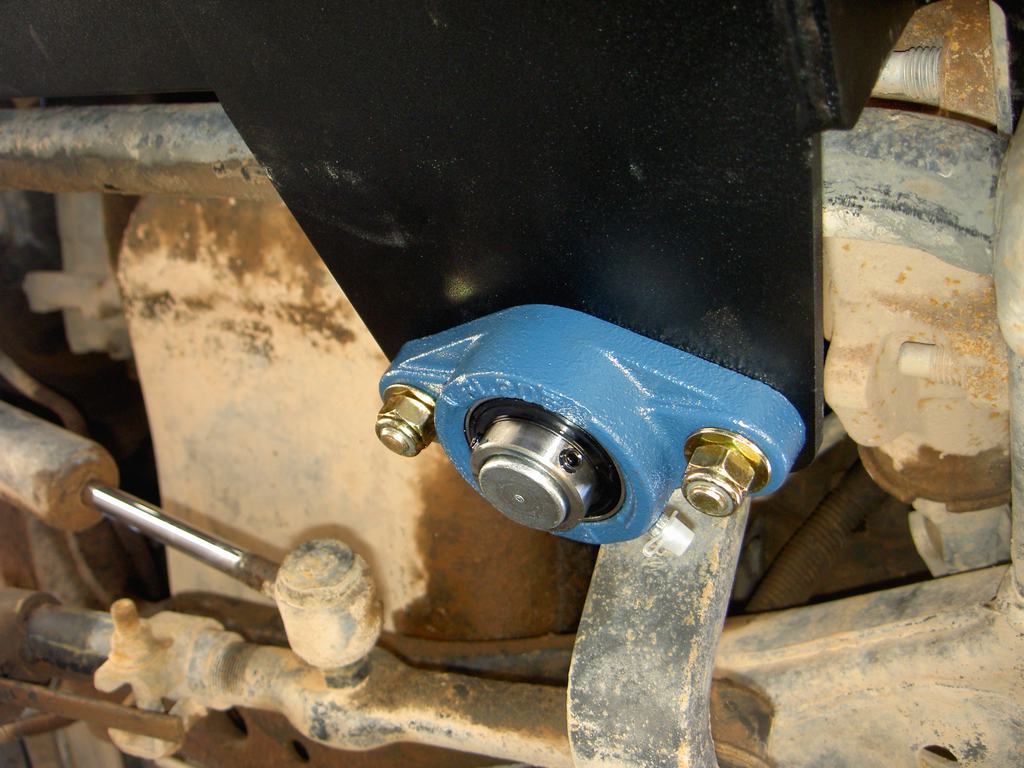

I never got around to posting this as I didn't realize I took pics. Found them last night so figured I would post up some work I did back in Oct. last year. After getting the steering linkage swapped in, during the alignment we found some issues with the brakes. I ended up replacing the hubs, rotors, calipers, pads but did not get the braided brake lines in as I was running on a deadline and there are a couple hard lines I was afraid might have issues coming apart. I also am trying out the new Hawk SD pads which are supposed to be for severe duty. Outside of the first couple of stops being long due to the pads being cold, once a little heat is in them, the work very well.

Old parts - actually found the pass. side one, the rotor was rotating on the hub due to someone incorrectly pressing the studs in

Pads almost gone and torn caliper boots

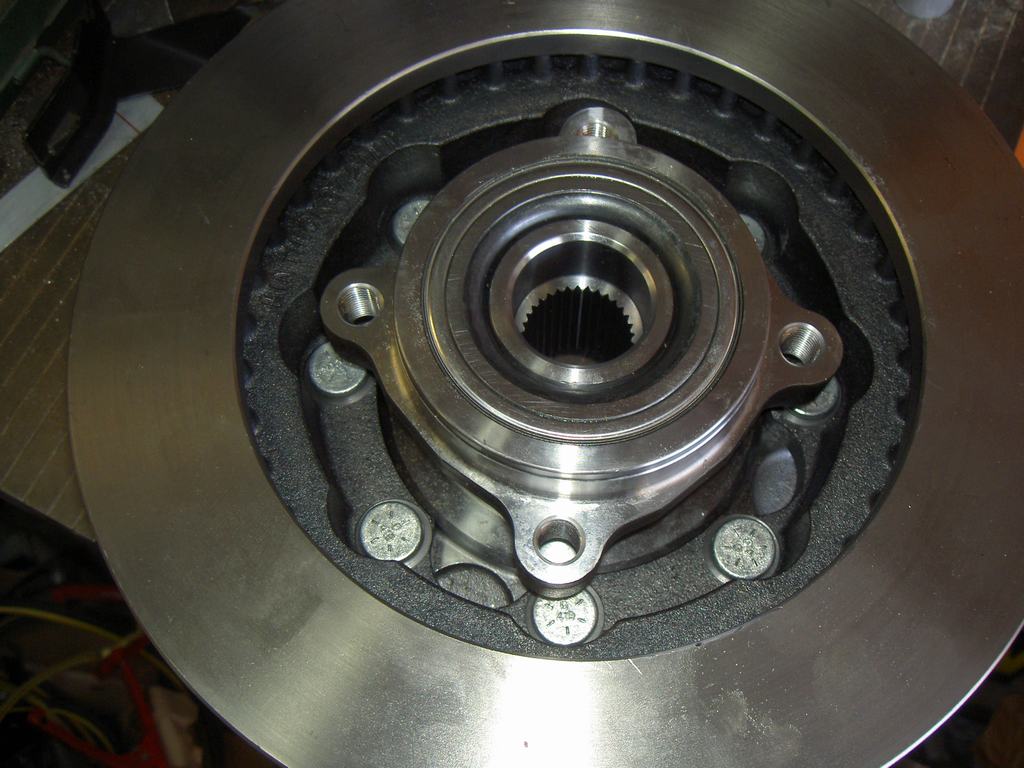

Many hundreds of dollars worth of parts. By replacing everything, I could assemble the hubs/rotors prior to disassembling the old ones.

Unlike slip on rotors, the hubs slide in from the front and the studs push through from the back, to lock the rotor between them. Not very user friendly needless to say!

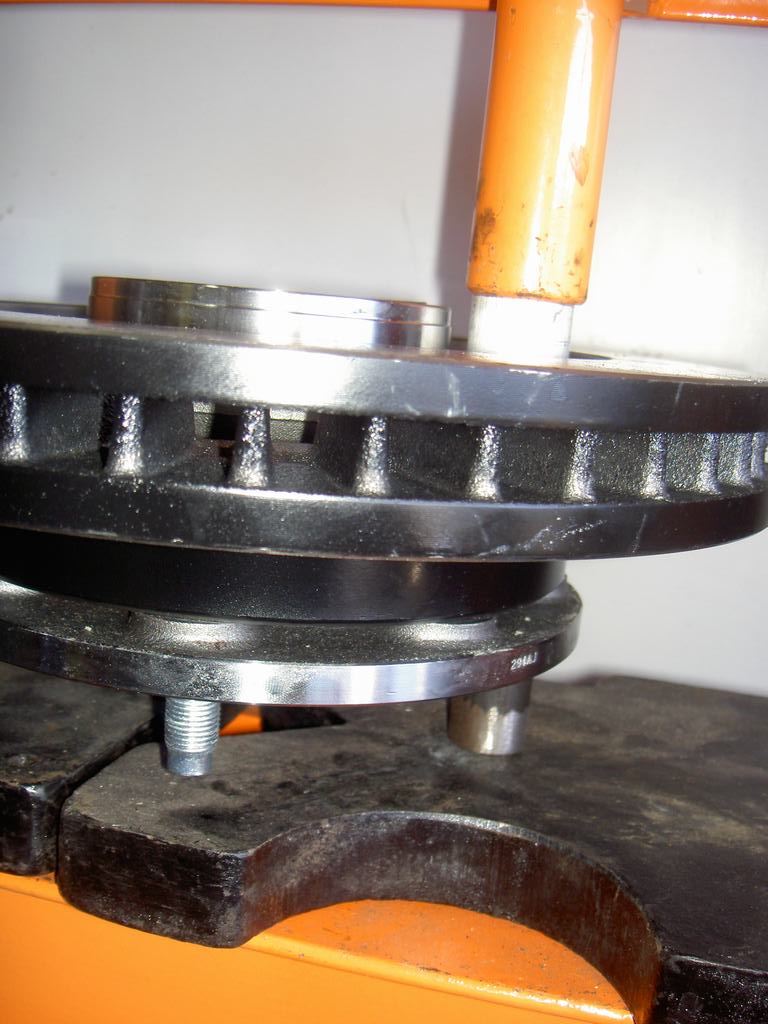

Used Grade 8 nuts and washers to start pulling the studs through.

Pieces I machined up to allow me to push in the studs on my press

Stud through the tubing, solid piece pushing on the back of the stud. One down... 15 to go

One rotor completed

I had big problems getting the axle nuts off. Breaker bar with 4' long pipe didn't budge them. My Snap-On 600 ft. lbs. impact did not budge them. I had to go out and buy a BIG impact wrench!!! It got them off

Old hub and rotor off

New hub, rotor, caliper and pads installed. Still needed to put the cotter pin back in