You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Java's F450 'Rough Road' RV

- Thread starter java230

- Start date

Looks like east side of the Cascades in Washington's Alpine Lakes Wilderness southwest of Leavenworth, WA.

java230

Adventurist

@Al Swope Hes correct, This is "The Enchantments" in the alpine lakes wilderness. Boat loads more pics here if you want.... https://www.flickr.com/photos/115773715@N06/Looks like east side of the Cascades in Washington's Alpine Lakes Wilderness southwest of Leavenworth, WA.

java230

Adventurist

The falls are really cool!

They were, very chilly

But yes, the water just flows downhill from lake to lake, its pretty.

WashingtonTaco

Adventurist

I'm sleeping in your camper next year for Skifari!!!

java230

Adventurist

Speaking of which, we need to pan a route!!I'm sleeping in your camper next year for Skifari!!!

java230

Adventurist

OK guys opinion time.... Its Fall, I need to figure tires out.

Singles are not in the budget at the moment. So options are Spend good $$ on Toyo M608's to match the rear for the fonts. (~$832)

Buy cheap Chinese tires for the fronts. (~$382)

Or step up to Chinese 245's all around. (~$1350)

So opinions, is the step up to a 245 worth it? 1" taller, 3.4% larger rolling diameter is not going to drop much highway RPM's, 1.5" wider may give slightly more traction (and more wander in the snow/slush?)

Tires for reference for anyone who cares....

Toyo

/tiregallery/3347_new/23.jpg)

Milestar Tire

/tiregallery/12218/_5.jpg)

Singles are not in the budget at the moment. So options are Spend good $$ on Toyo M608's to match the rear for the fonts. (~$832)

Buy cheap Chinese tires for the fronts. (~$382)

Or step up to Chinese 245's all around. (~$1350)

So opinions, is the step up to a 245 worth it? 1" taller, 3.4% larger rolling diameter is not going to drop much highway RPM's, 1.5" wider may give slightly more traction (and more wander in the snow/slush?)

Tires for reference for anyone who cares....

Toyo

/tiregallery/3347_new/23.jpg)

Milestar Tire

/tiregallery/12218/_5.jpg)

My opinion is, do you really want to risk your rig on Chinese tires, that may or may not have any problems or go with a known good tire brand that is likely to never give you any problems?

I just went through this with my Miata. I decided on going with a top performance tire versus a unproven Chinese tire. Asking the same type of question, it was pointed out, did I want to risk a failure when driving hard through a corner on a mountain road? It came down to risk versus reward. Depending on how long you run the Toyo's, it's possible to sell them if you decide to upgrade for likely the difference in cost between the two or at least close enough to make the deciding factor mute.

I just went through this with my Miata. I decided on going with a top performance tire versus a unproven Chinese tire. Asking the same type of question, it was pointed out, did I want to risk a failure when driving hard through a corner on a mountain road? It came down to risk versus reward. Depending on how long you run the Toyo's, it's possible to sell them if you decide to upgrade for likely the difference in cost between the two or at least close enough to make the deciding factor mute.

java230

Adventurist

Very true, I am in the fence though as these tires have pretty good reviews.... But it's true your getting a much mkre known commodity with the ToyoMy opinion is, do you really want to risk your rig on Chinese tires, that may or may not have any problems or go with a known good tire brand that is likely to never give you any problems?

I just went through this with my Miata. I decided on going with a top performance tire versus a unproven Chinese tire. Asking the same type of question, it was pointed out, did I want to risk a failure when driving hard through a corner on a mountain road? It came down to risk versus reward. Depending on how long you run the Toyo's, it's possible to sell them if you decide to upgrade for likely the difference in cost between the two or at least close enough to make the deciding factor mute.

WashingtonTaco

Adventurist

Id stay with the Toyo, roll them for 12-18 months then upgrade to singles.

java230

Adventurist

It's $800+ for two God damn tires!!! But yeah.. . I am thinking that's the thing to do. Will probably be a couple years before singles.Id stay with the Toyo, roll them for 12-18 months then upgrade to singles.

WashingtonTaco

Adventurist

It's $800+ for two God damn tires!!! But yeah.. . I am thinking that's the thing to do. Will probably be a couple years before singles.

You want to be a big truck player!

java230

Adventurist

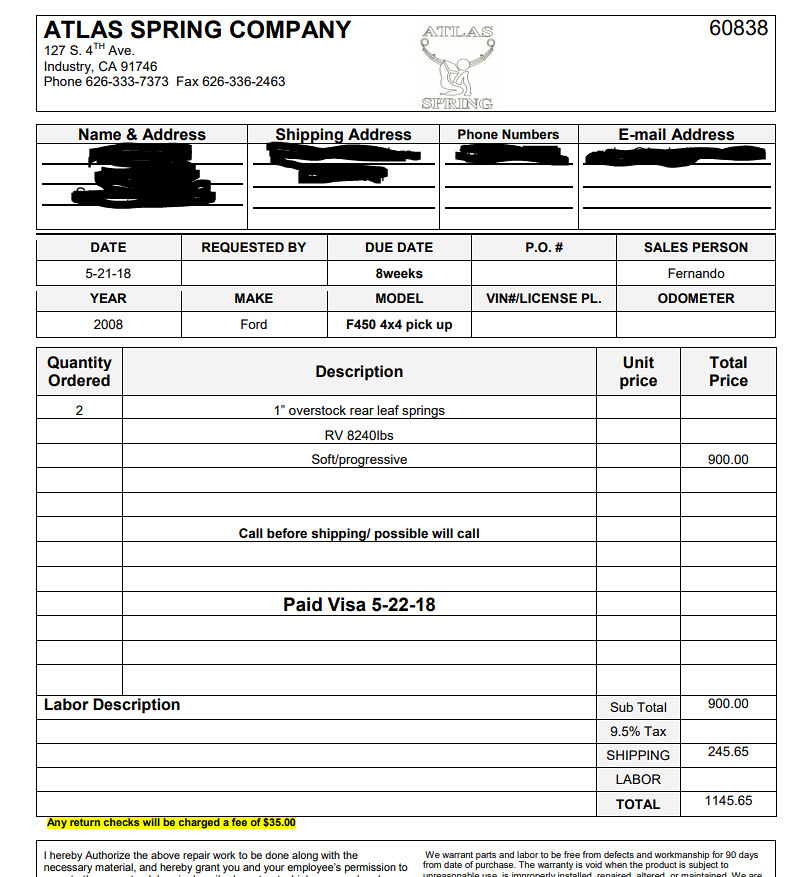

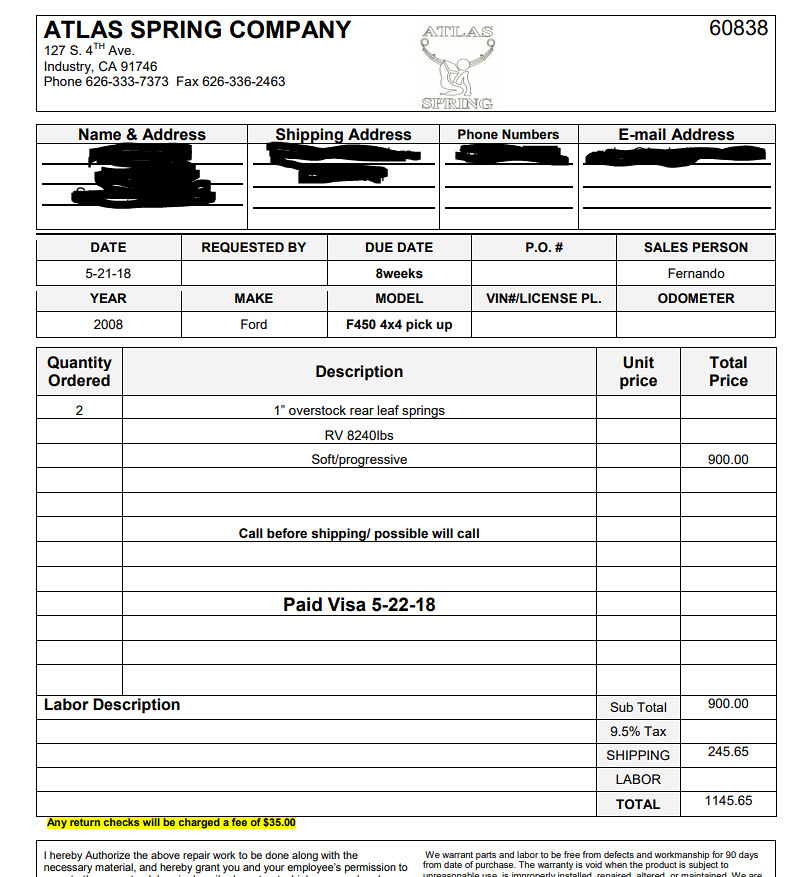

Well I am rapidly losing faith in Atlas Spring Company.

Springs are installed, ended up being able to ream the bushing out to fit the OE bolts (they were the wrong bolt diameter, and not the same OD as the OE bushing so we could not just press those in). Correct length this time.

Now the fun, I took a measurement before I dropped the truck off at the shop. ~37.5" to the wheel well in the rear.

Note the patch of plants, just to show I am in nearly the same spot.

And After.... 36.5" Thats an inch SHORTER not 1" taller than stock!! bags are at 10 psi, I ran 70 previously with the OE springs, just enough to keep then above the overloads or it squeaked like crazy.

And here is my order, clearly give the weight, and 1" over stock. I emailed after the first set were wrong verifying that was rear end only, just to try to mitigate any issues with the new set.

Springs are installed, ended up being able to ream the bushing out to fit the OE bolts (they were the wrong bolt diameter, and not the same OD as the OE bushing so we could not just press those in). Correct length this time.

Now the fun, I took a measurement before I dropped the truck off at the shop. ~37.5" to the wheel well in the rear.

Note the patch of plants, just to show I am in nearly the same spot.

And After.... 36.5" Thats an inch SHORTER not 1" taller than stock!! bags are at 10 psi, I ran 70 previously with the OE springs, just enough to keep then above the overloads or it squeaked like crazy.

And here is my order, clearly give the weight, and 1" over stock. I emailed after the first set were wrong verifying that was rear end only, just to try to mitigate any issues with the new set.

java230

Adventurist

Ive got them re-assembled. That was a fun weekend in the gravel driveway. Big truck stuff is heavy.

Here is what I ended up doing....

Take these two pieces out of the stock pack. The anti wrap leak and the spacer block.

Buy new center pins, cut them down because you can only get 3/4x3/4 heads locally. Ford used 3/4x3/8 ish

Jack up truck from the frame. Remind yourself to use a bottle jack next time..... Floor jacks don't roll on gravel. The license plate panel is not so pretty anymore.... Truck fell off jack.

Plan was to undo U bolts, roll axle forward, drop center pin out, reassemble with extra parts. Well remember this truck has an LSD? Yeah can roll one side forward.... So get out plywood, and a second floor jack, add some ratchet straps, and you can barely move the axle enough (after disconnecting sway bar).

OK, center pin out, WTF why does new one not fit?! Oh Atlas used a smaller one... WHY?! Head would flop in the centering hole in the axle.... Anyway. Now I have to drill out the entire spring pack to the larger center pin..... That was fun and my drill hates me.

Pack with extra bits together.

Now the Ubolts are too short again. Did I mention I just got new ones for this pack?? (at $15 each...) No more pictures, but new Ubolts got made. bolts were tightened, not need to find a torque wrench that goes too 300 ft lbs... They are about as tight as my electric rattle gun will go. Which I had to drive on block and dig a hole under each spring pack to use.... anyway. Frustrated by this ordeal, but truck is derivable now, and ~3/4" higher than it was with the stock springs and airbags, with no air in the bags. I have not even test driven it I was so tired and pissed off. Need to beat the license plate panel out still too.

Here is what I ended up doing....

Take these two pieces out of the stock pack. The anti wrap leak and the spacer block.

Buy new center pins, cut them down because you can only get 3/4x3/4 heads locally. Ford used 3/4x3/8 ish

Jack up truck from the frame. Remind yourself to use a bottle jack next time..... Floor jacks don't roll on gravel. The license plate panel is not so pretty anymore.... Truck fell off jack.

Plan was to undo U bolts, roll axle forward, drop center pin out, reassemble with extra parts. Well remember this truck has an LSD? Yeah can roll one side forward.... So get out plywood, and a second floor jack, add some ratchet straps, and you can barely move the axle enough (after disconnecting sway bar).

OK, center pin out, WTF why does new one not fit?! Oh Atlas used a smaller one... WHY?! Head would flop in the centering hole in the axle.... Anyway. Now I have to drill out the entire spring pack to the larger center pin..... That was fun and my drill hates me.

Pack with extra bits together.

Now the Ubolts are too short again. Did I mention I just got new ones for this pack?? (at $15 each...) No more pictures, but new Ubolts got made. bolts were tightened, not need to find a torque wrench that goes too 300 ft lbs... They are about as tight as my electric rattle gun will go. Which I had to drive on block and dig a hole under each spring pack to use.... anyway. Frustrated by this ordeal, but truck is derivable now, and ~3/4" higher than it was with the stock springs and airbags, with no air in the bags. I have not even test driven it I was so tired and pissed off. Need to beat the license plate panel out still too.

java230

Adventurist

Another weekend in the truck, sure makes a nice cozy cabin!

Did some climbing, hiking and enjoyed the PNW.

On the way home Truck threw a CEL..... P0703, Torque Converter/Brake Switch B Circuit Malfunction, oh joy. Some googling says it may just be the pressure switch behind the master cyl, brake lights still work. Fingers crossed that is the issue. Part is ordered to replace it.

Did some climbing, hiking and enjoyed the PNW.

On the way home Truck threw a CEL..... P0703, Torque Converter/Brake Switch B Circuit Malfunction, oh joy. Some googling says it may just be the pressure switch behind the master cyl, brake lights still work. Fingers crossed that is the issue. Part is ordered to replace it.

java230

Adventurist

Swapped the brake switch out under the master cyl. I guess its a known issues as they sell a "kit" for it. Bleeding the switch was the hardest part. CEL for the bake switch has stayed off.

Took the truck up to deception pass again, nice spot.

Climbed some routes on Mt Erie, new ones we have never done. Finally had to use my bail out carabiner, climbed up a bolted route and found no anchors! I didn't have enough rope to go any higher, possibly could have topped out, but no idea if there was a trail down. Was able to down climb to a bolt (I was up above it by a couple cams) and bail off the route.

The rock that claimed my biner

And next little project, swap the maxxfan out. This one had one too many bumpy roads it seems. It had broken a little tab that kept the top from over traveling, but it seems the hinge blew out too. Luckily Maxxfans warranty is awesome! They asked my serial number and shipped me a new unit.

Four screws and done, need to hook up the electrical still.

Took the truck up to deception pass again, nice spot.

Climbed some routes on Mt Erie, new ones we have never done. Finally had to use my bail out carabiner, climbed up a bolted route and found no anchors! I didn't have enough rope to go any higher, possibly could have topped out, but no idea if there was a trail down. Was able to down climb to a bolt (I was up above it by a couple cams) and bail off the route.

The rock that claimed my biner

And next little project, swap the maxxfan out. This one had one too many bumpy roads it seems. It had broken a little tab that kept the top from over traveling, but it seems the hinge blew out too. Luckily Maxxfans warranty is awesome! They asked my serial number and shipped me a new unit.

Four screws and done, need to hook up the electrical still.