Taking advantage of a day with less conference calls I made some more progress today.

First up an inventory of what's being added:

Fishbone Offroad 52" Light Bar Bracket

Mictuning M1s 52" Light Bar

Mictuning 193 Light Pods

Why Mictuning? I've run Mictuning products of one sort or another on my last 4 vehicles and I've never had an issue out of any of them. Are they as bright or well manufactured as Baja Designs or Rigid? Probably not. I considered going with Rigid this time around as I've had a chance to examine some of their products and really like their build quality. At the end of the day I can't justify spending that much money on a product that, realistically, will only be utilized probably 10% of the time I'm in the vehicle. On top of that my vehicle sees lengthy stays in airport parking garages. If I return to find these lights missing I won't be nearly as upset as I would be if Rigids had been stolen. These lights put out enough light to do what I want to do and I guess that's good enough.

First up I mounted the Fishbone Offroad light bar bracket using the Jeep's stock hardware. I had read online of people having to purchase longer hardware to get these mounted but I had no problems. Once they were tightened down I put the Mictuning lightbar in place and routed the wire down under the cowel around the wipers. Next up I mounted the pods and ran the wires in similar fashion. The light pods came with amber running lights so they're a three wire setup vs the two wire of the light bar.

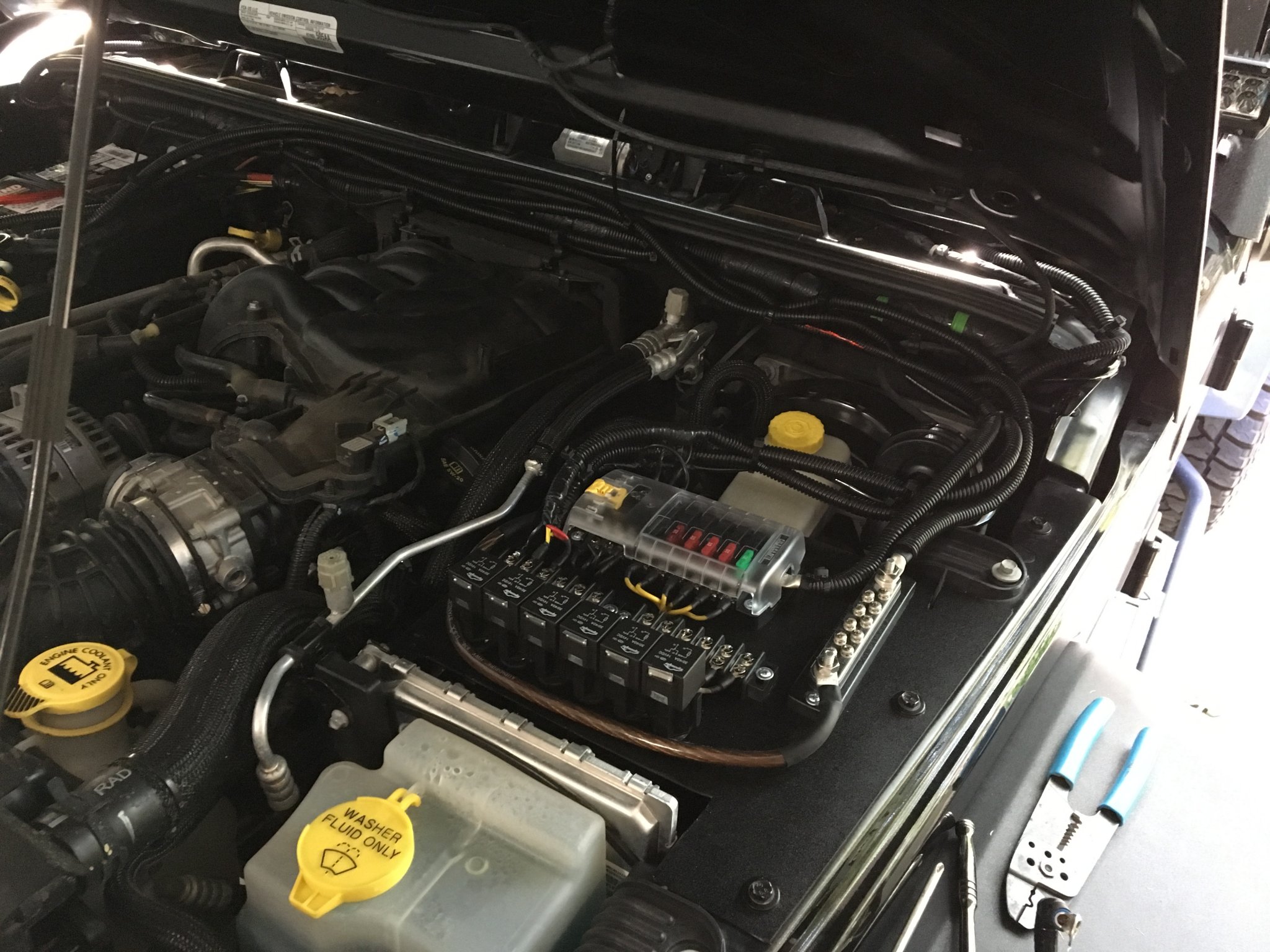

I spliced to the provided harness and used heat shrink and loom to close everything up before routing it through the engine bay. I followed the factory wire loom that runs across the back of the engine bay and then landed the wiring on my new power distribution panel. I pulled the ground wire out of the loom before the 2 positive wires so that it would line up with the ground connection on the Blue Sea fuse panel. Everything was terminated using ring connectors that were crimped and heat shrunk.

Up until this point I hadn't tied my panel into the Jeep's electrical system yet, I'd only physically mounted it in place. Amazon showed up with the 4 gauge wire I'd ordered so it was time to fix that. Is 4 gauge overkill? Oh yeah, but does it give me piece of mind when adding circuits later? Sure does.

I routed the power wire through the 100A breaker I mounted on top of the OEM fuse panel and ran it, along with the ground wire, across the back of the engine bay. I don't think this space can handle any more cabling.

On the side of the Jeep where my panel is mounted I landed the power wire onto the positive side of the Blue Sea fuse panel and the ground to the Blue Sea common rail ground terminal. I then ran another short piece of 4 gauge wire from the other side of the ground terminal to the ground side of the Blue Sea fuse panel. I reset the 100A breaker and things were live!

As I was running wiring I tried to be cognizant of future upgrades or repairs. For example all of the wiring running to my panel has a small bit of slack in it and comes in on the right side of the panel. If you pull the three factory bolts that are holding it in place the entire panel could be set on the fender to provide access to the ABS module underneath. The only place I didn't accomplish this was on the battery side. The connection from the battery side of the 100A fuse to the positive terminal runs directly over the top of the battery. When it comes time to replace the battery years from now I'll need to pull the connection to do so. I don't really consider this a bad thing though since disconnecting all power to my panel when swapping the battery is probably a good safety procedure. Beyond that running the connection they way I did provided the least amount of strain on this cable and allowed me to secure it in the firmest way possible.

Years ago I had a truck with a fairly high wattage aftermarket stereo setup. I had a 0 gauge wire coming off the positive terminal to a 300 amp fuse. The connector on the fuse side failed one day allowing the cable to come loose. Because of how the cable was routed there was tension on the cable and it didn't just fall out of the connector, but instead pulled out swiftly and began striking the metal of the hood and fender. I was able to throw a t shirt over top of it to finally get it to stop bouncing around and arcing off anything it could ground to. Ever since I've been paranoid of connections to the battery that could cause that to happen again. The straight connection I've run here along with the heat shrink, wire loom and mechanical connection provided by the zip ties should prevent that from ever happening.

Overall very happen with the way things are turning out thus far. Full on #lightsbeforelockers!

This Mictuning light bar is supposed to be more aerodynamically shaped to prevent the whistling and acoustical resonance other bars create. So far with the soft top down I can drive at interstate speeds with just a little increased noise, but no whistling or resonance. With the top up there's a small whistle around 70 mph, but I haven't done anything to adjust the angle of the bar yet. Supposedly tilting it down a few degrees will route the air up over the vehicle in a more natural way and eliminate the whistle completely. I'll have to tackle that this weekend when I've got time to adjust / test.

On the side of the Jeep where my panel is mounted I landed the power wire onto the positive side of the Blue Sea fuse panel and the ground to the Blue Sea common rail ground terminal. I then ran another short piece of 4 gauge wire from the other side of the ground terminal to the ground side of the Blue Sea fuse panel. I reset the 100A breaker and things were live!

On the side of the Jeep where my panel is mounted I landed the power wire onto the positive side of the Blue Sea fuse panel and the ground to the Blue Sea common rail ground terminal. I then ran another short piece of 4 gauge wire from the other side of the ground terminal to the ground side of the Blue Sea fuse panel. I reset the 100A breaker and things were live!