Tonight I was able to get the front axle cycled up to what I think will be full bump + a bit. At this point the steering tie rod will be damn near getting into the frame. There seems to be pretty decent clearance in the wheel well, I’ll throw a fender on tomorrow to see how much trimming its going to take but it looks alright so far.

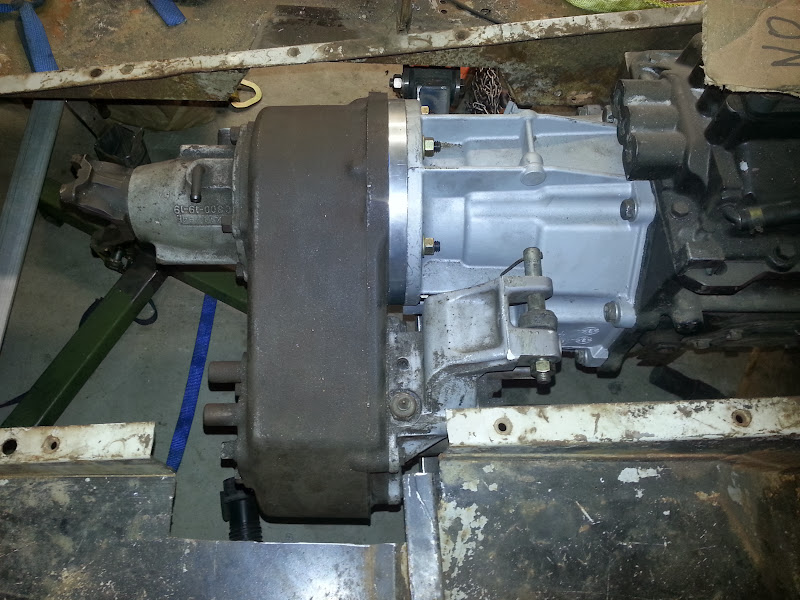

The new motor mount is doing its job, plenty of clearance

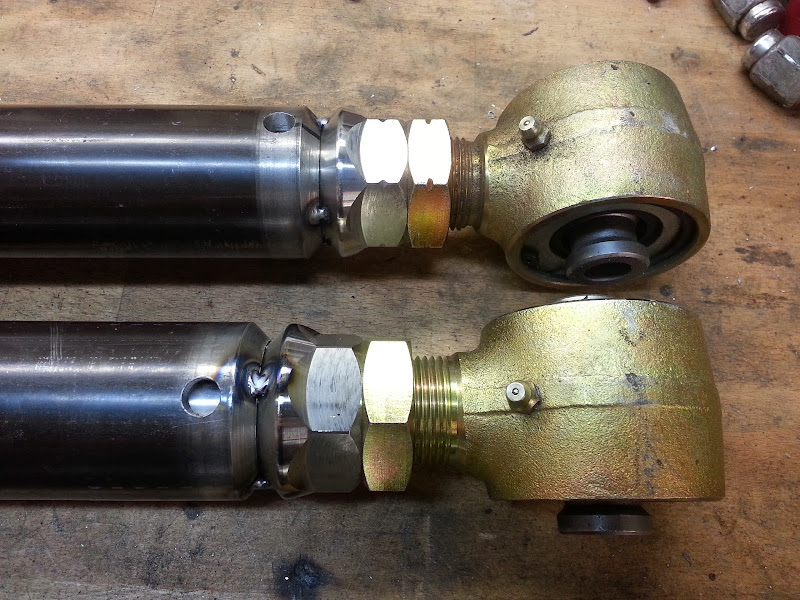

I need to see what this looks like with the axle articulated, but it looks like the coilover has enough room.

The front of the wheel well will get trimmed as needed, cant check it yet because the bumper is in the way. Here’s how it looks turned hard driver

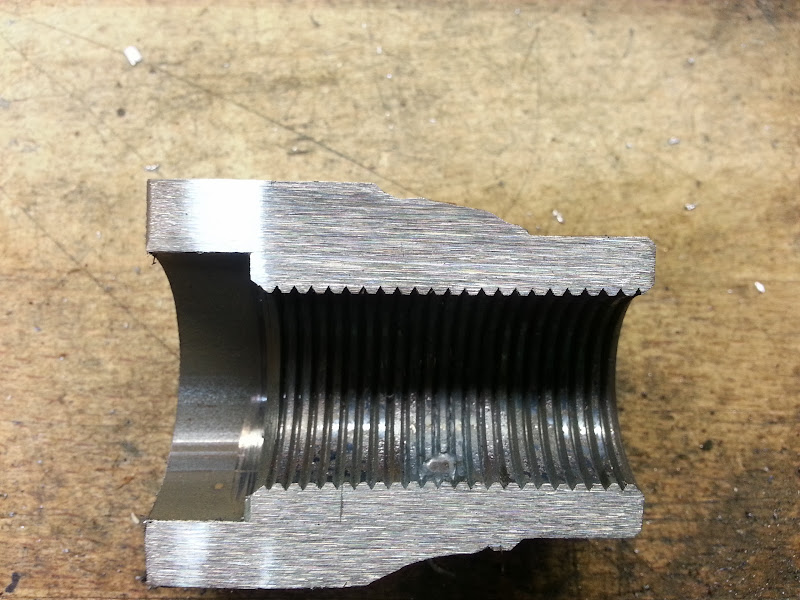

I’m going to try to get the lower link tubing bent to get rid of this issue

If anyone knows what sort of bender it takes to bend 2” OD, ¼” wall tube let me know. I’m assuming the typical JD2 bender won’t be very happy?

The new motor mount is doing its job, plenty of clearance

I need to see what this looks like with the axle articulated, but it looks like the coilover has enough room.

The front of the wheel well will get trimmed as needed, cant check it yet because the bumper is in the way. Here’s how it looks turned hard driver

I’m going to try to get the lower link tubing bent to get rid of this issue

If anyone knows what sort of bender it takes to bend 2” OD, ¼” wall tube let me know. I’m assuming the typical JD2 bender won’t be very happy?