You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Recovery Rings

- Thread starter Borrego60

- Start date

WashingtonTaco

Adventurist

Mother’s Day of 2019 we took a group of gals out for a weekend of training. One of them had the 7P recovery ring and associated soft shackle. They wanted to set up a scenario to try it out. I was curious as I had not used one before. This was a brand new never been rigged before piece of equipment.

We set up a simple redirect pull and winched a 7000 lbs Tacoma up a slope. I had a hand held thermometer and the temperature never rose above 110 degrees. Once completed we inspected the equipment and found one of 12 strands of the soft shackle (axle) completely severed. There was no visible damage to the recovery ring. I am unsure how the soft shackle was damaged. For me personally I would not spend my own money on these. I do not recommend them to clients either. The sales pitch on these is weight reduction, they are much lighter than the standard pulley blocks for sure. I am sure there is plenty of other items in your kit that you could reduce weight from the load carried or just lay off the jelly doughnuts.

We set up a simple redirect pull and winched a 7000 lbs Tacoma up a slope. I had a hand held thermometer and the temperature never rose above 110 degrees. Once completed we inspected the equipment and found one of 12 strands of the soft shackle (axle) completely severed. There was no visible damage to the recovery ring. I am unsure how the soft shackle was damaged. For me personally I would not spend my own money on these. I do not recommend them to clients either. The sales pitch on these is weight reduction, they are much lighter than the standard pulley blocks for sure. I am sure there is plenty of other items in your kit that you could reduce weight from the load carried or just lay off the jelly doughnuts.

Thoughts, anyone here use them or used them on a recovery?

Carry a real pulley block. Heat and friction are the enemy of your synthetic line.

verdesard0g

Adventurist

Never even considered those.

java230

Adventurist

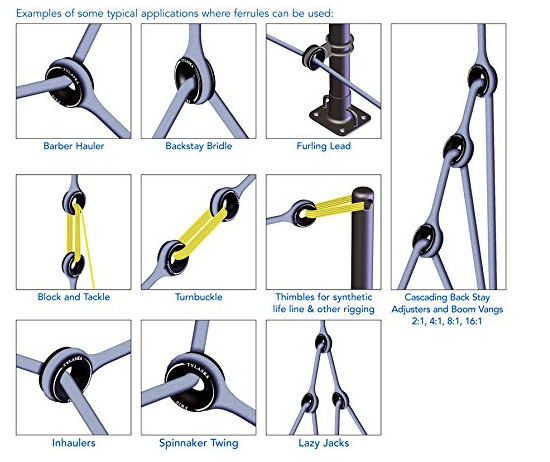

We had this thread awhile back. Found my post there, these are repurposed from sailboat rigging. Tylaska was the original maker I believe.

From the Tylaska site. Of the suggested uses none are in a pulley configuration.

Past discussion here: https://americanadventurist.com/for...r-ongoing-discussion-and-reviews.3955/page-12

From the Tylaska site. Of the suggested uses none are in a pulley configuration.

Past discussion here: https://americanadventurist.com/for...r-ongoing-discussion-and-reviews.3955/page-12

Mother’s Day of 2019 we took a group of gals out for a weekend of training. One of them had the 7P recovery ring and associated soft shackle. They wanted to set up a scenario to try it out. I was curious as I had not used one before. This was a brand new never been rigged before piece of equipment.

We set up a simple redirect pull and winched a 7000 lbs Tacoma up a slope. I had a hand held thermometer and the temperature never rose above 110 degrees. Once completed we inspected the equipment and found one of 12 strands of the soft shackle (axle) completely severed. There was no visible damage to the recovery ring. I am unsure how the soft shackle was damaged. For me personally I would not spend my own money on these. I do not recommend them to clients either. The sales pitch on these is weight reduction, they are much lighter than the standard pulley blocks for sure. I am sure there is plenty of other items in your kit that you could reduce weight from the load carried or just lay off the jelly doughnuts.

Honestly, I lost some respect for the ethics and professionalism behind "7P International" when I saw them hawking these things at Overland Expo.

These recovery rings are a total fad, and nothing but a cash grab. Shame on them for selling crapola like this to unsuspecting novices.

There. I said it.

Found some good info if you have 30min.

He reiterated several times that he is just covering efficiency and not covering wear issues on the synthetic lines. He did cover it elsewhere in essence. Here he explains why he uses rollers with his synthetic ropes instead of a hawse.

The recovery ring, soft shackle and line are creating the same situation in combination as dragging the line over a hawse fairlead. In the later of the two you make an attempt to avoid by positioning the vehicle. In the former you're doing it on purpose.

That just seems like cognitive dissonance to me. Because I picture in my head someone spending time to position the vehicles so the line spools correctly and doesn't drag across a hawse. Then using a recovery ring.

This isn't a new invention. They've literally been used in sailing for thousands of years. Some were found on a wreck of a Greek sailing ship dating back to 400 BC. They're used up in the sail rigging where being light is more important then the friction concerns.

https://www.harken.com/en/shop/lead-rings/28-mm-lead-ring/

The biggest argument I've seen is that arborists use them and I can understand it in that case. I'm not an arborist but I believe that use case has a very similar reason for their use as sailing. They're light.

In this case you can also be cutting down the thing that's supporting the rigging over your head or something may come crashing down by accident. ______ friction. You want anything up there or attached to something that's falling to be as light as possible.

That's one argument for I guess. When dodging projectiles I'd accept any margin in my favor and would choose a recovery ring over a pulley block any day.

In this case you can also be cutting down the thing that's supporting the rigging over your head or something may come crashing down by accident. ______ friction. You want anything up there or attached to something that's falling to be as light as possible.

That's one argument for I guess. When dodging projectiles I'd accept any margin in my favor and would choose a recovery ring over a pulley block any day.

Honestly, I lost some respect for the ethics and professionalism behind "7P International" when I saw them hawking these things at Overland Expo.

These recovery rings are a total fad, and nothing but a cash grab. Shame on them for selling crapola like this to unsuspecting novices.

There. I said it.

Curious if you feel the same way about Factor55 since they have their version of the pulley ring out now. Most, myself included, have the upmost respect for the team at Factor55. I think Mike has been an industry leader for a long time and is fully transparent with the research and design effort into his products. So if it truly is "crapola" and does that mean you've lost respect for Factor55 as well? No judgement either way, just curious.

Thoughts, anyone here use them or used them on a recovery?

I have the Factor55 Rope Retention Pulley in my kit. Of all the pulley rings out there I think it's the best. I like the fingers helping retain the rope in the pully which make rigging a lot easier than those without. I also like the coating on theirs which has a lower coefficient of friction when compared to standard anodized aluminum or clear-coated aluminum.

That said, I do still carry a standard pulley block in my kit as my primary pulley. So far I've only resorted to the F55 RRP when I needed to do a 3:1 or a redirect. It's not a judgement against the quality or functionality of the ring itself. I'm just more used to rigging with a standard pulley block (something about an old dog and new tricks). I also don't get stuck enough to play around with some of my new gear as much as I'd like. I also recently added their Load Distribution Plate to my kit as well and could see some neat uses for the LDP and the RRP used in tandem for some complex rigging situations.

Anyway, the key factor for me is weight savings. Ounces become pounds and pounds become tons. If I was a professional rigger using my gear day-in-day-out I'd probably stick to traditional pulley blocks or snatch blocks. However, as a casual recreationalist, the balance between lightweight and function wins out for me. At some point I could see myself replacing my heavy(er) pulley block with another RRP if/when the times comes and I'm more familiar with using the gear on a more regular basis. It doesn't hurt that I do have a background in sailing and rock climbing, so a lot of this "new fancy gear" that's hitting the off-road world has been around for a long time and I'm already used to working with it - albeit on a smaller scale.

In short, yes I have one. I'm happy with it. Looking forward to using it more in the future.

I have the Factor55 Rope Retention Pulley in my kit. Of all the pulley rings out there I think it's the best. I like the fingers helping retain the rope in the pully which make rigging a lot easier than those without. I also like the coating on theirs which has a lower coefficient of friction when compared to standard anodized aluminum or clear-coated aluminum.

That said, I do still carry a standard pulley block in my kit as my primary pulley. So far I've only resorted to the F55 RRP when I needed to do a 3:1 or a redirect. It's not a judgement against the quality or functionality of the ring itself. I'm just more used to rigging with a standard pulley block (something about an old dog and new tricks). I also don't get stuck enough to play around with some of my new gear as much as I'd like. I also recently added their Load Distribution Plate to my kit as well and could see some neat uses for the LDP and the RRP used in tandem for some complex rigging situations.

Anyway, the key factor for me is weight savings. Ounces become pounds and pounds become tons. If I was a professional rigger using my gear day-in-day-out I'd probably stick to traditional pulley blocks or snatch blocks. However, as a casual recreationalist, the balance between lightweight and function wins out for me. At some point I could see myself replacing my heavy(er) pulley block with another RRP if/when the times comes and I'm more familiar with using the gear on a more regular basis. It doesn't hurt that I do have a background in sailing and rock climbing, so a lot of this "new fancy gear" that's hitting the off-road world has been around for a long time and I'm already used to working with it - albeit on a smaller scale.

In short, yes I have one. I'm happy with it. Looking forward to using it more in the future.

I'd be really interested in seeing how shackles and lines wear with use. Especially on the shackles.

The way I see it you have two capstans. The shackle, with the way it's situated, counts as only a fraction of a turn compared to the winch lines half turn around a recovery ring. Since the shackle covers only a fraction of the arc around the capstan as opposed to the winch line it becomes the point of least resistance and the slide point.

In a 2:1 configuration that small arc is taking all the weight and friction. I'd be more comfortable doing it the way you did. A block with recovery rings to supplement.

https://en.m.wikipedia.org/wiki/Capstan_equation

I'd be really interested in seeing how shackles and lines wear with use. Especially on the shackles.

I only use mine with an abrasion guard/sheath on the soft shackle. So basically the pulley ring is rubbing on a piece of "disposable" one inch tubular webbing. If it becomes glossy from friction (which I have yet to see)or if something gets caught in there and I see some abrasion I can easily switch it out for a new piece.

That said, and take this all with a grain of salt, what I've experienced in the real world is fiction from heat comes from one of two sources: excess speed or excess load. Personally speaking, I have yet to see any measurable heat build up in any of my rigging. I'm not saying it's not possible, but I usually over-rig and under-pull (as far as speed goes) to mitigate heat and load on the components. Someone who is less careful and is running hot, heavy, and fast could easily overheat a soft shackle with a pulley ring on it, but chances are they are also going to be overloading/cooking their winch motor, alternator, battery, etc at the same time. Every recovery expert I know says to work in slow controlled "burps" as opposed to long consistent pulls. So IMHO debating heat build up in a soft shackle from a recovery ring is a moot point *IF* you're doing everything else right.

At some point I'm going to set some rigging and run my dad's FLIR on it and get some real world data to back up my anecdotal claims. So like I said, take it with a grain of salt for now since I can only speak from my personal experience with my personal gear with my style of rigging.

Curious if you feel the same way about Factor55 since they have their version of the pulley ring out now. Most, myself included, have the upmost respect for the team at Factor55. I think Mike has been an industry leader for a long time and is fully transparent with the research and design effort into his products. So if it truly is "crapola" and does that mean you've lost respect for Factor55 as well? No judgement either way, just curious.

Warn owns Factor 55 now. Their ring is just like 7P and others, even though it's "different" it's still just a fad item IMHO. They'd be foolish to not offer a competing product if people are buying them.

I don't blame companies that make gear for trying to make money, but comparing a gear company like Factor 55 to a training company like 7P is unfair. Apples to oranges.

Again, I will never use one nor recommend these "rings". I carry less optional crapola and comfort items on purpose so that I can afford to carry real needs like a proper pulley block. YMMV.

In some ways, the rings are pointless. A solution in search of a problem, marketed primarily based on “weight savings” IMO. Seems like there’s quite a few folks that really want to believe in them, or justify their inherent shortcomings vis a vis a standard pulley block.

If a guy’s load out doesn’t have the excess capacity to carry a REAL pulley block then maybe they should carry less IPA’s or other comfort based decision type crapola

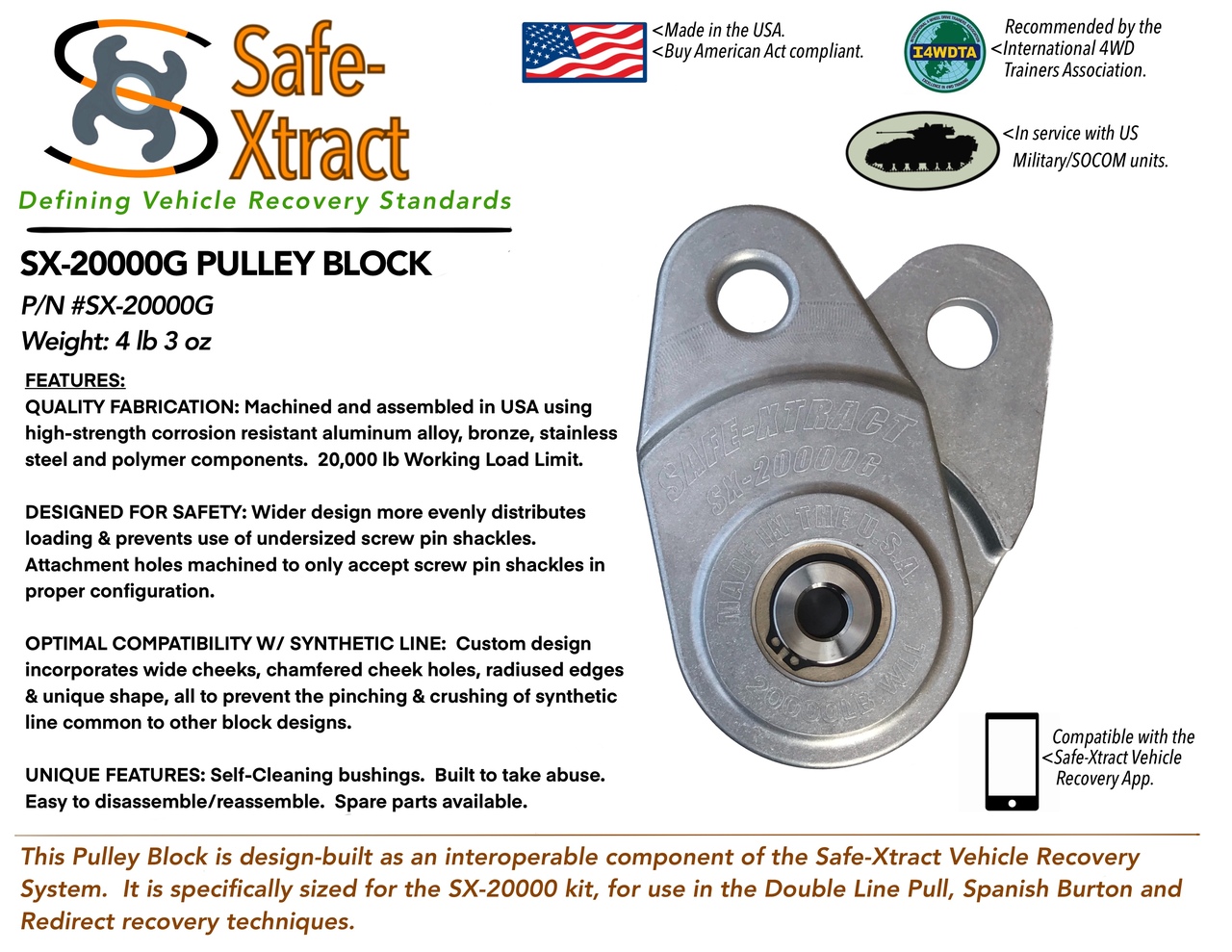

Here’s two examples of fully functional pulley blocks that barely weigh anything.

1 lb 9 oz, 8000 lb rating

4 lbs 3 oz, 20,000 lb rating

If a guy’s load out doesn’t have the excess capacity to carry a REAL pulley block then maybe they should carry less IPA’s or other comfort based decision type crapola

Here’s two examples of fully functional pulley blocks that barely weigh anything.

1 lb 9 oz, 8000 lb rating

4 lbs 3 oz, 20,000 lb rating