You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

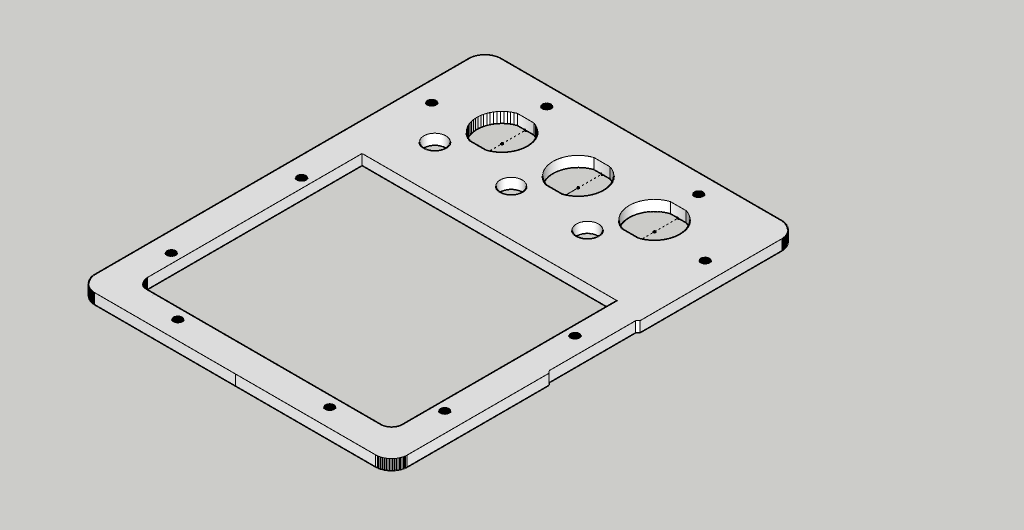

Prototype Battery Box

- Thread starter Greg

- Start date

A little more refined than taking a cutting wheel and file to a sheet of ABS plastic. The prototype buried the fuses behind the panel. The printable version has a place for a Blue Sea 5021 Fuse Holder next to each of the socket cutouts.

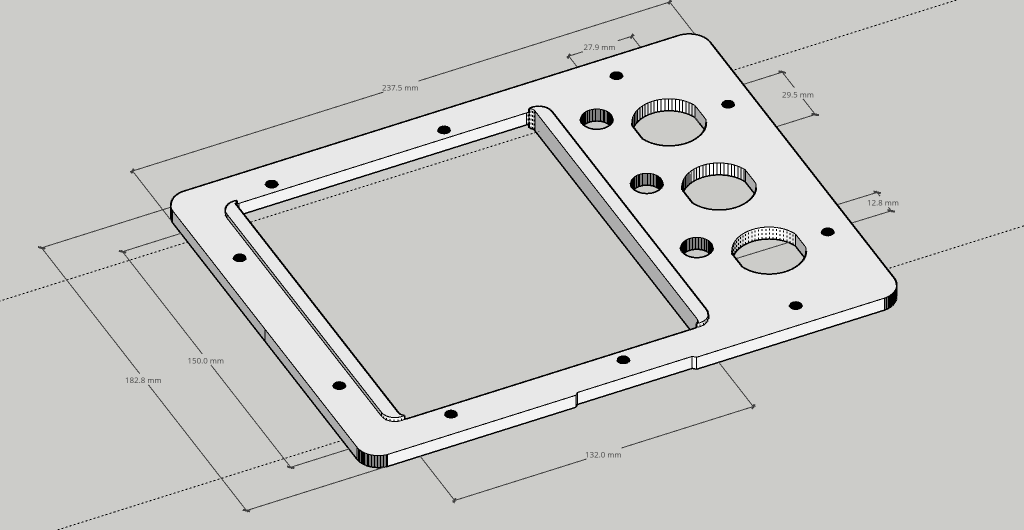

This panel is sized for the Antigravity ATX-12-HD lithium battery and Pelican 1200 case with frame mount.

This panel is sized for the Antigravity ATX-12-HD lithium battery and Pelican 1200 case with frame mount.

Designed to fit the following 3 batteries.

3D Printing will cost about $90-95 + shipping. Looking for a cheaper solution like CNC.

- Antigravity YTX12-24 Lithium Battery - 25Ah - 150x87x130mm

- Antigravity YTX12-20 Lithium Battery - 22Ah - 150x87x130mm

- Antigravity ATX-12-HD RE-START Lithium Battery - 16Ah - 150x86x132mm

3D Printing will cost about $90-95 + shipping. Looking for a cheaper solution like CNC.

Instead of the glass AGC fuses, might I suggest...

https://www.bluesea.com/products/category/14/26/Circuit_Breakers/Push_Button_Reset-Only

or

https://www.bluesea.com/products/category/14/27/Circuit_Breakers/Medium_Duty

https://www.bluesea.com/products/category/14/26/Circuit_Breakers/Push_Button_Reset-Only

or

https://www.bluesea.com/products/category/14/27/Circuit_Breakers/Medium_Duty

How many are you looking to print and what materialDesigned to fit the following 3 batteries.

View attachment 41613

- Antigravity YTX12-24 Lithium Battery - 25Ah - 150x87x130mm

- Antigravity YTX12-20 Lithium Battery - 22Ah - 150x87x130mm

- Antigravity ATX-12-HD RE-START Lithium Battery - 16Ah - 150x86x132mm

3D Printing will cost about $90-95 + shipping. Looking for a cheaper solution like CNC.

I've contacted a few places. Roughly $80 for CNC cut 1/4" ABS for a 1 off. Shapways will print and ship on demand and they're running around the same price when shipping is added. I'm not worried about the quality of the printed plastic. I've have other items printed by Shapways in the past and that plastic is pretty tough.

I have one CNC cut (fuse) and one printed (reset) on their way along with the Blue Sea push button resets and AGC/MDL fuse holders. When I get them in hand, compare them, and make sure everything fits I'll go from there. I'm leaning toward Shapways. CNC cut would be cheaper to mass produce but then I'd have to deal with storing and shipping them myself. I'd also have to pay for it up front and hope I sell enough to cover the cost of making them.

I have one CNC cut (fuse) and one printed (reset) on their way along with the Blue Sea push button resets and AGC/MDL fuse holders. When I get them in hand, compare them, and make sure everything fits I'll go from there. I'm leaning toward Shapways. CNC cut would be cheaper to mass produce but then I'd have to deal with storing and shipping them myself. I'd also have to pay for it up front and hope I sell enough to cover the cost of making them.

I wonder if they have one with a larger table. The 18cm width barely fits the 1200 case. You know if I get something like this I'm gonna want to make stuff for the 1300 and 1400 cases too

PM Sent.I would be willing to bet that I can print it far cheaper than $90. Send me a pm

This was the results of the Antigravity ATX-12-HD RE-START powering a 37 Quart ARB fridge with a transit bag cover. It's contents during the test was 2 plastic bottles containing about 3 quarts of water. The fridge was run on 120V until everything was at the target temperature of 0 degrees celsius. During the test the fridge was not opened. At 12.85V the batteries RE-START feature triggered preventing further drain of the battery until reset.

13.77V - 0H - 12:44 - Just off the charger

13.27V - 1H 5M

13.17V - 3H 25M

13.13V - 4H 31M

13.11V - 5H 51M

13.10V - 7H 11M

12.92V - 9H 20M

12.85V - 10H 15M - 22:59 - Battery RE-START feature triggered

Last edited:

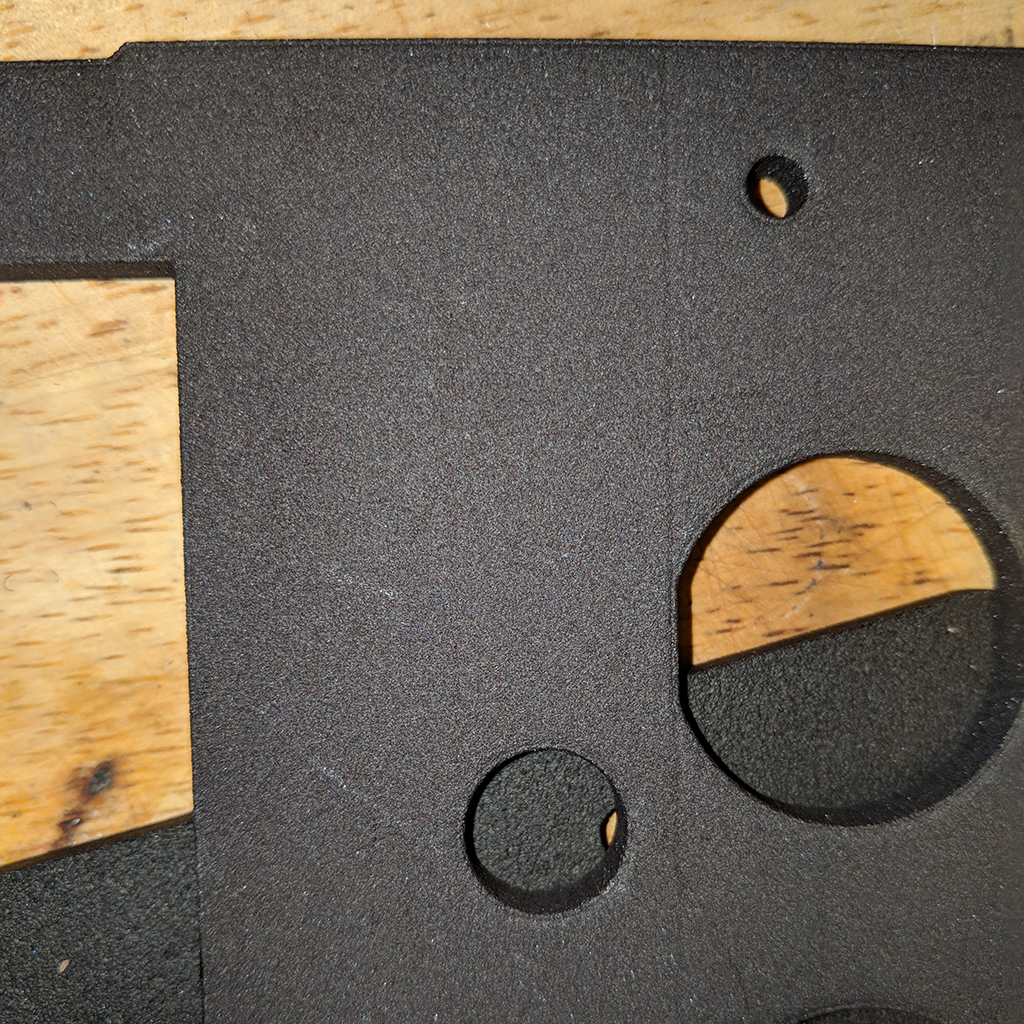

Production versions checks out. Tolerance is tight but everything fits.

This is the CNC ABS production version.

The printed panels on Shapways (below) are the same spec as the CNC cut ABS plastic above. Same tight tolerance. Everything fits and they're about 15% cheaper in cost until Jan 2019. Then there will be a price change on Shapways. Depending on how much of a change in price will determine what I do next. Maybe do something like group buys for the CNC cut versions if printing is to expensive.

This is the CNC ABS production version.

The printed panels on Shapways (below) are the same spec as the CNC cut ABS plastic above. Same tight tolerance. Everything fits and they're about 15% cheaper in cost until Jan 2019. Then there will be a price change on Shapways. Depending on how much of a change in price will determine what I do next. Maybe do something like group buys for the CNC cut versions if printing is to expensive.

Last edited:

Is there a reasonable option to build one that has two 12v batteries that can be wired in series?

I currently have two motorcycle batteries in a marine battery box that I use to wire in series to get 24v for my RediWelder. The box is HEAVY but it's a lot more portable and generally easier to lug around than it is to take a battery out of a vehicle and then set up with another battery to get the 24v.

I'll have to look to see what size batteries I'm currently using. I've used the current set up once, it turned into a booger weld patch job trying to weld an axle tube back on to an axle housing using wrenches and whatever else could be found to use as gusset material. I'll see if I can dig up some specs for the RediWelder as well. My needs are more likely to be an exception and cost prohibitive. Just brainstorming the idea.

I currently have two motorcycle batteries in a marine battery box that I use to wire in series to get 24v for my RediWelder. The box is HEAVY but it's a lot more portable and generally easier to lug around than it is to take a battery out of a vehicle and then set up with another battery to get the 24v.

I'll have to look to see what size batteries I'm currently using. I've used the current set up once, it turned into a booger weld patch job trying to weld an axle tube back on to an axle housing using wrenches and whatever else could be found to use as gusset material. I'll see if I can dig up some specs for the RediWelder as well. My needs are more likely to be an exception and cost prohibitive. Just brainstorming the idea.

The Antigravity YTX12-24 lithium battery (25Ah) is 5 lbs, 6 x 4 x 6 inches, but it's about $360. I suppose you could find another lithium battery cheaper and about the same size and capacity. Perhaps a little heavier. e.g. Shorai Batteries. Pick your battery and then build around it. That's what I did for this starting with my old bike battery.

https://www.pelicancasesforless.com/t-pelican-case-sizes.aspx

https://www.pelican.com/case_calculator.php

https://www.pelicancasesforless.com/t-pelican-case-sizes.aspx

https://www.pelican.com/case_calculator.php