This is an inside look at the I4WDTA. My goal here is to provide some level of transparency for an organization I believe in. To that end, I’d like to provide you with a glimpse inside their Testing for Certification process and the extremely diverse knowledge, skills, and aptitudes required to be successful. There were eight Candidate Trainers and a large number of I4WDTA staff present whom I will refer to here as Cadre during this 2021 event.

The beginnings of the Association

The I4WDTA was founded by off road legend Bill Burke of Bill Burke’s 4-Wheeling America, an internationally recognized trainer and recovery expert who teaches back country driving techniques, winching and extrication methods, vehicle preparation and maintenance, land navigation and woods skills through classes and private training. He’s also a permitted outfitter and guide through the US Forest Service and Bureau of Land Management. Over the years, Bill has served as a consultant for OEM’s like Land Rover, Toyota, and most recently with Rivian.

A US Army veteran, he also represented the USA during the 1991 Camel Trophy in Africa. His professional resume beyond the I4WDTA is far too lengthy to cover here, but on a personal note Bill also tells some seriously hilarious stories if you’re lucky enough to ever share a campfire with him and his dog Henry.

“The Association began as an idea in 2002, a gathering of like minded off-pavement 4WD driver trainers from around the world who wanted to help establish a high level of educational and ethical standards. Our goal was eventual acceptance by civilian, government, industrial and automotive segments as the top 4WD educators in the world, as vetted by third-party and peer review processes. Many invitations were sent, not all were returned. The first Charter meeting in 2004 had an impressive attendance with several renowned trainers ready to work on the SOP and organization standards. I may be the Founder, but the Association has become larger than life with active committees and a Board of Directors. I could not be happier, or more humbled, to see this growth and the members taking ownership of this Association today!”

– Bill Burke

The President of the I4WDTA today is Chris Cole. Born and raised in rural South Africa, he has extensive personal expedition travel experience with all manner of 4WD vehicles, and his academic qualifications including a graduate degree in Adult Education from Cornell University. Chris is also a Special Forces veteran of the South West African Territorial Forces which benefits his government customers being trained to operate with limited resources in varying terrain conditions and high stress situations. This expertise also covers his industrial customers focused on safe, practical operation for workers on and off the grid in different weather conditions.

Additionally, Chris has some serious chops when it comes to engineering, machining, and manufacturing. His latest brainchild is the Safe-Xtract® Vehicle Recovery System which was recently selected by the 1st Special Forces Regiment to be the training standard within the US Army’s SF Groups and is currently fielded and being trained there at the team level. He is particularly well qualified to lead the Association, and his quick wit and sense of humor are well known along with the legendary hospitality shown by him and his wife Anne.

“Today almost all vehicle manufacturers are producing highly capable “adventure” vehicles. Combine this with the SxS market and the explosive growth in the “overlanding” market, and we are seeing a huge expansion of people and vehicles going into recreational areas. All these new folk can greatly benefit from being trained to drive safely on our trails without causing environmental destruction nor hurting themselves or their vehicles. This is where the I4WDTA and our Certified Trainers come in”.

– Chris Cole

Taken together as a team, Bill and Chris offer an incredible amount of insight and experience that is unmatched in the off-road industry today. From driving to engineering to machining and metallurgy, every topic or question fielded by them is painstakingly addressed. These gifted Master Trainers deliver knowledge in such an effective manner that even the most leisurely learner is quickly brought up to speed. They’ll also happily take anyone in the industry to task if they’re full of bull, which I respect.

Based in New Mexico, today the Association is comprised of Certified Trainers with business experience in motorsports, independent guide services, and off-road training. Some members are also automotive design consultants and engineers while others work in the 4WD industry as after-market vehicle equipment manufacturers and specialty vehicle builders.

The unifying goal among this international group is the promotion of safe and responsible 4WD recreation. This is achieved through a rigorous standards-based curriculum and training development program. This one-of-a-kind program seamlessly integrates Tread Lightly! principles with the latest developments in OEM and aftermarket vehicle technology, recovery techniques, and OHV equipment.

I4WDTA Certified Trainers have demonstrated both the professional knowledge and training standards needed to become certified by enduring and passing the most stringent written and practical examinations in the off-road industry. The I4WDTA is the only 4WD Training Association of its kind in the world today that requires members to pass detailed examinations in order to become a Certified 4WD Trainer.

With current members on five continents actively performing 4WD driver and recovery training in every climate on Earth, it’s an undeniable fact that there is nothing else like it today. Maybe that’s why OEM’s like Ford and Rivian are taking notice by encouraging their personnel to engage with the Association.

How do YOU become a Certified Trainer?

No, you can’t simply buy your way into the Association. And this is not “Training for Certification”. Quite a few people confuse that important detail and assume that they will receive the training here or extra instruction that they will need to pass the final exams. The TESTING FOR CERTIFICATION is the only pathway to membership in the Association, a week-long test where success is earned. You will be challenged physically, mentally, and emotionally at a TFC.

My advice? Consider leaving your ego at home, and bring some humility and a willingness to be evaluated with brutal honesty. Bring a thick skin. Start preparing NOW. Read everything you can find that’s 4WD related. Drive everything you can in every environment possible. Manual transmission too. Get stuck and learn how to extract yourself and others. Because anyone who says they’ve “never been stuck” is a damn liar.

If you are out of shape, work on it now. Because you will be outside, in rough terrain, on your feet while spotting, rigging layouts, and working with your hands each day. You will be working with HiLift jacks, Pull Pals and other tools as the situation dictates. Vehicle recovery is hard, physical work.

When you think you’re ready, you can submit an application to attend the next available Testing for Certification. Full details on prerequisites and the complete TFC application process can be found at this link HERE.

What happens at a Testing for Certification (TFC) event?

During my own TFC in Arizona circa 2015, I arrived confident. After all, I’d been wheeling all over the western US for over 20 years and blah blah blah. I’d even been to the University of YouTube. Going into it, I honestly felt like I had a solid foundation.

During my TFC we were evaluated on knowledge, problem solving, didactic presentation and practical exercises. In the classroom and during Cadre led scenario driven events, my own knowledge gaps, misconceptions and flaws were painfully revealed. I endured raised eyebrows and knowing looks from Chris and Bill as well as the other Cadre. They would huddle daily and speak in hushed tones about how my group was performing, comparing notes on our progress and deficiencies. We needed that thick skin I mentioned earlier because we were on the struggle bus.

When they handed me the final written exam, much to my dismay I noted several hundred fill in the blank, essay style questions. This was no multiple choice cake walk like I’d hoped for. We were then given a four hours to complete the final while simultaneously awaiting our turn to be called out individually for the selection board style interview. Other than the northern Arizona mud, that may have been the least fun part of my TFC experience.

When it was all over, I was relieved to have survived this week long process, to have at least made it through to Testing Day 5 without being run off. I was all smiles when Bill and Chris affixed their stately signatures to my certificate making me an I4WDTA Certified Trainer. It was a happy yet humbling moment for sure, especially considering the energy expended in pursuit of this goal.

The TFC begins in the classroom at the Cole Learning Center

Today, Candidates are able to camp near the classroom at the Cole Learning Center, and an excellent food truck was on site the entire week providing three meals a day for both Candidates and Cadre alike. Arriving early and camping on site during the TFC provides many intangible benefits, and enables a higher level bond among the Candidates right out of the gate which becomes a force multiplier later on in the process.

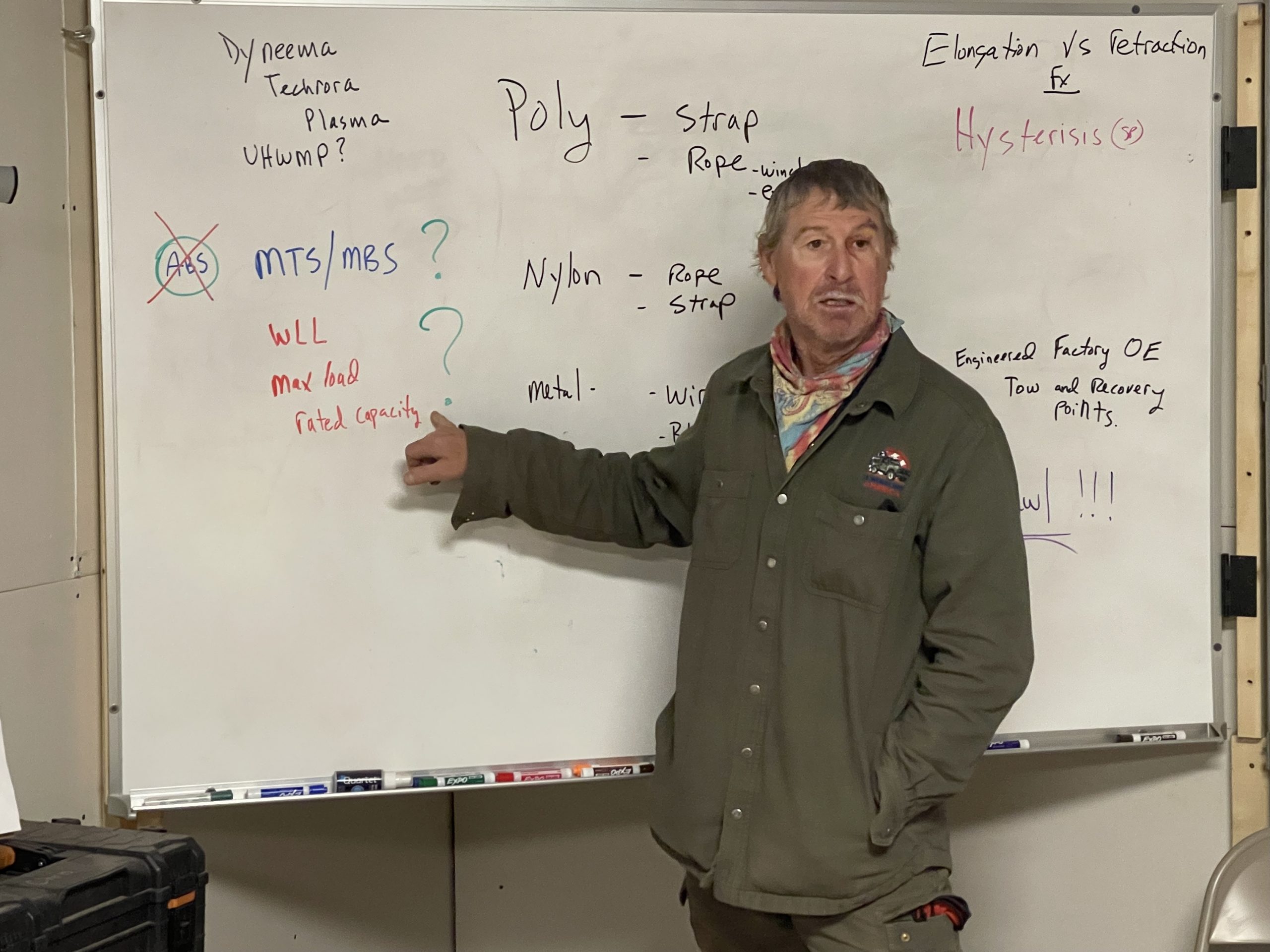

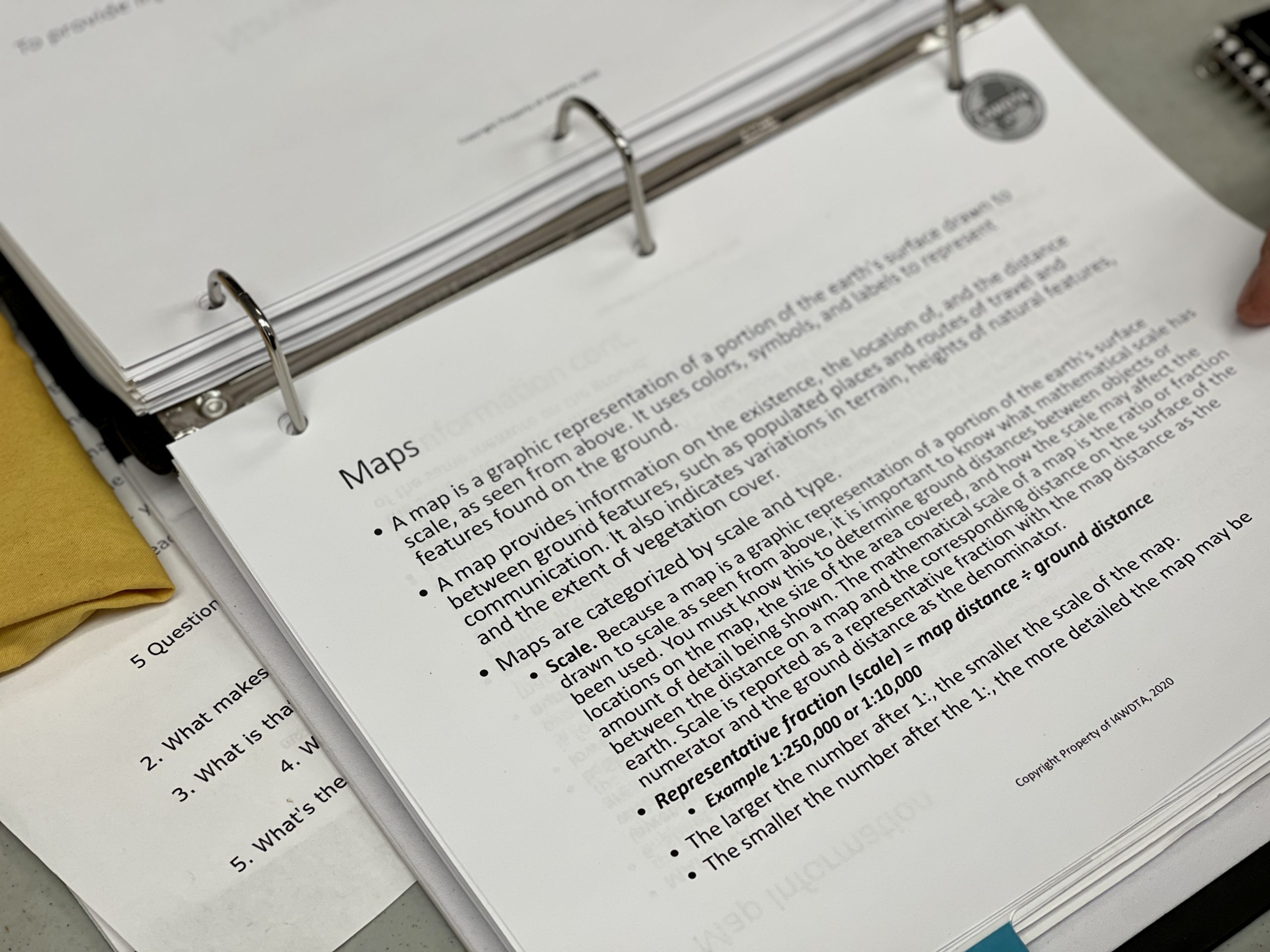

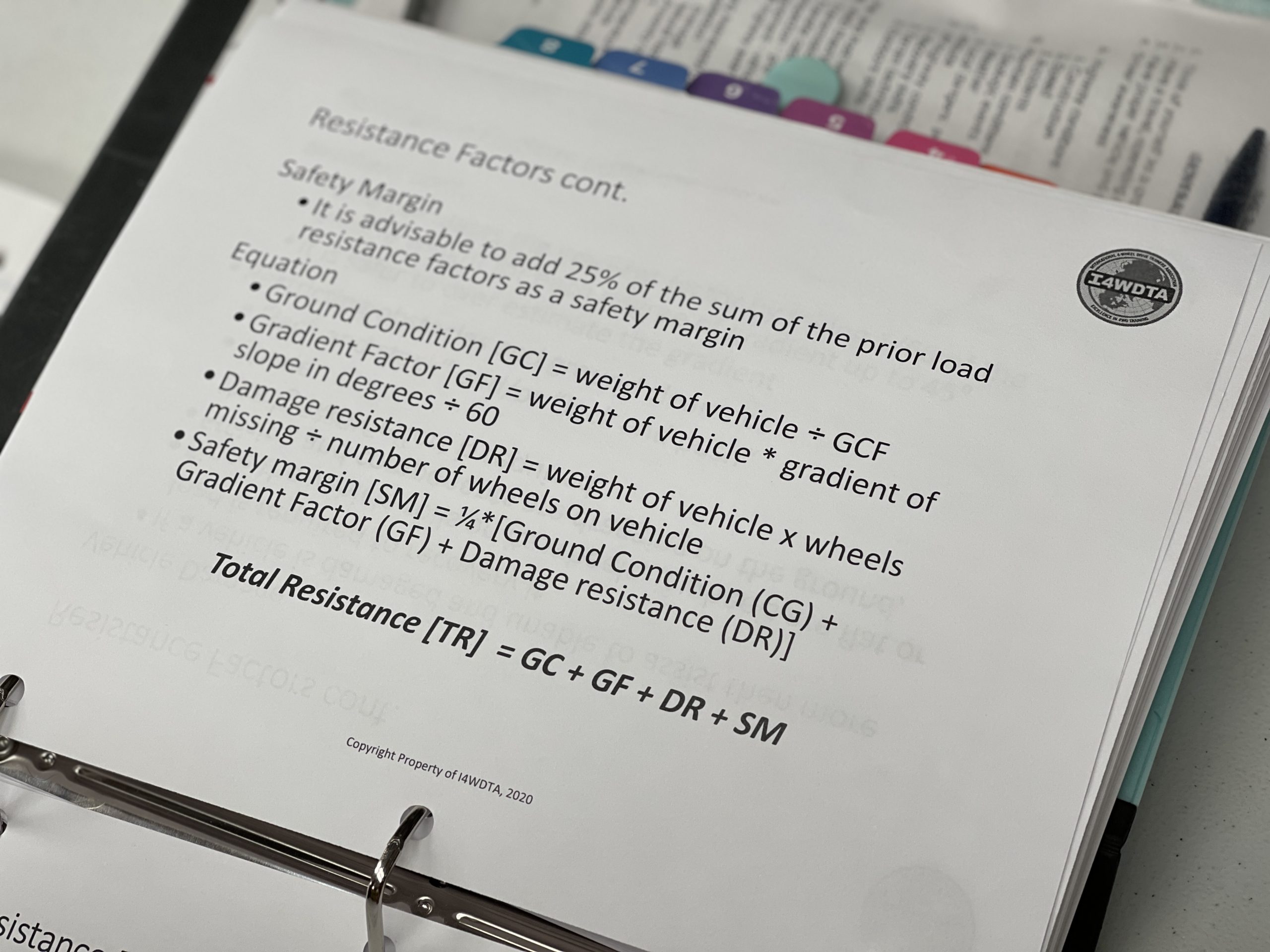

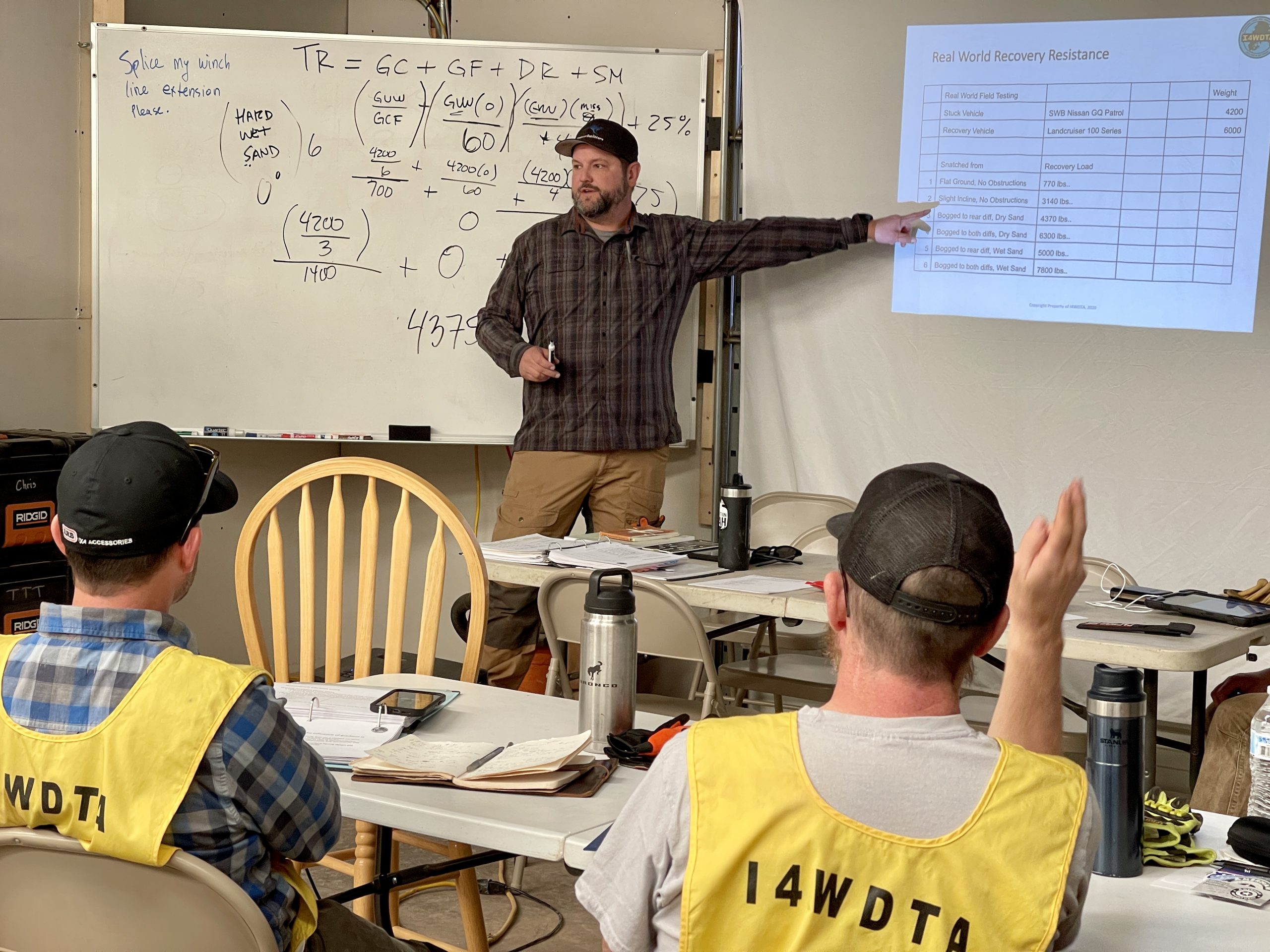

The testing starts in the classroom on Day 1, but after that most of the time is spent testing and teaching outside in the training areas, rain or shine. Topics range from basic to advanced 4WD systems knowledge, trail repair, problem solving ability, navigation, ethics, environmental awareness, and presentation skills to include the conduct of practical exercises.

The days are long at the TFC.

Candidates work from daylight till dark and are expected not only to pass any given quiz, and there are many of them, but to also demonstrate their ability to transfer knowledge and skills by teaching others. The mastery of group dynamics and the ability to work well within small teams is equally as important as an individual’s teaching prowess. A big ego, attitude, or defective moral compass will get you down checked quick by the training Cadre here.

The TFC is much more than classroom work.

Most of the time is spent outdoors at the TFC. Conducted at an altitude of about 5,000 feet, the desert environment in New Mexico provides it’s own set of challenges that must be dealt with. The physical and mental effort required by each Candidate to make it through the day is considerable. And the importance of being of sound mind and body is paramount if you expect to be safe and successful on the trail here.

Candidates are repeatedly tested on everything from off-road driving skills to basic 4WD knowledge, HiLift use, and complex rigging for vehicle recovery. A variety of vehicles are used to simulate the diverse needs of future clients, and to ensure proficiency across a broad spectrum of vehicle features and functionality.

As stated earlier, Candidates are required to teach classes on all topics “on the spot” when tasked by the Cadre. The ability of each Candidate Trainer to teach anything and everything, and to effectively transfer that knowledge from Trainer to Student, is constantly evaluated while in the classroom and out on the trail. Ever changing environmental factors, fatigue, and the ingenuity of the Cadre to devise challenging scenarios adds to the fun here.

Critical Thinking is a Requirement

Real world scenarios are designed to challenge the critical thinking skills of each Candidate. Textbook answers, and winches, don’t always work out here. Moving groups of people and vehicles safely through the desert is hard work. Unexpected mobility issues and mechanical failures usually present themselves at inopportune times. When they do, the Candidates are evaluated on their ability to maintain control of the situation to include safety issues and “helpful” bystanders that are sometimes encountered on the trail.

In the back country, a loss of mobility can mean life or death, so failure is not an option for an I4WDTA Trainer.

As the late I4WDTA Master Trainer Scott Fields used to say, “Keep it moving!”

The Final Selection Board

Before the written exam is scored and the final decision is made at the TFC, Candidates are engaged on a personal level by a board of seasoned Certified Trainers. The board covers topics ranging from open ended questions to individual performance throughout the week to perceived strengths and weaknesses. Candidates are also asked direct, pointed questions about future plans for continuing education, goals in the industry, and training others if selected to join the Association. For some, this peer review is the one of the hardest parts of the entire week.

Standards and attrition are high. During the 2021 TFC, there were eight Candidates from across the USA and Canada. Every one of them is an experienced off-roader, trail guide, and leader in their own community. And they all showed up and worked hard in New Mexico.

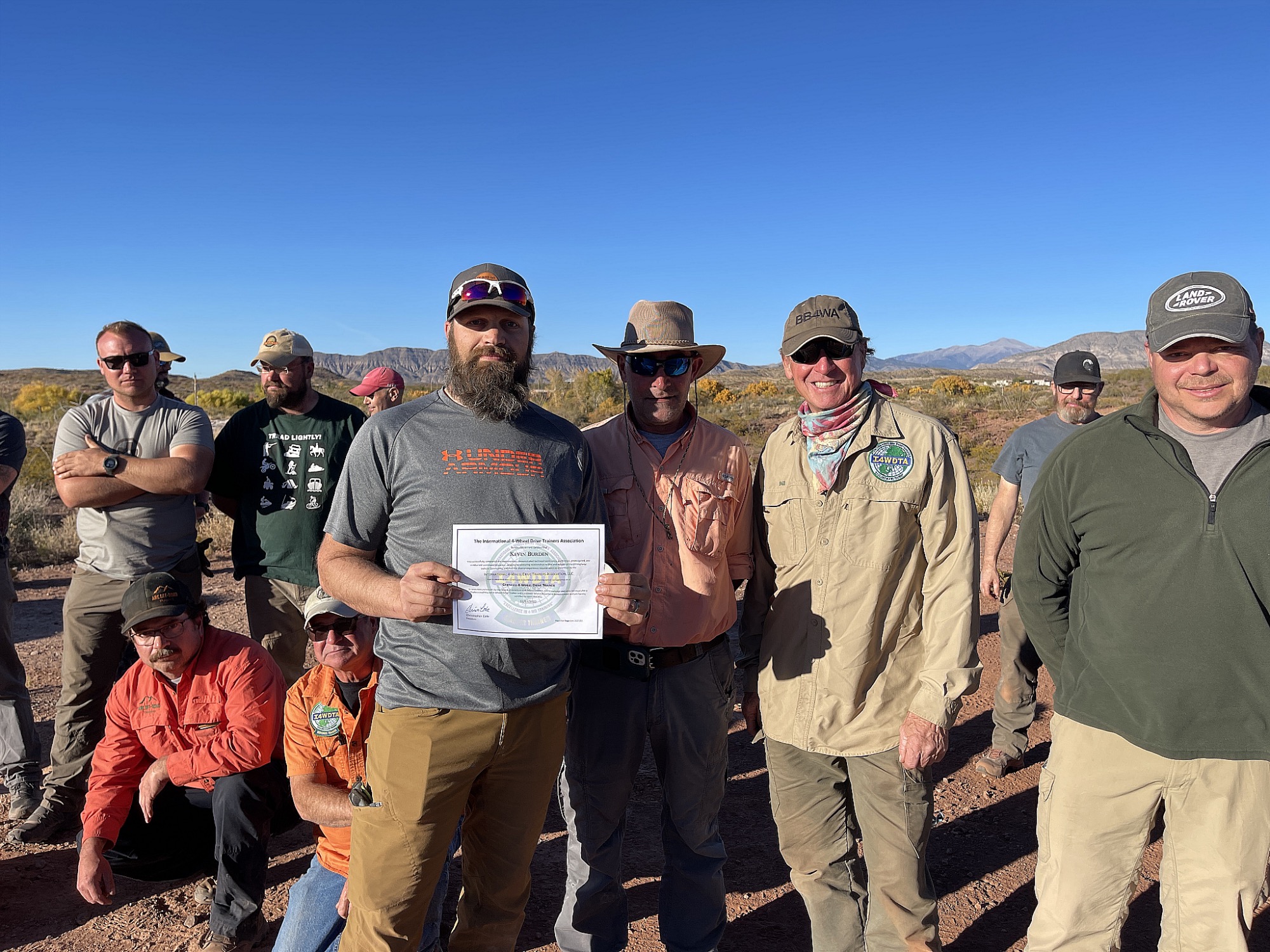

After all the scores were tabulated and discussed, the Association announced the final decision on site.

Kevin Burden was awarded Certified Trainer status. Probationary status was awarded to Mike Brent and Ben Maher, who will now pair up with a Certified Trainer for remediation, and testing, again next year.

The others didn’t make the cut.

If you’re interested in receiving training from a Certified Trainer, or if you’re ready to attend the next TFC, you can learn more HERE. Get trained and get out there!

FULL DISCLOSURE: This article is not sponsored. My travel to and from this event was entirely funded by myself for the purposes of my own continuing education, and this article I’ve written here for you. Special thanks to Chuck Davis at Survive Off Road for some of the photos featured here.

Last year, Project Tundra was fitted with a pre-production set of front and rear bumpers from a SoCal company that’s no longer in business. I spent several days at this manufacture’s location working on the install and helping to 3D scan the truck to develop additional parts like skid plates and sliders. Or at least that was the plan, but plans change. In the end Project Tundra ended up with a great set of bumpers, but no skids or sliders.

Last year, Project Tundra was fitted with a pre-production set of front and rear bumpers from a SoCal company that’s no longer in business. I spent several days at this manufacture’s location working on the install and helping to 3D scan the truck to develop additional parts like skid plates and sliders. Or at least that was the plan, but plans change. In the end Project Tundra ended up with a great set of bumpers, but no skids or sliders. The bumpers are home to some other outstanding parts, namely a bunch of Baja Designs lights, and a shiny new

The bumpers are home to some other outstanding parts, namely a bunch of Baja Designs lights, and a shiny new

Project Tundra needed sliders, and after watching

Project Tundra needed sliders, and after watching

THAT CAP AND THAT RACK

THAT CAP AND THAT RACK

At the suggestion of someone who owns a Tundra nicknamed “Monster,” Project Tundra received a SnugTop Rebel truck cap last year. Monster’s owner also happens to be in the business of importing the best roof racks around, and so Project Tundra received a K9 roof rack and supporting accouterments from

At the suggestion of someone who owns a Tundra nicknamed “Monster,” Project Tundra received a SnugTop Rebel truck cap last year. Monster’s owner also happens to be in the business of importing the best roof racks around, and so Project Tundra received a K9 roof rack and supporting accouterments from

In it’s current form, Project Tundra is an extremely versatile rig and I’m extremely happy with what I can do with it. From loading the truck up with toys and the family for long vacations to quick evening go-fast trips to the important places just to watch the sun set, Project Tundra does it all, and does it all well. This past winter, we took on record snowfalls in the Colorado Rockies, and then in the middle of summer took on the remnants of that same snow. We’ve hauled all kinds of tools and toys and enjoyed the deserts of the Southwest, and so many other great places.

In it’s current form, Project Tundra is an extremely versatile rig and I’m extremely happy with what I can do with it. From loading the truck up with toys and the family for long vacations to quick evening go-fast trips to the important places just to watch the sun set, Project Tundra does it all, and does it all well. This past winter, we took on record snowfalls in the Colorado Rockies, and then in the middle of summer took on the remnants of that same snow. We’ve hauled all kinds of tools and toys and enjoyed the deserts of the Southwest, and so many other great places.

I have to say that I feel incredibly fortunate to get to do the things that I do with Project Tundra. This whole process has created an awesome vehicle (pun intended) to get to spend time outside with good friend and family, and this whole processing of building this rig has introduced me to so many awesome folks and provided many memorable experiences that I am quite thankful for. I hope that these articles have been helpful in someway to you, whether that’s a serving of inspiration while you’re working through the daily grind or whether you’re looking into building a new rig or playing with your current setup!

I have to say that I feel incredibly fortunate to get to do the things that I do with Project Tundra. This whole process has created an awesome vehicle (pun intended) to get to spend time outside with good friend and family, and this whole processing of building this rig has introduced me to so many awesome folks and provided many memorable experiences that I am quite thankful for. I hope that these articles have been helpful in someway to you, whether that’s a serving of inspiration while you’re working through the daily grind or whether you’re looking into building a new rig or playing with your current setup!