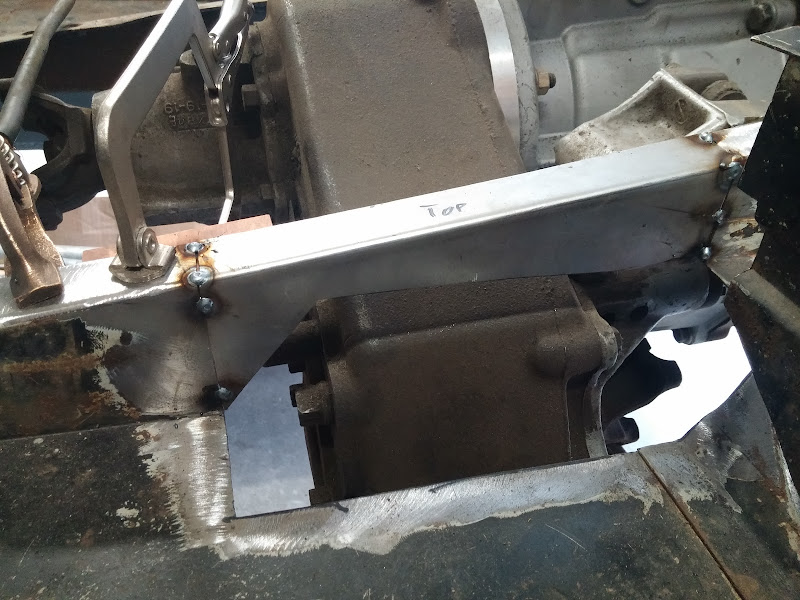

Hmm, looks like someone shot holes in the bottom of my truck, I'm picturing the scene from the Top Gear Africa special where the guide shoots the floors of the cars to drain out water after a stream crossing

That one looks about 9mm, there have got to be a half dozen .22 sized holes. All in the floor, my work today is going to be patching all of them

No, that jack isn't holding up the body, just acting as a stabilizer.

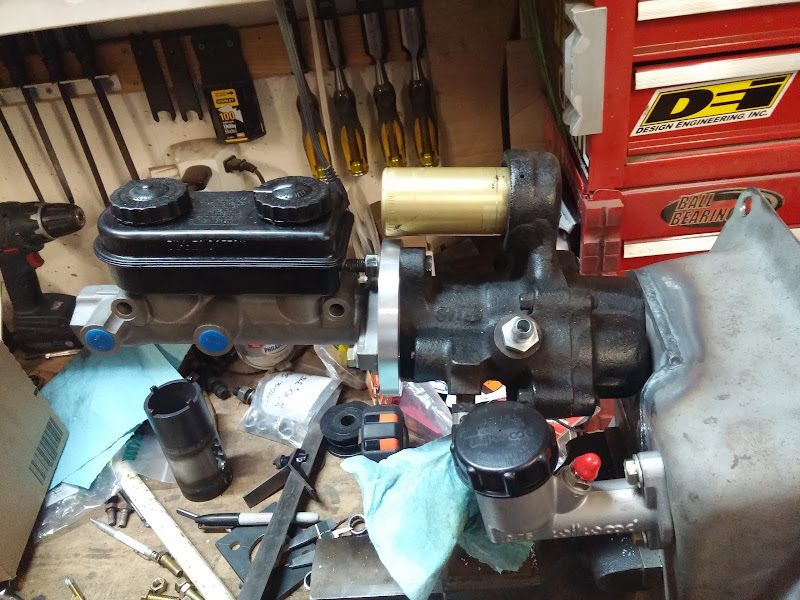

The last few weekends have been spent getting the floors cleaned up, holes welded and generally prepped as well as I can for paint. Lots of time with these, as well as some air tools. You can never have too many grinders.

You can see the 'before' condition above, here's the after (with more bullet holes):

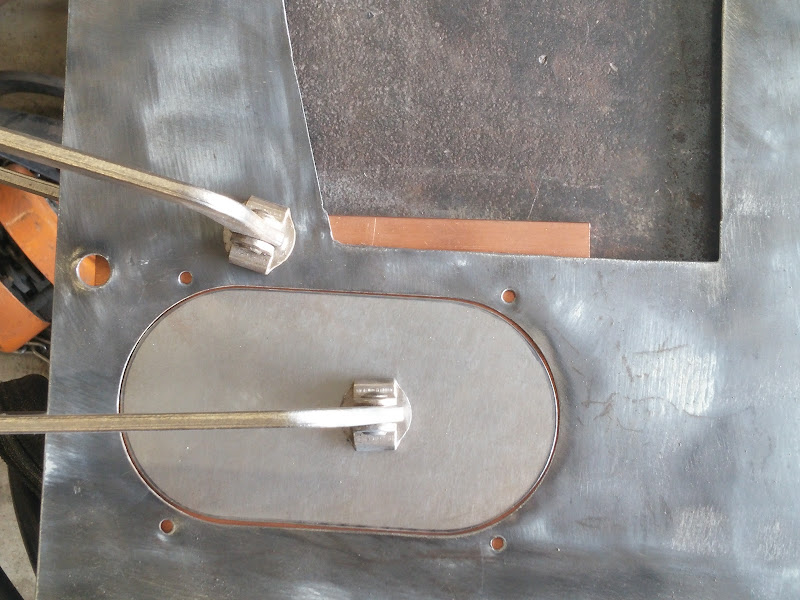

I made up a little tool to make welding up holes easier, its a switchable magnet that holds a 1/4" thick piece of copper against the panel. Worked out really well, it is strong enough I could stick it under the bed and do my welding from above. I'm doing all of this solo so this worked way easier than one of those welding spoons you have to hold.

Same process under the bed, then a few coats of Eastwood Rust Encapsulator

And the end result of all this work, 2 coats of Lizardskin Sound Control sprayed under the bed.

I used a generic undercoating (schutz) gun, my buddy gave it to me after he sprayed bedliner with it. Took a little adjusting to get the air pressure and nozzle settings right but it worked out pretty well. The Lizardskin stuff is nice to work with, cleans up with water and doesn't really have a smell to it. Painting under the truck sucks, I was glad I bought a tyvek bunny suit with a hood to keep the spatter mostly off of me.

I'll re-mask and spray the floorboards this week, then the body goes back on the frame this weekend.

That one looks about 9mm, there have got to be a half dozen .22 sized holes. All in the floor, my work today is going to be patching all of them

No, that jack isn't holding up the body, just acting as a stabilizer.

The last few weekends have been spent getting the floors cleaned up, holes welded and generally prepped as well as I can for paint. Lots of time with these, as well as some air tools. You can never have too many grinders.

You can see the 'before' condition above, here's the after (with more bullet holes):

I made up a little tool to make welding up holes easier, its a switchable magnet that holds a 1/4" thick piece of copper against the panel. Worked out really well, it is strong enough I could stick it under the bed and do my welding from above. I'm doing all of this solo so this worked way easier than one of those welding spoons you have to hold.

Same process under the bed, then a few coats of Eastwood Rust Encapsulator

And the end result of all this work, 2 coats of Lizardskin Sound Control sprayed under the bed.

I used a generic undercoating (schutz) gun, my buddy gave it to me after he sprayed bedliner with it. Took a little adjusting to get the air pressure and nozzle settings right but it worked out pretty well. The Lizardskin stuff is nice to work with, cleans up with water and doesn't really have a smell to it. Painting under the truck sucks, I was glad I bought a tyvek bunny suit with a hood to keep the spatter mostly off of me.

I'll re-mask and spray the floorboards this week, then the body goes back on the frame this weekend.