ARB 2500 Awning Review

It’s often said that imitation the sincerest form of flattery and I find that to be very true in this case. I have always considered ARB to be the gold standard for vehicle mounted awnings. Last time I did a quick internet search I came up with about 6 different manufactures producing vehicle awnings that look to be almost exact duplicates of the ARB! The big difference that sets ARB apart from the rest of its competitors is customer service and product innovation.

The most resent update of the old tried and proven awning came October of 2016. I was a bit apprehensive and excited to get my hands on one of the new models. The first thing you will notice is that the awning bag has a new sleeker design that gives it a nice compact look. Also the zipper extends all the way to the ends of the bag and have a little pockets that helps to protect them in addition to keeping the clanking of the zipper tabs down. When I first unboxed the awning and bolted it up I instantly loved the new trim look, but I was worried it would be harder to roll back up into the new smaller awning bag. Well I was wrong it is still just as easy to roll up and stow as the old design.

The other notable new additions are the one piece molded end cap which helps prevent snagging when attaching the many available accessories to the awning sail tracts. There is also a section of reinforced material where the canvas of the awning attaches to the aluminum base plate to help minimize any abrasion. Additionally the mounting extrusion has been beefed up with a reinforced button head bolt and nylon nut aide in reducing any flexibility. We personally put that feature up to the test, well we didn’t but the maintenance department at the Toyota dealer did. When we dropped my wife’s 4Runner off to be serviced they “accidently” took it through an automated carwash that ripped the waning off of our roof rack. The awning held up like a champ with only a couple of small nicks in the bag and a very slight bow to the aluminum base plate. Now the roof of the 4runner had quite a few extra dents and the stock roof rack took a good beating. The awning is now mounted to the driver’s side of our Four Wheel Camper Swift and makes for a very spacious shower room.

The amount of shade that the 2500 awning produces is simply amazing and a welcomed addition during the hot summer months. However it does come at a price, the same reason that causes it to produce almost an acer (8.2ftx8.2ft) of shade makes it very tuff to deploy and stow due to its large size. I have read about some folks being able to deploy and stow it single handedly but for the life of me I can’t figure it out. So for the time being we use the two person technique which is quick, simple and effective. Bottom line is that out of the three different awnings we have owned this one is an outstanding awning packed with features at an incredible price. Its one piece of kit you will rarely think about but it has the ability to change the mood of the whole camping trip!

Standard features taken directly from the ARB webpage:

View attachment 34262

It’s often said that imitation the sincerest form of flattery and I find that to be very true in this case. I have always considered ARB to be the gold standard for vehicle mounted awnings. Last time I did a quick internet search I came up with about 6 different manufactures producing vehicle awnings that look to be almost exact duplicates of the ARB! The big difference that sets ARB apart from the rest of its competitors is customer service and product innovation.

The most resent update of the old tried and proven awning came October of 2016. I was a bit apprehensive and excited to get my hands on one of the new models. The first thing you will notice is that the awning bag has a new sleeker design that gives it a nice compact look. Also the zipper extends all the way to the ends of the bag and have a little pockets that helps to protect them in addition to keeping the clanking of the zipper tabs down. When I first unboxed the awning and bolted it up I instantly loved the new trim look, but I was worried it would be harder to roll back up into the new smaller awning bag. Well I was wrong it is still just as easy to roll up and stow as the old design.

The other notable new additions are the one piece molded end cap which helps prevent snagging when attaching the many available accessories to the awning sail tracts. There is also a section of reinforced material where the canvas of the awning attaches to the aluminum base plate to help minimize any abrasion. Additionally the mounting extrusion has been beefed up with a reinforced button head bolt and nylon nut aide in reducing any flexibility. We personally put that feature up to the test, well we didn’t but the maintenance department at the Toyota dealer did. When we dropped my wife’s 4Runner off to be serviced they “accidently” took it through an automated carwash that ripped the waning off of our roof rack. The awning held up like a champ with only a couple of small nicks in the bag and a very slight bow to the aluminum base plate. Now the roof of the 4runner had quite a few extra dents and the stock roof rack took a good beating. The awning is now mounted to the driver’s side of our Four Wheel Camper Swift and makes for a very spacious shower room.

The amount of shade that the 2500 awning produces is simply amazing and a welcomed addition during the hot summer months. However it does come at a price, the same reason that causes it to produce almost an acer (8.2ftx8.2ft) of shade makes it very tuff to deploy and stow due to its large size. I have read about some folks being able to deploy and stow it single handedly but for the life of me I can’t figure it out. So for the time being we use the two person technique which is quick, simple and effective. Bottom line is that out of the three different awnings we have owned this one is an outstanding awning packed with features at an incredible price. Its one piece of kit you will rarely think about but it has the ability to change the mood of the whole camping trip!

Standard features taken directly from the ARB webpage:

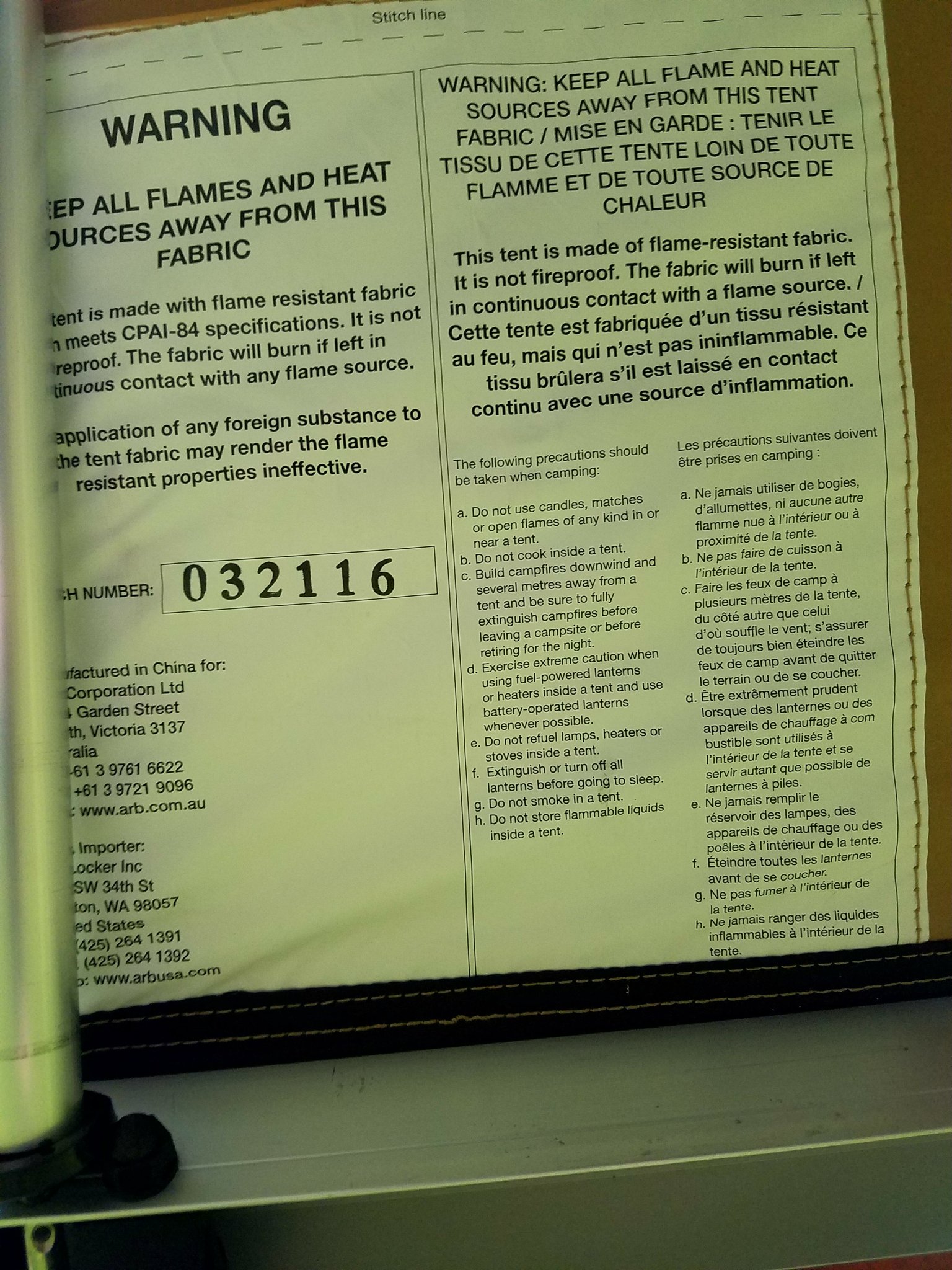

- Conforming to the stringent fabric flammability standards of the North American

market, each batch of material used in the ARB roof top tent, awning or awning accessory is tested by an independent certified body (SGS) in accordance with international CPAI-84 standards and specifications. The benefit of flame retardancy is an assurance that if an ember from a nearby fire was to fall onto the material, your ARB product should not ignite, but if it does it will in fact self extinguish.

- Flexible arm/leg hinge joints. This helps to prevent damage to the arms and legs of the

awning in the unlikely event that the awning is not secured properly. Brittle plastic or aluminum joints used by the majority of our competitors usually result in damage to the poles or the main awning extrusions.

- Clear anodized aluminum. This prevents the possibility of corrosion in the arms or legs

which results in jamming when trying to extend or retract and arm/leg.

- PU coated 300 GSM poly cotton rip stop canvas. PU (Polyurethane) is a coating that

makes the canvas impervious to water at hydrostatic head ratings above 1500mm. That’s

far more water than the awning structure could ever be designed to cope with.

- PVC reinforcement panels and plastic nut caps. The awning outer beam is designed to be

rolled over the canvas when stowing. The addition of the PVC patches and nut caps prevent the awning legs and hinge joint assembly from rubbing on the canvas in severe conditions.

- UPF50+ Ultraviolet Protection Rating. This is the highest rating achievable for fabrics

and equates to 97.5 - 98% blocking of UV rays .

- 2mm thick awning beam extrusions. Many competitor products use only 1mm thick

extrusions making them weaker in hinge areas and more prone to damage.

- 900 GSM UV stable laminated PVC cover. Enhanced durability, UV and water

resistance.

View attachment 34262

Last edited: