are on the front lines of the fight against COVID-19, the PPE needed to protect these folks from exposure to the virus has been in seriously short supply for months. Globally.

Despite the lack of N95 masks and isolation gowns, face shields and other PPE essentials, healthcare workers and so many other folks are continuing to go above and beyond their job duties knowing full well that this lack of PPE may cause them to contract the virus. Commercial PPE manufactures are scrambling to make all items that they can, but we as regular citizens have the ability to help make even more PPE to help out the folks on the front lines of this fight. Thanks to crowdsourcing and 3D Printing, folks just like you and me can help keep our healthcare workers and others safe from COVID-19.

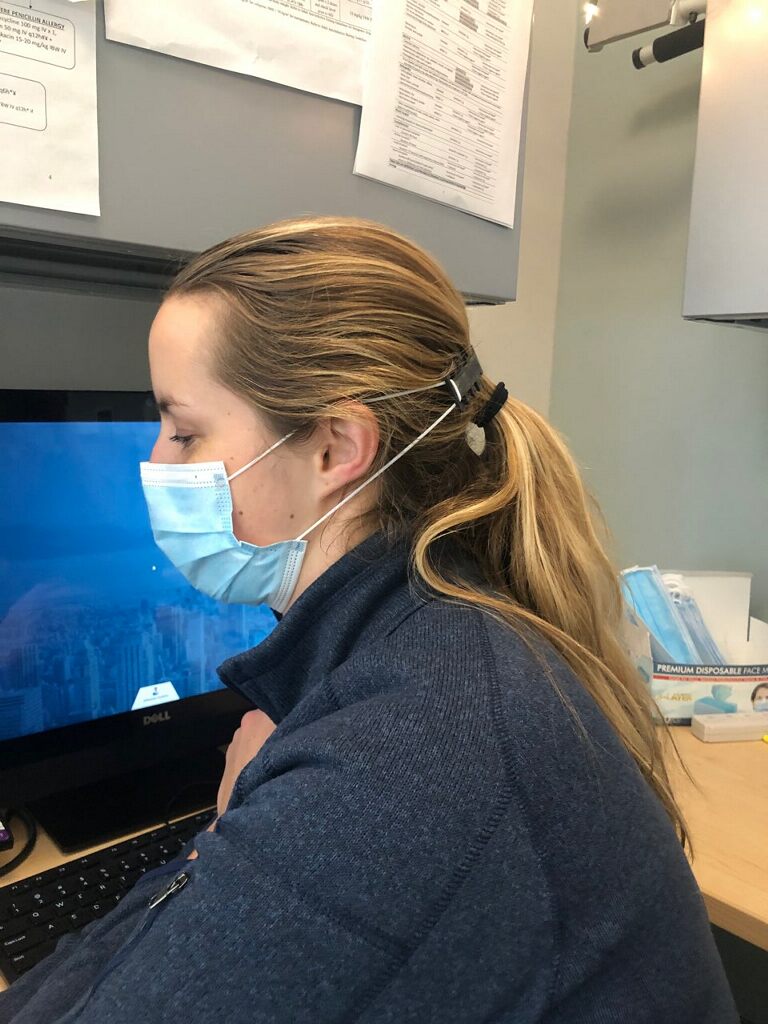

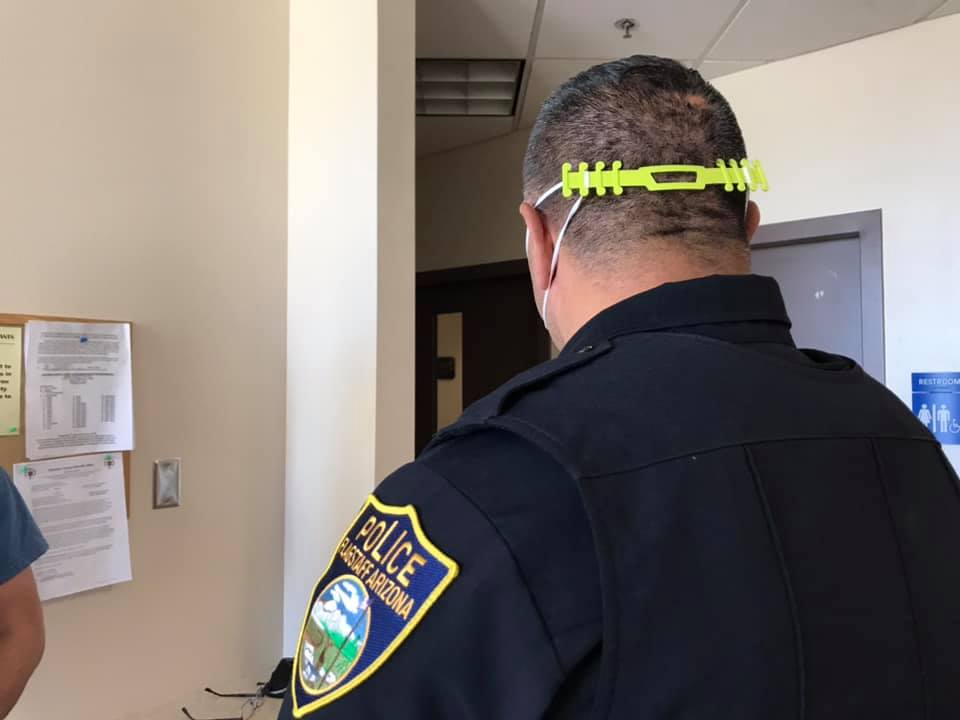

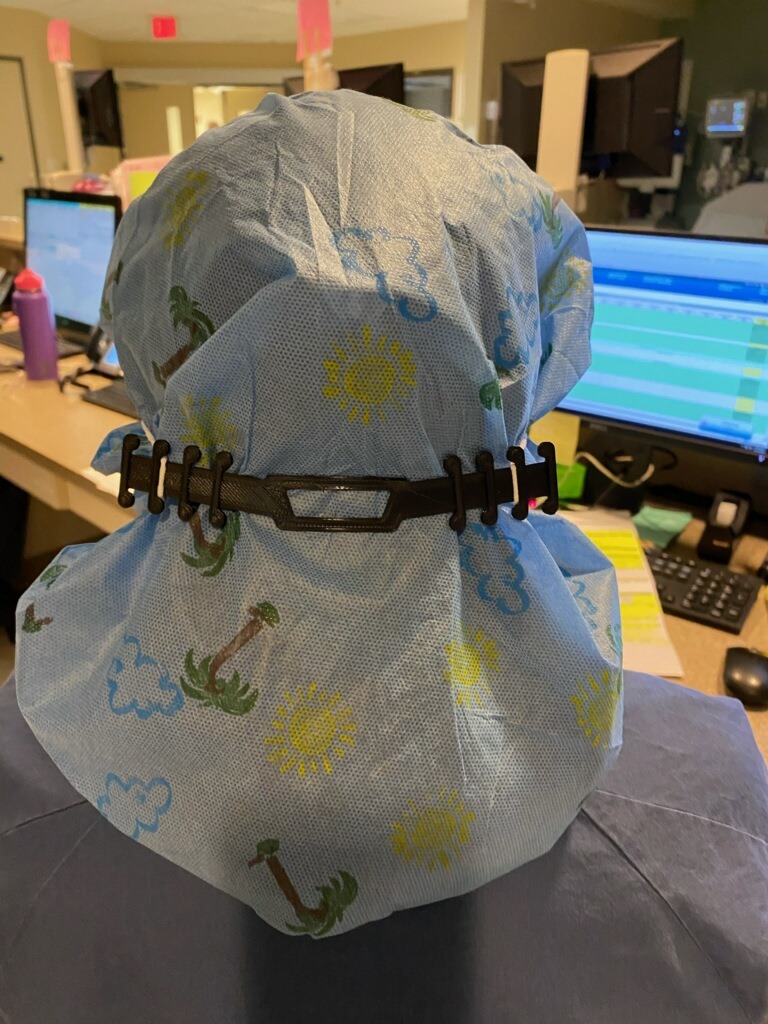

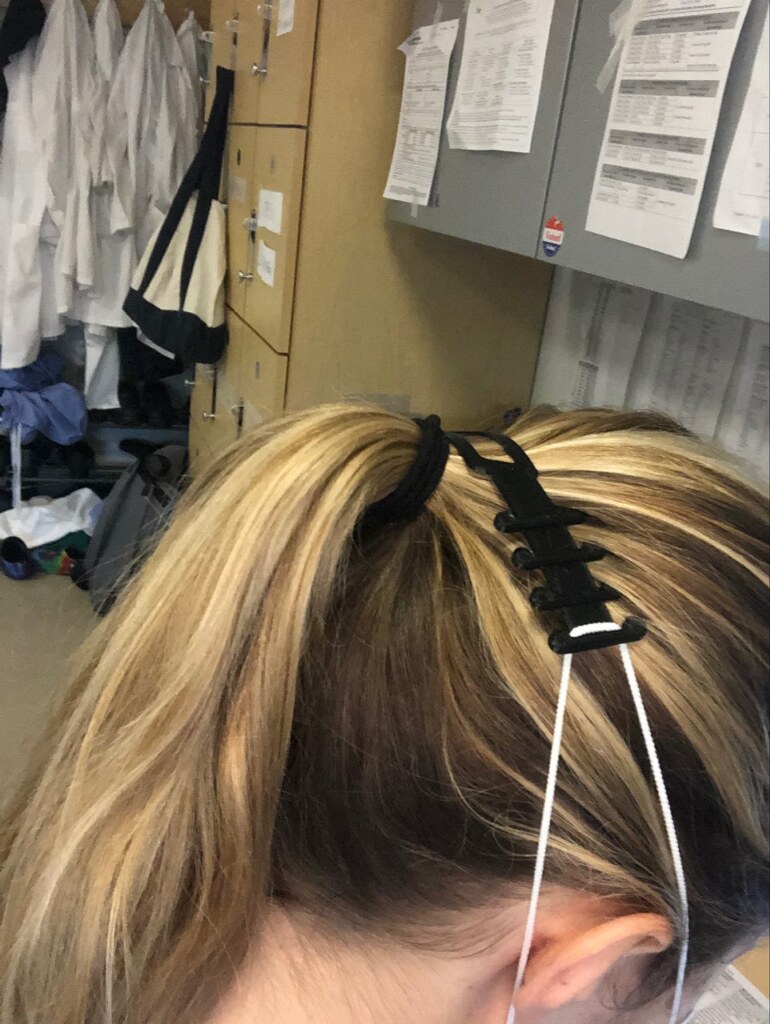

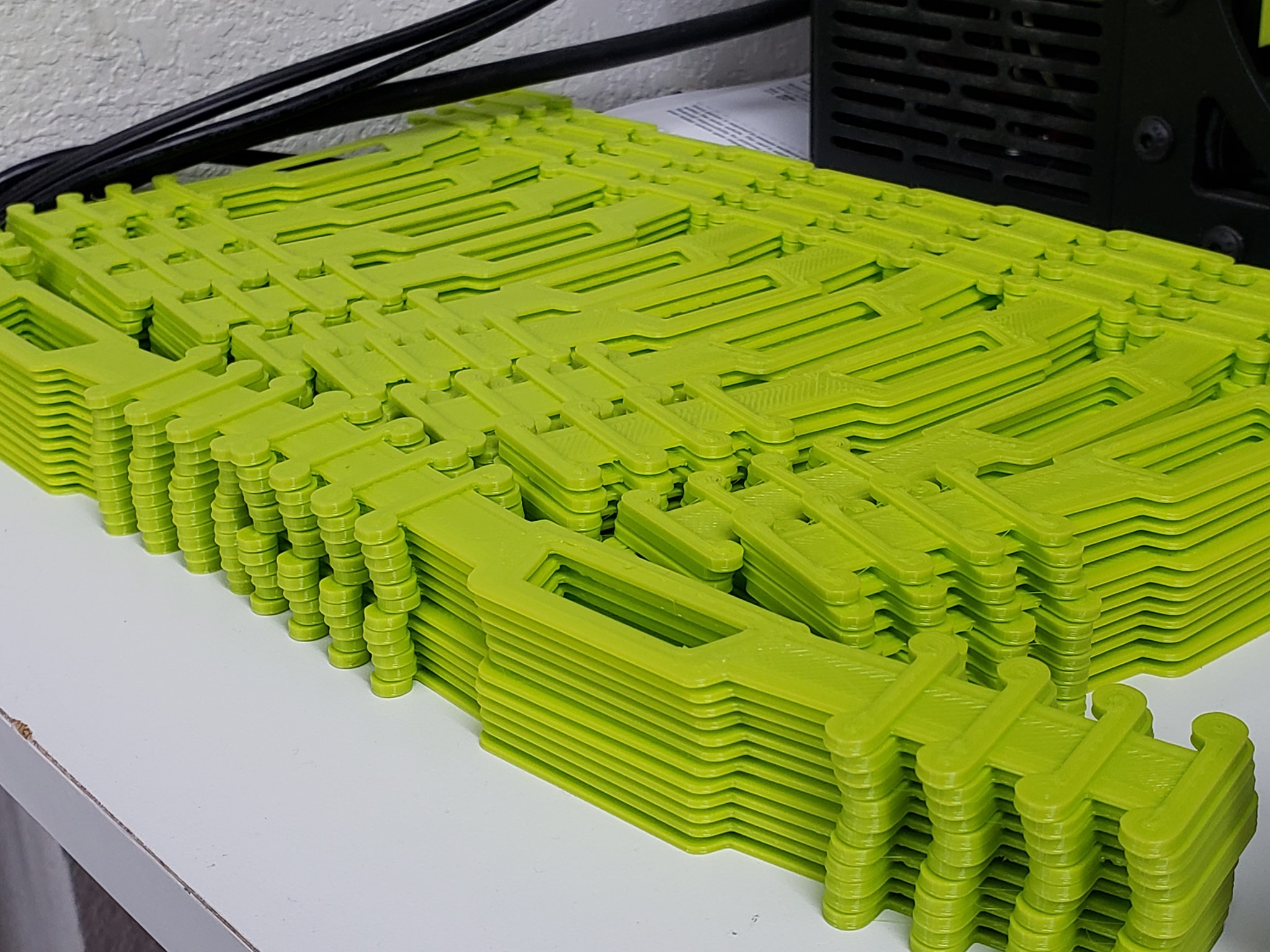

In early April, I came across an article about a Canadian Boy Scout who used his 3D printer to help out his local hospital. As the story goes, the hospital had put out a community-wide request for help as their caregivers were experiencing pain from wearing face masks that hook behind the wearer’s ears for extended periods of time. The boy scout used his 3D Printer to create a simple device that holds the straps from the mask off of the back of the wearer’s ears. He made a bunch and distributed them to his hospital. Problem solved. Reading this inspired me and made me want to know more. Surely if surgical masks were hurting folks in one hospital, they were hurting folks in other hospitals – and so my next move was all but made for me. I sourced the design for this “Ear Saver” from the National Intitute’s of Health (NIH.GOV) 3D print exchange and fired up my own 3D Printers.

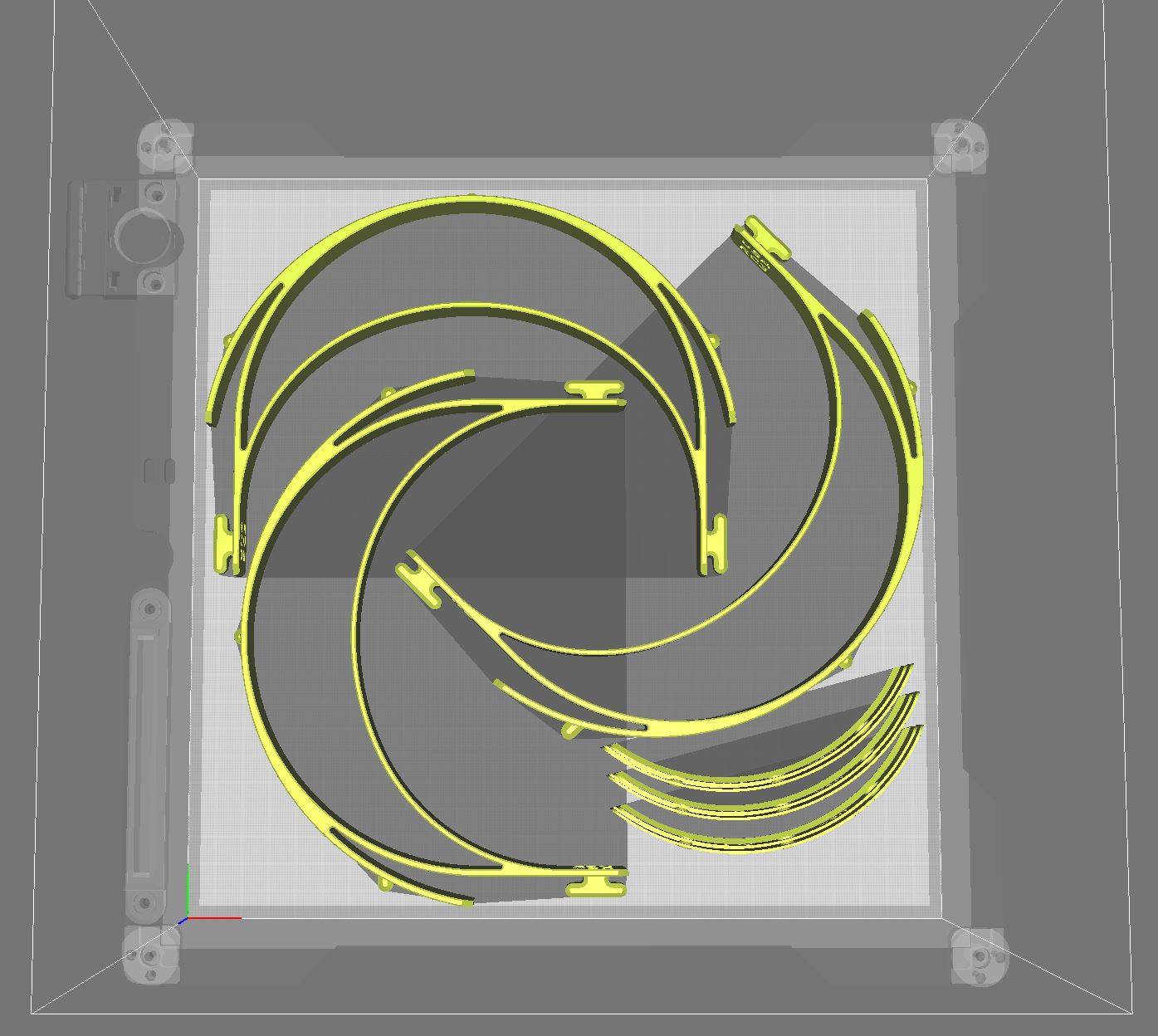

While my first few batches of Ear Savers were printing, I consulted the Googles to get up to speed on how folks all over the world are 3D Printing PPE. In a sentence – what some folks are doing right now to help our healthcare workers and first responders is truly impressive. In a matter of days, folks have spun up operations that are cranking out serious volumes of face shields, masks, and all kinds of other parts that hospitals and healthcare workers need right now. After watching a few videos and reading about some of these operations, I started searching to see if anyone had organized such an effort in Northern Arizona – but I could not find anything. I knew that a local company that makes medical devices and the university were organizing projects internally, but I didn’t see anything underway by regular Joes. So I jumped in and started learning how to make face shields in addition to the ear savers that I was already producing.

Thankfully, a friend of mine in Colorado was a couple weeks ahead of me in his own effort to make face shields – and picking his brain on how to make it happen was invaluable in getting my project off the ground quickly. Normally, my buddy’s company, MotoMinded makes awesome things for dirt bikes and ADV bikes – but they completely pivoted to making face shields when a Colorado non-profit reached out for help. Getting the download on the things that work, things that do not, and all of the other little details was a huge help. You see, you can’t just print out any old headband, stick some kind of clear plastic to it, and use the rubber band from last night’s asparagus to hold the contraption on your head. You have to make sure your PPE is actually going to help the user and not just become a potential source of liability.

Thankfully, a friend of mine in Colorado was a couple weeks ahead of me in his own effort to make face shields – and picking his brain on how to make it happen was invaluable in getting my project off the ground quickly. Normally, my buddy’s company, MotoMinded makes awesome things for dirt bikes and ADV bikes – but they completely pivoted to making face shields when a Colorado non-profit reached out for help. Getting the download on the things that work, things that do not, and all of the other little details was a huge help. You see, you can’t just print out any old headband, stick some kind of clear plastic to it, and use the rubber band from last night’s asparagus to hold the contraption on your head. You have to make sure your PPE is actually going to help the user and not just become a potential source of liability.

To make quality PPE, you need to print with certain filaments, like PETG, that can withstand the steam autoclave sterilization method that hospitals use. Likewise, all of the other components of the face shield have to be able to withstand sterilization so that the item can be re-used. Thankfully, there are a bunch of folks out there who have already conducted this research and they’re happy to share their knowledge. Thanks internet. The global maker community has come together to crowdsource designs, get them validated by healthcare professionals, and then get tons of these supplies in the hands of the folks who need them.

To make quality PPE, you need to print with certain filaments, like PETG, that can withstand the steam autoclave sterilization method that hospitals use. Likewise, all of the other components of the face shield have to be able to withstand sterilization so that the item can be re-used. Thankfully, there are a bunch of folks out there who have already conducted this research and they’re happy to share their knowledge. Thanks internet. The global maker community has come together to crowdsource designs, get them validated by healthcare professionals, and then get tons of these supplies in the hands of the folks who need them.

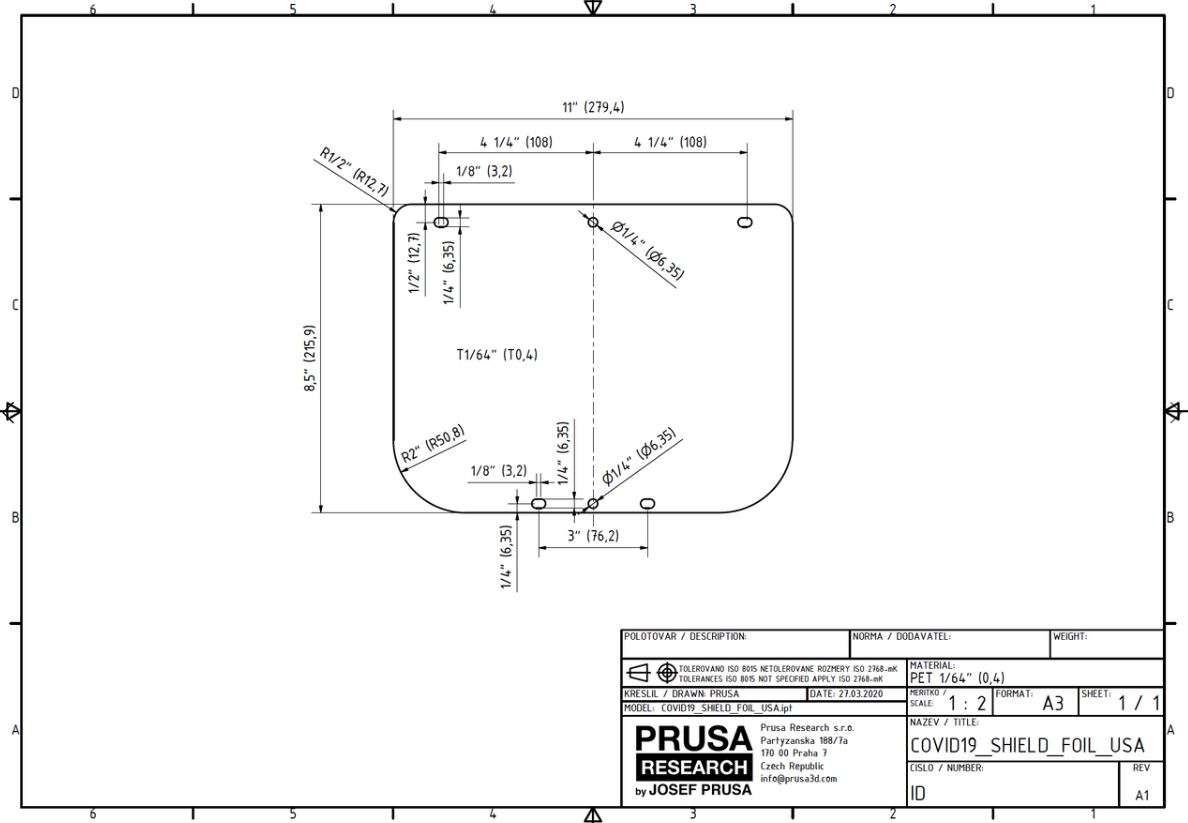

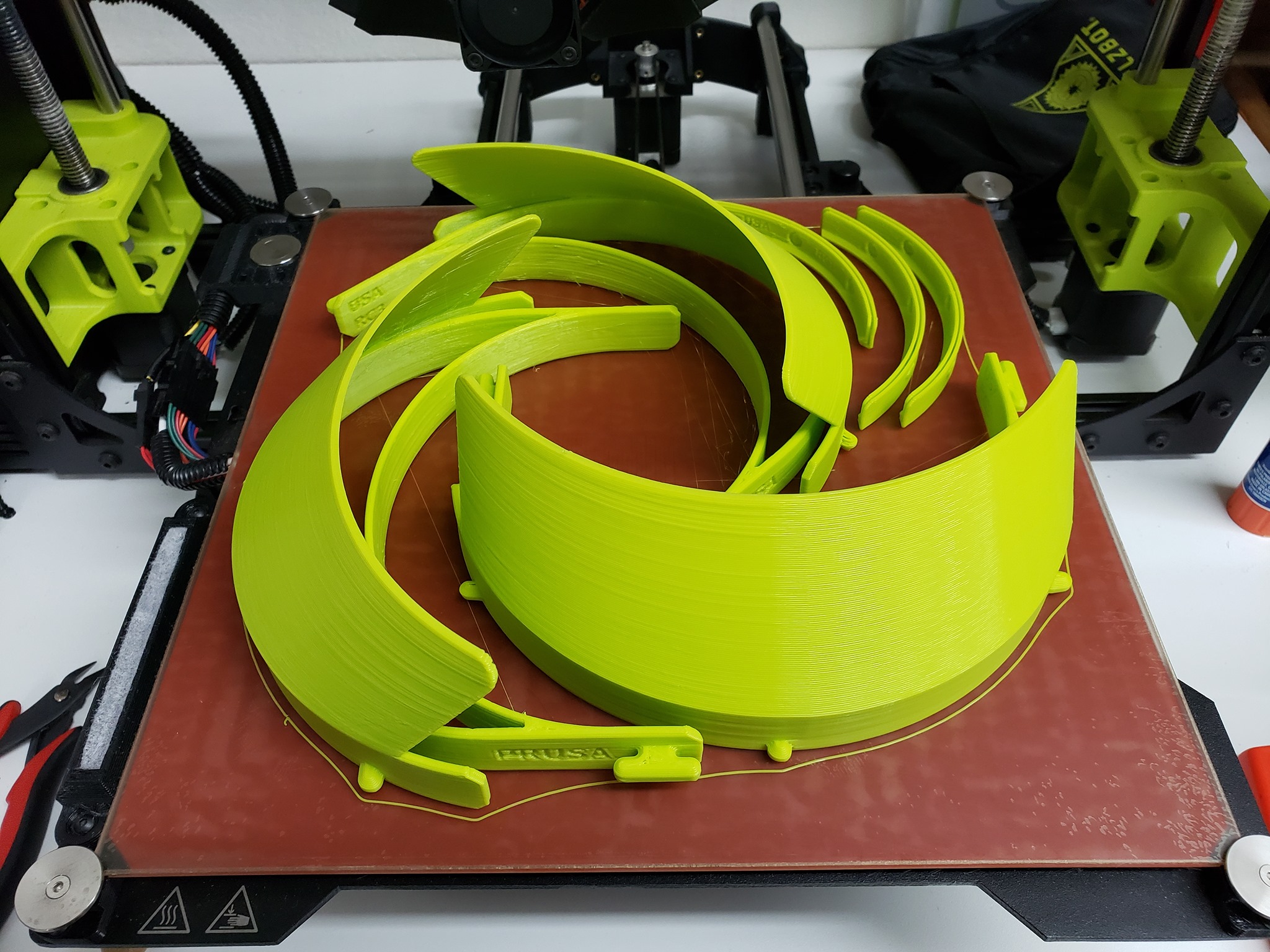

One of the more popular crowdsourced 3D Printed face shield designs is Prusa Research RC3 USA face shield. This design prints relatively quickly and has been optimized using USA standards for things 3-hole punches to make a face shield that’s easily manufactured without special tools. Thanks to MotoMinded, I was able to track down the clear plastic that I needed for the actual shield. The last item I needed to source to make a complete face shield was a headstrap, and I ended up using a couple of pieces of nylon 550 cord, tied to make a strap that functions just like the waist strap on your backpack. I made a few samples and got them in the hands of some friends who are nurses, and the local hospital’s supply chain manager for a final validation and assessment of fitness for use.

One of the more popular crowdsourced 3D Printed face shield designs is Prusa Research RC3 USA face shield. This design prints relatively quickly and has been optimized using USA standards for things 3-hole punches to make a face shield that’s easily manufactured without special tools. Thanks to MotoMinded, I was able to track down the clear plastic that I needed for the actual shield. The last item I needed to source to make a complete face shield was a headstrap, and I ended up using a couple of pieces of nylon 550 cord, tied to make a strap that functions just like the waist strap on your backpack. I made a few samples and got them in the hands of some friends who are nurses, and the local hospital’s supply chain manager for a final validation and assessment of fitness for use.

Other organizations I provided samples to requested different features. The Prusa RC3 face shield design in open at the top, and so some organizations have requested a closed top or a visor – something that crowdsourcing has once again addressed and validated. On the NIH exchange, I found remixes of the RC3 face shield with a visor and with a closed top – exactly what these organizations were looking for. This is what it’s all about – getting the folks who are on the front lines of this fight the tools that they need NOW. Healthcare workers aren’t the only folks who can use additional PPE during this time either.

Other organizations I provided samples to requested different features. The Prusa RC3 face shield design in open at the top, and so some organizations have requested a closed top or a visor – something that crowdsourcing has once again addressed and validated. On the NIH exchange, I found remixes of the RC3 face shield with a visor and with a closed top – exactly what these organizations were looking for. This is what it’s all about – getting the folks who are on the front lines of this fight the tools that they need NOW. Healthcare workers aren’t the only folks who can use additional PPE during this time either.

While I was getting up to speed on my 3D Printed PPE project, American Adventurist staffer Cris Mateski, (@blkwgn) was also busy putting his 3D Printers to work to make Ear Savers. In talking to him I began to fully appreciate just how many different organizations beyond healthcare workers need PPE right now. Cris has been giving his Ear Savers to police, fire, and other public service departments in southern California. Hearing this, I got inspired to dive headlong into this project – why not start shipping face shields and ear savers to folks all across the country in addition to supplying folks who need them here in Northern Arizona? This is a global pandemic afterall.

Today, my new around-the-clock job is 3D Printed PPE manufacture. We’ve donated supplies from California to New York City, and from Tucson, AZ to Missoula, MT. And the requests just keep coming in.

If making PPE sounds like a something that you want to get involved with, there are a number of ways that you can help out. You don’t have to have a printer to make an impact, as there is so much more to this whole process than just printing parts. Here are a few good things to know:

If making PPE sounds like a something that you want to get involved with, there are a number of ways that you can help out. You don’t have to have a printer to make an impact, as there is so much more to this whole process than just printing parts. Here are a few good things to know:

- Get online and get involved. Find out if there are operations in your area that are already printing or manufacturing PPE. If there are, reach out and find out how you can help out. These larger operations certainly need folks to print parts, but many of them need volunteers to sterilize parts, package parts, make other components, or help with logistics – so find out where you can jump in and help out.

- If you’re in a more rural area and there aren’t any organized operations in your area, reach out! Post on social media what you want to accomplish, and see if you can scare up some help. Strong alone – stronger together. Then reach out to your hospitals, Law Enforcement, Fire, City and County Health departments, doctor’s organizations, or anyone else who could need PPE and find out what they need.

- Stick to validated designs wherever you can. The NIH is a great resource for designs for 3D Printed parts that have been “clinically validated.” That last thing you want to do is cause an issue for a healthcare worker or expose yourself to some serious liability. If you are going to do something – do it right and follow the design requirements (like filament type). Yes, there are a ton of potential improvements to the designs that are our there right now, but lets just make the stuff that’s been approved and proven to work.

The bottom line is that if you have the bandwidth to help right now, know that a little effort can go a long way to potentially protecting someone from contracting COVID-19. To learn more about my project, you can check out our Facebook page. The goal is to make as many face shields and ear savers as we can, and get them wherever they need to go, anywhere in the United States. Our healthcare workers are our frontline forces in the fight against this coronavirus as well as any future threat, so anything we can do to help them will make it easier for them to help the folks who are suffering from this virus.

Stay safe, stay healthy, and thanks for reading.

My buddy didn’t make it through the snowbank. With the sound of wet snow sliding and then returning to its resting state of semi-cured concrete, my buddy’s truck came to a stop high-centered on the snowbank. And people were watching. Moments ago, we had assured these onlookers that we knew what we were doing, and that we weren’t some YOLO-seeking idiots out to go further than anyone else had down a road blocked with snowbanks for the ‘Gram. (Full disclosure: My buddy owns land at the end of this road. No road closures or other regulations were violated).

My buddy didn’t make it through the snowbank. With the sound of wet snow sliding and then returning to its resting state of semi-cured concrete, my buddy’s truck came to a stop high-centered on the snowbank. And people were watching. Moments ago, we had assured these onlookers that we knew what we were doing, and that we weren’t some YOLO-seeking idiots out to go further than anyone else had down a road blocked with snowbanks for the ‘Gram. (Full disclosure: My buddy owns land at the end of this road. No road closures or other regulations were violated). With a bit of shoveling and his Maxsas in place, my buddy tried to move his truck forward, but his tires couldn’t grip the non-existent teeth featured on Amazon’s Choice for recovery boards. More shoveling ensued to provide better placement for the Maxsas and less drag on the vehicle. Speedy recovery wasn’t happening, so I took more photos..

With a bit of shoveling and his Maxsas in place, my buddy tried to move his truck forward, but his tires couldn’t grip the non-existent teeth featured on Amazon’s Choice for recovery boards. More shoveling ensued to provide better placement for the Maxsas and less drag on the vehicle. Speedy recovery wasn’t happening, so I took more photos.. While my buddy’s tires are admittedly tired (see what I did there) and not aired down as far as they could be, they were still completely unable to grab any sort of meaningful traction from the Maxsa traction boards. When we placed a pair of MAXTRAX XTREME’s in the snow for both of the rear tires to grab, the difference in performance couldn’t have been more drastic. The truck’s tires grabbed the alloy teeth like they were magnetically attracted to each other and my buddy’s truck was instantly able to move forward onto dry ground and freedom.

While my buddy’s tires are admittedly tired (see what I did there) and not aired down as far as they could be, they were still completely unable to grab any sort of meaningful traction from the Maxsa traction boards. When we placed a pair of MAXTRAX XTREME’s in the snow for both of the rear tires to grab, the difference in performance couldn’t have been more drastic. The truck’s tires grabbed the alloy teeth like they were magnetically attracted to each other and my buddy’s truck was instantly able to move forward onto dry ground and freedom.

We passed all three of our vehicles over this first snowbank and made it all of 60 yards down the road before we had to negotiate our next snowbank. Again, we employed the XTREME’s to help us quickly negotiate successive snowbanks as we continued to make progress down the road. On larger snowbanks and snowdrifts, progress was limited to the length of road we could make with all of our vehicle recovery boards, which provided a great opportunity to compare all of the different recovery boards back to back. To put it bluntly, the difference in performance is night and day.

We passed all three of our vehicles over this first snowbank and made it all of 60 yards down the road before we had to negotiate our next snowbank. Again, we employed the XTREME’s to help us quickly negotiate successive snowbanks as we continued to make progress down the road. On larger snowbanks and snowdrifts, progress was limited to the length of road we could make with all of our vehicle recovery boards, which provided a great opportunity to compare all of the different recovery boards back to back. To put it bluntly, the difference in performance is night and day.

After a full day of MAXTRAX-ing our way through snowbanks, I felt the need to reset my baseline for traction board performance, and so I saved one of the larger snowbanks on our drive out to only use my Mark II’s. With one on each tire, I was able easily climb up and over a large, rutted snowbank. Mark IIs are still great vehicle recovery boards, and after a full day of use, my set looked no worse for wear. The same can’t be said for the Maxsas, which were all showing serious stress-lightening of the plastic. On a scale of 1-10 in super-wet spring snow, the XTREME’s provide traction performance at 10, with Mark II’s a solid 9. We’ll just say that Amazon’s choice may not be the best choice here.

After a full day of MAXTRAX-ing our way through snowbanks, I felt the need to reset my baseline for traction board performance, and so I saved one of the larger snowbanks on our drive out to only use my Mark II’s. With one on each tire, I was able easily climb up and over a large, rutted snowbank. Mark IIs are still great vehicle recovery boards, and after a full day of use, my set looked no worse for wear. The same can’t be said for the Maxsas, which were all showing serious stress-lightening of the plastic. On a scale of 1-10 in super-wet spring snow, the XTREME’s provide traction performance at 10, with Mark II’s a solid 9. We’ll just say that Amazon’s choice may not be the best choice here. With the new XTREME’s proven in the extreme of constant use in the snow, it was time to take them to another extreme, and put them to work in the sand dunes of Southern Nevada in the middle of summer. With triple digit air temps and the sand considerably warmer, both human and machine were put to the test during a multi-day sand dune driving course. In these conditions, each time a vehicle would get stuck the recovery was an absolute exercise in making an accurate stuck assessment and efficient recovery.

With the new XTREME’s proven in the extreme of constant use in the snow, it was time to take them to another extreme, and put them to work in the sand dunes of Southern Nevada in the middle of summer. With triple digit air temps and the sand considerably warmer, both human and machine were put to the test during a multi-day sand dune driving course. In these conditions, each time a vehicle would get stuck the recovery was an absolute exercise in making an accurate stuck assessment and efficient recovery. In the time that I’ve had the XTREME’s, they’ve proven to be exactly what I hoped they would be – a burlier version of the Mark II’s that retain everything that makes earlier versions great. At every chance I’ve had or created for a vehicle recovery, they have performed flawlessly and are no worse for the wear. Since I’m the guy in my group of local friends who has MAXTRAX, I’m constantly supplying them for recovery situations, and it’s great to have the peace of mind that when I’m helping someone out who isn’t dialed in on proper MAXTRAX usage, or is just a little to high-strung at the moment, accidental wheelspin isn’t going to roast my traction boards. Do I still use and carry my Mark IIs? Absolutely. They’re awesome and the ace up my sleeve for when stuck happens to me. Yet, when I’m heading out knowing that I’m going to be the guy providing the MAXTRAX for any recoveries that may occur, I’ll toss in the XTREME’s.

In the time that I’ve had the XTREME’s, they’ve proven to be exactly what I hoped they would be – a burlier version of the Mark II’s that retain everything that makes earlier versions great. At every chance I’ve had or created for a vehicle recovery, they have performed flawlessly and are no worse for the wear. Since I’m the guy in my group of local friends who has MAXTRAX, I’m constantly supplying them for recovery situations, and it’s great to have the peace of mind that when I’m helping someone out who isn’t dialed in on proper MAXTRAX usage, or is just a little to high-strung at the moment, accidental wheelspin isn’t going to roast my traction boards. Do I still use and carry my Mark IIs? Absolutely. They’re awesome and the ace up my sleeve for when stuck happens to me. Yet, when I’m heading out knowing that I’m going to be the guy providing the MAXTRAX for any recoveries that may occur, I’ll toss in the XTREME’s.

If you’re trying to decide between the XTREME’s and Mark II’s, know that you can’t go wrong with either. But, let me offer a few hypothetical questions to help you identify which MAXTRAX are right for you. If you’re the type of person who isn’t getting stuck every time out, or when you do get stuck you’re not prone to using panic throttle, Mark II’s are a great option that will last you a very long time.

If you’re trying to decide between the XTREME’s and Mark II’s, know that you can’t go wrong with either. But, let me offer a few hypothetical questions to help you identify which MAXTRAX are right for you. If you’re the type of person who isn’t getting stuck every time out, or when you do get stuck you’re not prone to using panic throttle, Mark II’s are a great option that will last you a very long time.

The additional performance of the XTREME’s comes with additional costs in several areas. A single XTREME weighs a couple pounds more than a Mark II (10 pounds vs. 8), and a set of XTREME’s doesn’t stack as tightly as a set of Mark II’s (4x Mark II’s are ~ 4 inches tall, where 4x XTREME’s are ~ 5.5 inches tall). But the biggest pain point of all is the cost – a pair of them cost $500 whereas a pair of Mark II’s costs $300. Yet for the folks who truly need the performance of an XTREME, these factors are hardly a consideration when weighed against the benefits.

The additional performance of the XTREME’s comes with additional costs in several areas. A single XTREME weighs a couple pounds more than a Mark II (10 pounds vs. 8), and a set of XTREME’s doesn’t stack as tightly as a set of Mark II’s (4x Mark II’s are ~ 4 inches tall, where 4x XTREME’s are ~ 5.5 inches tall). But the biggest pain point of all is the cost – a pair of them cost $500 whereas a pair of Mark II’s costs $300. Yet for the folks who truly need the performance of an XTREME, these factors are hardly a consideration when weighed against the benefits. I’m sure by now someone is getting ready to fire off a smart comment to the effect of “but I can buy X sets of <insert cheap brand vehicle recovery board here> for the price of one set of MAXTRAX” Well that may be true – but everyone who makes that argument always seems to assume that they’re going to have data coverage and instant Amazon Prime delivery wherever in the world they are when they break their first set of cheapo traction boards trying to get unstuck or get home. I know Amazon delivers in cool Sprinter vans, but I sure haven’t seen many off-road. My suggestion would be to do it right the first time and get a product that isn’t going to let you down when it counts.

I’m sure by now someone is getting ready to fire off a smart comment to the effect of “but I can buy X sets of <insert cheap brand vehicle recovery board here> for the price of one set of MAXTRAX” Well that may be true – but everyone who makes that argument always seems to assume that they’re going to have data coverage and instant Amazon Prime delivery wherever in the world they are when they break their first set of cheapo traction boards trying to get unstuck or get home. I know Amazon delivers in cool Sprinter vans, but I sure haven’t seen many off-road. My suggestion would be to do it right the first time and get a product that isn’t going to let you down when it counts. In summary, you can’t go wrong with MAXTRAX. Yeah, you’re going to pay for them up front, but the first time you use them in a recovery and get to fully appreciate what a powerful tool they are you’ll find yourself saying “worth it” when your mobility is restored. In my experience, the difference between cheap alternatives and the genuine article has been night and day, and there’s plenty of good videos on the internet that corroborate my experience. I certainly don’t want to roll the dice on my family’s well being just to save a couple bucks. You can’t put a price on the peace of mind that comes from knowing you have quality tools with you to see the world and then see your friends and family back home safely.

In summary, you can’t go wrong with MAXTRAX. Yeah, you’re going to pay for them up front, but the first time you use them in a recovery and get to fully appreciate what a powerful tool they are you’ll find yourself saying “worth it” when your mobility is restored. In my experience, the difference between cheap alternatives and the genuine article has been night and day, and there’s plenty of good videos on the internet that corroborate my experience. I certainly don’t want to roll the dice on my family’s well being just to save a couple bucks. You can’t put a price on the peace of mind that comes from knowing you have quality tools with you to see the world and then see your friends and family back home safely.